BVV

-

3 Gallon Vacuum Chamber Digital Heating Jacket

3 Gallon Vacuum Chamber Digital Heating Jacket A vacuum chamber heating jacket provides the user the ability to evenly heat the chamber around the circumference while being very stable and when combined with a heating pad it covers most of the vessel distributing heat on what is being degassed in the vessel. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Temp: 160F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 7.9"W x 33.9"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes This product comes with the Digital Heating Jacket ONLY, does not include the chamber.

$364.13

-

3 Gallon WIDE Stainless Steel - POT ONLY

3 Gallon WIDE Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Wide Stainless Steel Vacuum and Degassing Chamber SVac 3 Gallon Wide Stainless Steel Vacuum Chamber Dimensions: 8" Tall x 10.5" Diameter Material: 304 Stainless Steel

$75.63 - $81.23

-

3 Gallon WIDE Stainless Steel SIDEMOUNT - POT ONLY

3 Gallon WIDE Stainless Steel SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Wide Stainless Steel Side Mount Vacuum and Degassing Chamber Glass Vac 3 Gallon Aluminum Vacuum Chamber Dimensions: 9" Tall x 10.75" Diameter Hole Size: 21/64 Material: 304 Stainless Steel

$81.23 - $109.24

-

3 Neck Heavy Wall Round Bottom Flask - USA Made

3 Neck Heavy Wall Round Bottom Flask - USA Made This USA made 3 Heavy Wall Round Bottom Flask is designed specifically for Short Path Distillation units and allows dual distillation heads and cows so there is more vapor flow from the heating mantle. These flasks are made of heavy walled borosilicate. Specifications Material Heavy Wall Borosilicate Sizes Available: 10000ml - 24/40 Center Joint and 34/45 Side Joints 20000ml - 24/40 Center Joint and 45/50 Side Joints MADE in the USA *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$560.19 - $840.29

-

3 Piece Heavy Duty 8" Tri-Clamp 304SS

3 Piece Heavy Duty Tri-Clamp/Tri Clover 304SS This 3 Piece Heavy Duty Tri-Clamp is made out of 304 stainless steel and has a 3 segment locking function allowing even pressure around the connection point gasket so it does not bulge out in a certain direction creating a better overall seal on the system. This clamp will fit a standard 8" tri-clamp connection

$112.04 $70.02

-

3" Dewaxing Closed Column 180G-2LB

DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. DO NOT USE INDOORS Key Features and Description: Closed Column Pressure Extractor (Comes with 1 yr. Limited warranty, excludes gaskets and screens) Compound Gauge with (-30)-160 PSI readout. This system allows the user to build up solvent pressure by closing the valve, pulling a vacuum and filling the extractor, Extractor will fill about 85% with solvent before the internal pressure will equal the pressure of the can propellant. The solvent can will fit into either port with a tip adapter supplied with some butane cans, tip adapter required, not included Solvent Soak is expected to be between 30-90 min, but this all depends on material, starting with frozen cans of solvent is recommended This system allows the user to soak the material before opening the bottom valve to release the solvent and oil. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Explorer Kit Includes the Following: 8" x 8" Platinum Cured Silicone Non-Stick Pad 3" Dewaxer Tri-Clamp 304 Stainless Steel Material Tube Spool Sizes Specifications: 3" x 6" Dewaxer = 180G 3" x 12" Dewaxer = 350G 3" x 24" Dewaxer = 1LB 3" x 36" Dewaxer = 2LB 304 Stainless Steel Flare End Caps with Heavy Duty Stainless Steel Miniature Ball Valves Hemispherical Reducer 1/4" Stainless Steel MNPT Drain Plug (2) 3" Standard Pressure Tri-Clamp Clamps 1.5" Tri-Clamp Quadpod (2) Buna-N Tri-Clamp Gaskets Buna-N 100 Mesh (150 Micron) Gasket *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. ***Note: Parts and components can be subject to substitutions. Any substituted parts will have the same function and will be of equal or greater value.****

$312.31 - $505.58

-

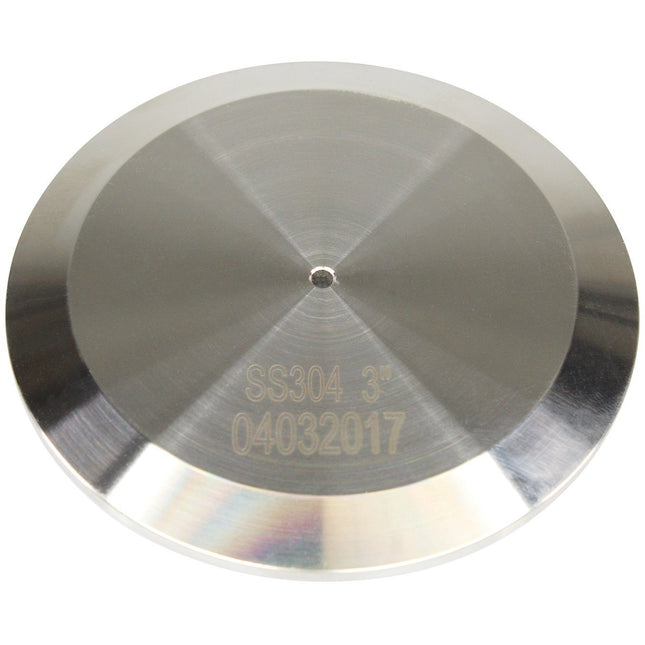

3" Open Blast Extractors 180g-1LB

3" Open Blast Extractors 180g-1LB Open Blast Extraction is an economical method with allows for instant extraction of plant material these columns are designed with ease of use in mind. These Extractors come with a Material Tube, 1x Mesh Buna Gasket, 1 Regular Buna Gasket, Quadpod, Clamp, Tri Clover, Ferrule, 8" x 8" Silicone Pad, and Open Blast Top Cap. All Stainless Steel components are made out of 304 Grade Stainless Steel. Ideal for plant oil extraction. Optional Upgrade(s): Showhead Upgrade: Allows the solvent to be spread more evenly through the plant material inside the column. What's Included?: 3" Solid Endcap with 3mm Hole Standard Pressure Clamp Material Tube (User Can Upgrade Capacity Through Dropdown Options) 3" Tri-Clamp Quadpod 3" Ferrule 8" x 8" Silicone Pad 3" Buna N 100 Mesh Gasket (150 Micron) 3" Buna-N Gasket *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$140.05 - $196.07

-

3" Standard Closed Column Extractor 180G-2LB

DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. DO NOT USE INDOORS 3" Standard Closed Column Extractor 180G-2LB Key Features and Description: Closed Column Pressure Extractor (Comes with 1 yr. Limited warranty, excludes gaskets and screens) Compound Gauge with (-30)-160 PSI readout. This system allows the user to build up solvent pressure by closing the valve, pulling a vacuum and filling the extractor, Extractor will fill about 85% with solvent before the internal pressure will equal the pressure of the can propellant. The solvent can will fit into either port with a tip adapter supplied with some butane cans, tip adapter required, not included Solvent Soak is expected to be between 30-90 min, but this all depends on material, starting with frozen cans of solvent is recommended This system allows the user to soak the material before opening the bottom valve to release the solvent and oil. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Explorer Kit Includes the Following: 8" x 8" Platinum Cured Silicone Non-Stick Pad 3" Tri-Clamp 304 Stainless Steel Material Tube Spool Sizes Specifications: 3" x 6" = 180G 3" x 12" = 350G 3" x 24" = 1LB 3" x 36" = 2LB 304 Stainless Steel Flare End Caps with Heavy Duty Stainless Steel Miniature Ball Valves Hemispherical Reducer (2) 3" Standard Pressure Tri-Clamp Clamps 1.5" Tri-Clamp Quadpod (2) Buna-N Tri-Clamp Gaskets Buna-N 100 Mesh (150 Micron) Gasket *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. ***Note: Parts and components can be subject to substitutions. Any substituted parts will have the same function and will be of equal or greater value.****

$240.88 - $371.13

-

3" Tri-Clamp Dewaxer Columns

3" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 3" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 3" x 6" Tri-Clamp Dewaxer Column 3" x 8" Tri-Clamp Dewaxer Column 3" x 12" Tri-Clamp Dewaxer Column 3" x 18" Tri-Clamp Dewaxer Column 3" x 24" Tri-Clamp Dewaxer Column 3" x 36" Tri-Clamp Dewaxer Column Specifications: Tri-Clamp Size 3" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 5.000" Spool ID 2.870" Spool OD 3.000" Flange OD 3.579" Bead Center 3.281" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 3" Tri-Clamp Dewaxer Columns - Drawing

$126.04 - $336.12

-

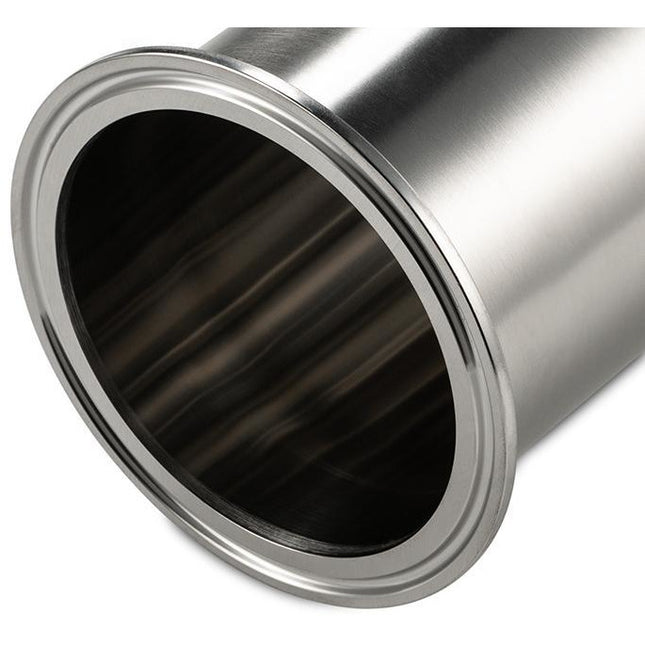

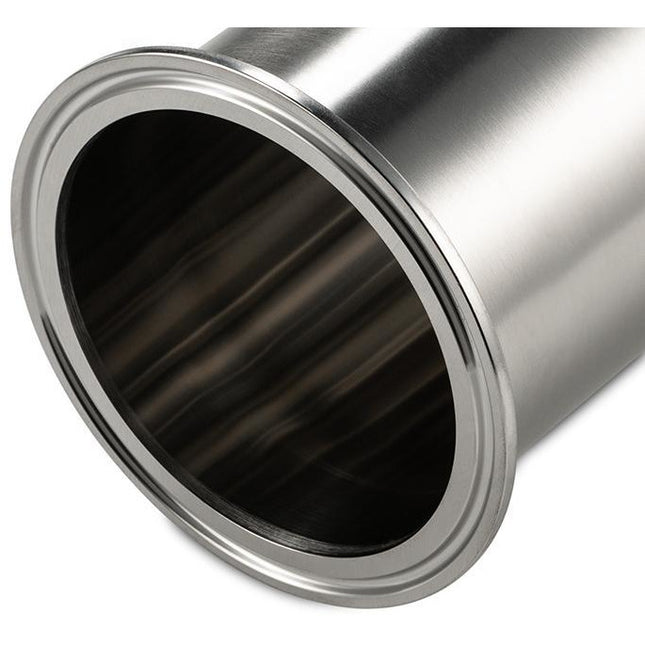

3" Tri-Clamp Spools

3" Tri-Clamp/ Tri Clover Spools Sizes Available: 3" x 2" Tri-Clamp Spool 3" x 6" Tri-Clamp Spool 3" x 9" Tri-Clamp Spool 3" x 12" Tri-Clamp Spool 3" x 18" Tri-Clamp Spool 3" x 24" Tri-Clamp Spool 3" x 36" Tri-Clamp Spool 3" x 48" Tri-Clamp Spool Specifications Tri-Clamp Size 3" Material 304 Stainless Steel Standard 3A High Polish Spool OD 3" Spool ID 2.87" Flange OD 3.579" Bead Center 3.281" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 3" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butae by Size Pounds of mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$35.01 - $189.07

-

3" Tri-Clamp x (2) 1/4" FNPT

3" Tri-Clamp/ Tri Clover x (2) 1/4" FNPT These End Caps come with Two 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Specifications Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 3" BVV™ 3" Tri-Clamp x (2) 1/4" FNPT - Drawing BVV™ 3" Tri-Clamp x (2) 1/4" FNPT - End Cap Chart

$54.62

-

3" Tri-Clamp x (2) 1/4" FNPT Ports w/ Shower Head

3" Tri-Clamp/ Tri Clover x (2) 1/4" FNPT Ports w/ Shower Head These End Caps come with Two 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Stainless steel tri-clamp fittings are the most popular style of process line equipment used within the industrial, food, beverage, and pharmaceutical industries. Shower Head End Caps help disperse solvent input into a system, which creates better material saturation when flooding a material column. This helps to prevent channeling, ensuring all the material is saturated. Quickly create a leak-proof connection allowing easy assembly or disassembly for routine maintenance and inspection. Specifications Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 3"

$42.01 $28.01

-

3.3 Gallon Square 11/16" Acrylic Wall Vacuum Chamber

Acrylic Vacuum Chamber This chamber comes with or new industrial-grade, Die Cut Neoprene Gasket. This Chamber will lose no more than 2.5Hg (inches of Mercury) every 24 hours. This is a complete vacuum chamber and will come assembled for instant use, it is ideal for degassing mixed liquids and small parts. With transparent 11/16" thick acrylic walls, this vacuum chamber provides durability and visibility of all parts. We are the number one provider in the market for shatter vac vacuum chambers because of our great customer service, quick turnaround time, safety, and unbeatable warranty. We monitor our listings daily and have a reputation for responding to all inquiries very fast and accurately. Our high demand and volume allow us to beat any price in the market, all while ensuring you always receive a superior product. You will receive the best products available because all of our suppliers are ISO 9000 certified for quality control management and because we take great pride in our vacuum chamber systems.Internal Dimensions: 10.5" Long X 10.5" Wide X 7" DeepThis chamber comes assembled and includes: (1) 1/2" thick clear acrylic lid (1) Die Cut Neoprene Gasket (1) 8" x 8" Silicone Pad (1) 50 Micron Air Filter (1) Custom glycerin filled vacuum gauge Max vacuum -29.5Hg (+/-0.5Hg) (1) Leak-free nickel-plated air manifold with extra vacuum release valve (1) 5ft HVAC Hose for Vacuum

$784.27

-

3.5CFM Dry Floating Scroll Vacuum Pump #1 Candy Drying Vacuum Pump

3.5CFM Dry Floating Scroll Vacuum Pump 1 Candy Drying Vacuum Pump Oil and Maintenance Free! Introducing the BSVF6 Vacuum Pump, equipped with cutting-edge patented floating scroll technology for unparalleled performance. This pump boasts a 3.5CFM (100 L/min) pump speed and an ultimate pressure of 25 Microns (≤ 0.03 mbar), making it a powerhouse in creating and maintaining vacuums. The 100% oil-free design ensures clean and efficient operation, while the brushless DC motor, with 350W motor power and 200W installed power, provides reliability and longevity. With a compact size ideal for portable equipment, this vacuum pump offers unlimited vapor tolerance and a noise level as low as 55 dB(A) with its case. The SVF-E2-100 is maintenance-free, featuring a robust build with inlet/outlet connections in KF-25, air-cooled cooling system, and a wide ambient temperature range from -40ºC to 50ºC. Elevate your vacuum processes with this advanced, compact, and powerful solution. Specifications Model BSVF6 Pump Speed 100 L/min Ultimate Pressure ≤ 0.03 mbar (25 Micron) Motor Power 350 W Installed Power 200 W Motor Type Brushless DC Motor DC Voltage 48 VDC AC Voltage (with adapter) 100 – 240 VAC Maximum Speed 4000 RPM Vapor Tolerance Unlimited Maximum Inlet Speed Unlimited Maximum Outlet Speed 1 barg Noise Level (With Frame) 60 dB(A) Noise Level(With Case) 55 dB(A) Weight (With Frame) 7.5 kg Weight (With Case) 8.5 kg Dimensions (With Frame) 324×225×175mm Dimensions (With Case) 394×236×189mm Inlet/Outlet Connection KF-25 or G 3/8″ Cooling System Air – Cooled Ambient Temperature -40ºC to 50ºC

$2,170.75

-

3/4" 37 Degree x 48" Length JIC Braided Stainless Steel Hose

3/4" 37 Degree JIC Braided Stainless Steel Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Specifications: Connection Type(s): 3/4" 37° Female JIC Swivel (1 1/16"-12) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65° to 450°F Pressure Rating 1200 PSI Chemical Resistance Excellent Max Bend Radius 7-3/4"

$224.08

-

3/8" 316SS Hard Line Tubing 5FT

3/8" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/4" x .035 5100 1/4" x .049 7500 1/4" x .065 10300 3/8" x .035 3300 3/8" x .049 4800 3/8" x .065 6550 Burst Pressure Rating >4x Working Pressure

$56.02 - $154.05

-

3/8" 37 Degree Female JIC Braided Stainless Steel Hose

3/8" 37° Female JIC Stainless Steel Braided PTFE Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 3/8" 37° Female JIC Swivel (9/16-18) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65° to 450°F Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 4"

$70.02 - $186.26

-

3/8" 37 Degree JIC Adapter for TRS21 Recovery Pump - Pair

Includes a Pair of Custom 3/8" 37 degree JIC fittings that adapt on to any TRS21 pump. (Does not include Pump) ***Note: This Adapter SHOULD NOT BE OVERTIGHTENED. Hand Tight with 1/4 Wrench turn will complete the face seal of the O-ring. (PTFE Thread Tape is NOT Required for this connection) ***Note: Always use 2 Wrenches while tightening the hose to the flare to stop the gasket from being crushed.

$22.41

-

3/8" BVV Compression End Caps

3/8" BVV Compression End Caps These End Caps come with a 3/8" Female Compression connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a 3/8" male tube stub connection to the lid. Specifications Material 304 Stainless Steel Connection Type: Tri-Clamp 3/8" Female Compression Connection Standard: 3A Sizes Available: 1.5" 2" 3" 4" 6"

$67.22 - $205.87

-

3/8" Clear Reinforced PVC Tubing 20 Foot Roll

3/8" Clear Reinforced PVC Tubing 20 Foot Roll Crystal clear Phthalate, BPA Free PVC compound, formulated with ingredients in compliance with applicable ratings: NSF-51 Certified USP Class VI Rated Compound, FDA Ingredients, Self-Extinguishing and Reinforced with braided polyester yarn. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Lightweight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 80A Phthalate Free! Common Applications: Food & beverage. Agriculture Drain Line Hose/Tubing Bundling Industrial Air and Water Hose Light Vacuum Liquid and Powder Transfer Medical and Pharmaceutical Sight Gauge Water Lines

$44.82

-

3/8" Fractional Tube Fitting Hose

3/8" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 3/8" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 4"

$71.42 - $175.06

-

3/8" Gum Rubber Tubing for Vacuum

3/8" Gum Rubber Tubing Pure gum rubber tubing is ideal for vacuum applications and will not collapse under a vacuum like other soft/low durometer tubing on the market. Please refer to this chemical compatibility chart: Cole-Parmer Chemical Compatibility - Natural Rubber Key Features: Tear Resistant Retains Memory Safely conducts many acids, chemicals, and gases Resistant to cold and hot temperature variations Very versatile Flexible and soft Developed especially for mechanical vacuum pumps Specifications Hardness Rating Soft Hardness Durometer 45A Material Gum Rubber ID 3/8" OD 7/8" Wall Thickness 1/4" Flexibility Very Flexible Temperature Range -70° to 180°F Maximum Vacuum 29 in. of Hg @ 72°F Compatible Tube Fittings Barbed Connections Color Beige

$93.83 - $945.33

-

3/8" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

SILCON® Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of SILCON tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make SILCON tubing an excellent choice for appliances and computers Peroxide-cured SILCON contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for SILCON as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. SILCON may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email Best Value Vacs to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$47.62 - $350.12

-

30 Ton Rosin Press V3

BVV™ 30 Ton Rosin Press V3 This is the new and improved BVV™ brand 30 Ton Rosin pro Rosin press. It features a pneumatically-driven hydraulic cylinder. The large 8 x 6 plates offer the most surface area for pressing and are made out of polished aluminum. This press also features 2 touchscreen PID controllers capable of keeping the heated plates within 1 degree of the set point. There is a manually operated timer with a built-in counter to keep track of usage. This press requires compressed air to function. Specification Dimensions 27”H, 21.5”W, 18”D Unit Weight 111 lbs. Electrical Requirements 120VAC / 60Hz / 15a max. Temperature Range Ambient – 480F (250C) Timer Range 1 – 999s Heating Power 1200W, 600W per plate Plate Size 8”W x 6”D Max. Plate Gap 1.15” Plate Material Polished Aluminum Air Requirements 120psi maximum Air Connection ¼” ARO (quick-connect fitting) Contains User Manual, Power Cable, Fuse

$1,785.62

-

30% Food Grade Distilled White Vinegar (Acetic Acid) - Non GMO

30% Distilled White Vinegar Food Grade - Kosher - Non GMO This is 300 grain White Distilled Vinegar. This vinegar is the result of the natural acetous fermentation of dilute ethyl alcohol from agricultural origin. The alcohol is converted to acetic acid by the microorganism Acetobacter aceti in vinegar generators or acetators. The product is prepared in accordance with the best commercial practice under strict sanitary conditions and the Federal guidelines for Good Manufacturing Practices. It is free of clarifiers, preservatives or other impurities and is Kosher certified. Ships in HDPE FDA Compliant Bottles. Chemical Formula: CH3COOH Molecular Weight: 60.05 g/mol CAS Registry Number: 64-19-7 Appearance Colorless Liquid Odor: Vinegar Density 1.01 to 1.04 (water = 1) Boiling Point: 215F @ 760 mm Hg and 100 grain Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H320, H315, H332, H402 GHS Precautionary Statements P261, P264, P280, P304+P340,P305+P351+P338, P273 UN Identification Number: 2790 Proper Shipping Name: Acetic Acid Solution Transport Hazard Class: 8 Packing Group: III DOT Placard: 30% Vinegar Food Grade - Certificate of Analysis (COA) 30% Vinegar Safety Data Sheet (SDS)

$25.21 - $1,274.44

-

300L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp Port and Locking Casters

300L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp/ Tri Clover Port and Locking Casters This massive 304 Stainless Steel Jacketed vessel can hold up to 300L of water (~80 gallons) and has a 12" Tri-Clamp port, (2) 1.5" Tri-Clamp ports, and (1) 1/2" FNPT port on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 43L or 11.5 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily. (Note: this unit comes bare and does not include any fittings besides the legs with casters.) Specifications Material 304 Stainless Steel Overall Dimensions 65" Tall x 30" Wide Pressure Rating 100 PSI MAX Connection Type(s): (1) 12" Tri-Clamp Top Port (2) 1.5" Tri-Clamp Top Ports (1) 6" Tri-Clamp Bottom Port (2) 1/2" FNPTOuter Jacket Ports ***Note: This item will ship via freight ONLY.

$5,251.83

-

300L 304SS Jacketed Collection and Storage Vessel with Locking Casters

300L 304SS Jacketed Collection and Storage Vessel with Locking Casters This massive 304 Stainless Steel Jacketed vessel can hold up to 300L of water (~80 gallons) and has a (3) 6" Tri-Clamp, (2) 1.5" Tri-Clamp/ Tri Clover and (1) 1/2" FNPT port on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 43L or 11.5 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily. (Note: this unit comes bare and does not include any fittings besides the legs with casters.) Specifications Material 304 Stainless Steel Pressure Rating 100 PSI MAX Connection Type(s): (3) 6" Tri-Clamp Top Ports (2) 1.5" Tri-Clamp Top Ports (1) 6" Tri-Clamp Bottom Port (2) 1/2" FNPT Outer Jacket Ports (1) 1/2" FNPT Top Port ***Note: This item will ship via freight ONLY.

$5,251.83

-

300L ASME Single Jacket Solvent Tank 350psi Max - Bare

300L ASME Single Jacket Solvent Tank 350psi Max - Bare This is a custom manufactured made ASME Certified 300L Jacketed Solvent Tank with ASME Stamp and made out of 304 Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold 300LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. This unit also has welded lift points on the top of the tank. **This Item will ship Via FREIGHT ONLY. Specifications Material 304 Stainless Steel Certification: ASME MAWP @ 100°C / 212°F: Inside 350 PSI / 2.42 MPa Jacket 150 PSI / 1.1 MPa MDMT -40°C / -40°F MIN TEMP -20°F at 350PSI Butane Capacity 300LBS Connection Sizes: (3) 6" Tri-Clamp (2) 2" Tri-Clamp (2) 1/2" FNPT Weight 750LBS Outer Dimensions: 64" Tall 32" W x 32" L

$15,405.36

-

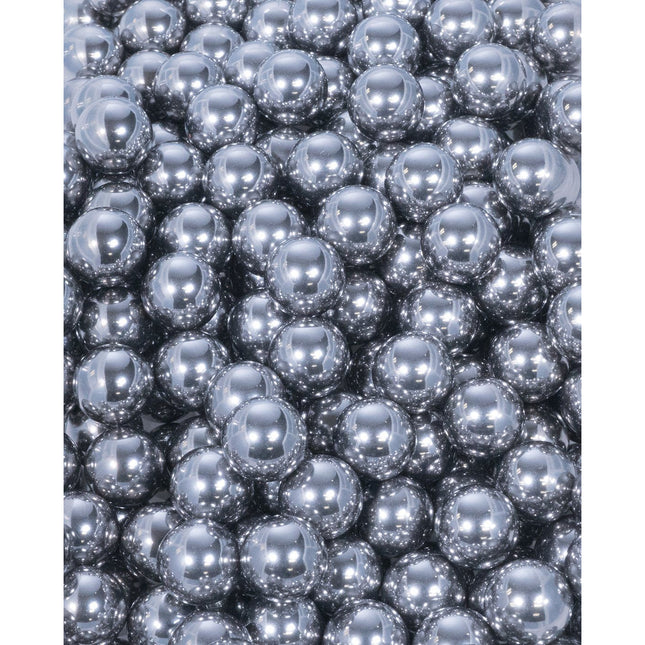

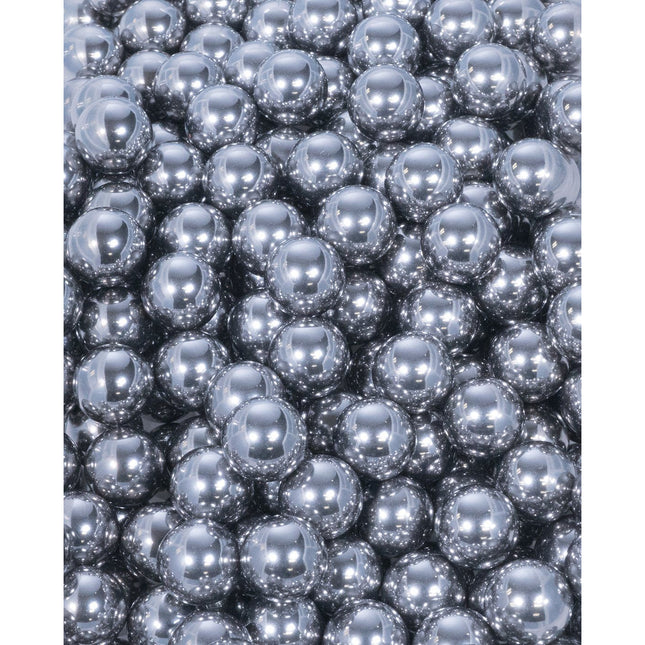

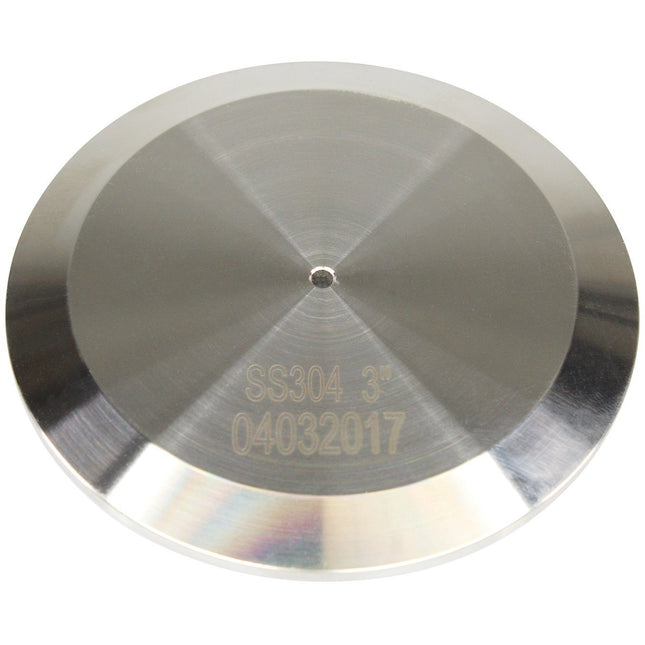

304 Stainless Steel Ball Bearings Packs

304 Stainless Steel Ball Bearings - Packs 304 Stainless Steel Ball Bearings are a great addition to aiding in filtration because they increase the surface area inside a system and allow fats and lipids to cling to them. After a run is complete, they are easily cleanable. These ball bearings come pre-packaged in 140-gram packets and may have a quantity +/- the stated quantity per pack. Sizes Available: 1/8" Diameter - ~1150 Ball Bearings Per Pack 1/4" Diameter - ~150 Ball Bearings Per Pack 7/16" Diameter - ~25 Ball Bearings Per Pack

$9.80 - $43.42

-

304 Stainless Steel Carboy

304 Stainless Steel Carboy This 304 stainless steel carboy is a very durable upgrade from plastic carboy's and allows it to be cleaned and sterilized much better. This unit comes with (2) 1/4" FNPT ports and (1) 6" Tri-Clamp top port and heavy-duty welded handles. For Storage and Vacuum Use Only Max Pressure 10 Psi ONLY (Note: This unit comes bare and does not include any fittings.)

$840.29 - $1,260.44

-

304 Stainless Steel Wool - 2 Pack

304 Stainless Steel Wool This 304 Grade Stainless Steel Wool is a great accessory for any extraction, condensing, or a filtration system. Stainless Steel Wool provides a vastly superior surface area compared to ball bearings and can be packed tighter to increase the surface area. This 304 Stainless Steel Wool comes in a pack of two rolls that roughly measure 15" x 15". BVV™ recommends cleaning this filtration material with high purity alcohol before use to reduce contaminants. Specifications Material 304 Stainless Steel Wire Thickness 0.006" Dimensions 15" x 15"

$28.01

-

316L Stainless Dutch Weave Sintered Filter Disk 1 micron and up - BUNA-N

316L Dutch Weave Sintered Filter Disk **Note: This product comes with Filter Disk and Gasket ONLY. Filter Plate and Spool are NOT included. Recommended Filter plate click here. These 316L stainless steel dutch weave filter disks come with a custom made gasket to allow the user to insert filtration between clamping ends of any Tri-Clamp interface. The interface fits so snug, its inherent design prevents any blow-by. BVV™ 316L Dutch Weave Sintered Filter Disk - Data Sheet Pressure Ratings w/o any backing support; strait pipe connection: 1.5" 200PSI 2" 200PSI 3" 200PSI 4" 200PSI 6" 50PSI 8" 10PSI *Supporting Back Plate Required P# FP800-V3 10" 10PSI *Supporting Back Plate Required P# FP1000-V3 12" 10PSI *Supporting Back Plate Required P# FP1200-V3

$42.01 - $812.28

-

316L Stainless Dutch Weave Sintered Filter Disk 1 micron and up - Silicone

316L Dutch Weave Sintered Filter Disk **Note: This product comes with Filter Disk and Gasket ONLY. Filter Plate and Spool are NOT included. Recommended Filter plate click here. These 316L stainless steel dutch weave filter disks come with a custom made gasket to allow the user to insert filtration between clamping ends of any Tri-Clamp interface. The interface fits so snug, its inherent design prevents any blow-by. Sintered Filter Disk Technical Data Sheet Pressure Ratings w/o any backing support; strait pipe connection: 1.5" 200PSI 2" 200PSI 3" 200PSI 4" 200PSI 6" 50PSI 8" 10PSI *Supporting Back Plate Required P# FP800-V3 10" 10PSI *Supporting Back Plate Required P# FP1000-V3 12" 10PSI *Supporting Back Plate Required P# FP1200-V3

$42.01 - $812.28

-

316SS FNPT Full Bore Ball Valve -40F to 450F

316SS FNPT Full Bore Ball Valve (Compare to Milwaukee 10 Series Ball Valves) This BVV™ 316 stainless steel full bore ball valve is a fire safe ball valve and is 1 piece ball valve construction. It also features a straight body style with Female NPT x Female NPT threaded connections with one side being pinned into place for zero movement during installation. The fire safe ball valve features a maximum pressure rating of 2000 PSI CWP and has a blowout proof stem made of 316SS and the temperature range of this ball valve is -40F° to 450F°. Standard: ASTM A351 Pressure Tested in compliance with API 598 Ninth Edition 2009: Sec.5 and Sec.6 Technical Data Sheet Valve Specifications Sizes Available: 1/4" FNPT 3/8" FNPT 1/2" FNPT Pressure Rating 2000 WOG Temperature Range -40 to 450F° Sizes Available: 1" (Fits 1.5" Tri-Clamp) Torque Specifications Do not Exceed 14.46ft-lbs when tightening.(Note: Overtightening the valve can cause damage to the pin. Doing this will void the valve warranty.) Valve Materials: Body 316SS / CF8M Ball 316 Stainless Steel Stem 316 Stainless Steel Stem Nut 304 Stainless Steel Insert 316 Stainless Steel Seat PTFE / Dyneon TFM1600 Thrust Washer PTFE / Dyneon TFM1600 Stem Packing PTFE / Dyneon TFM1600 Handle 304 Stainless Steel Handle Cov VINYL GRIP Handle Washer (1/2") 304 Stainless Steel Handle Nut 304 Stainless Steel Belleville Washer 304 Stainless Steel PIN 304 Stainless Steel

$92.43

-

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators This is a replacement clamp for 2L and 5L Eco Rotary Evaporator receiving flask.

$19.61

-

36 inch Filtration Funnel V2

Buchner Filtration Kit This filtration kit is operated by using a vacuum pump to pull the solution through the filter paper to remove particulate. The funnel has a 36" perforated plate to support the filter paper.

$10,643.70 - $11,455.98

-

36" Buchner Filtration Kit

Buchner Filtration Kit This filtration kit is operated by using a vacuum pump to pull the solution through the filter paper to remove particulate. The funnel has a 36" perforated plate to support the filter paper. The 150 liter collection vessel has multiple sight glass ports so that you can easily view inside the vessel as well as hold up a flashlight if needed. The standard lid includes a pressure gauge, KF-25 vacuum port, and a valve to release vacuum pressure or add positive pressure to the vessel. The vessel has a surrounding jacket that can be used to heat or cool the solution within the main vessel, it can even be outfitted with a mixer and recovery system if desired! To build your custom setup, talk to our experienced team of account representatives. This kit includes: 36" Filtration Funnel 150L Jacketed Reactor 1.5" Butyl hose Diaphragm vacuum pump (optional)

$13,304.63

-

37 Degree Female JIC X MNPT

BVV™ 37° Female JIC X MNPT BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are 37° JIC threads and NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) The 37° JIC connection will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. A FJIC X MNPT connector allows the user to cover either a Male JIC connection to a Male NPT connection or covert Female NPT threads to Female JIC connection. BVV™ FJIC x MNPT - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° FJIC (7/16-20) 3/8" 37° FJIC (9/16-18) 1/4"-18 MNPT 3/8"-18 MNPT Sizes Available: 1/4" FJIC x 1/4" MNPT 3/8" FJIC x 1/4" MNPT 3/8" FJIC x 3/8" MNPT

$9.80

-

37 Degree FJIC Cap

BVV™ - FJIC Cap BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by Best Value Vacs to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. Female JIC caps are designed for capping off male JIC threaded connections on extraction system BVV™ FJIC Cap - Data Sheet Specifications Material 304 Stainless Steel Sizes Available: 1/4" 3/8" 1/2"

$8.40

-

37 Degree FJIC Swivel Union

BVV™ 37° FJIC Swivel Union BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are 37° JIC threads and will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. Female JIC Swivel union allows users to attach Male JIC connectors or convert a MJIC connection to a female connection. Swivels are unique because they can be oriented to the direction the part needs to be facing. BVV™ FJIC Swivel Union - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° FJIC (7/16-20) 3/8" 37° FJIC (9/16-18) Sizes Available: 1/4" 3/8" x 1/4" 3/8"

$21.01

-

37 Degree MJIC Tee

BVV™ 37° MJIC Tee BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are 37° JIC threads and will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. A MJIC Tee allows the user to connect multiple JIC hoses to their system and use it as a splitter or any other type of extractor accessory with Female JIC ends. BVV™ 37° MJIC Tee - Data Sheet

$28.01 - $35.01

-

37 Degree MJIC Union

BVV™ 37° MJIC Union BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are 37° JIC threads and will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. A MJIC Union allows the user to connect multiple JIC hoses together to their system and use it as a splitter or any other type of extractor accessory with Female JIC ends. This MJIC Union also allows the user to attach different sized Female JIC connectors together. BVV™ 37° MJIC Union - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° MJIC (7/16-20) 3/8" 37° MJIC (9/16-18) Sizes Available: 1/4" 3/8" x 1/4" 3/8"

$7.00 - $9.80

-

37 Degree MJIC x FJIC

BVV™ MJIC x FJIC This unique 304 stainless steel fitting allows the user to adapt a 1/4" 37 Degree MJIC to a 3/8" 37 Degree MJIC or vise versa without having to replace or back out the fitting or taping the fitting. BVV™ MJIC x FJIC - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° FJIC X 3/8" 37° MJIC 3/8" 37° FJIC X 1/4" 37° MJIC

$8.40 - $9.80

-

37 Degree MJIC X FNPT

BVV™ 37° MJIC X FNPT BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are 37° JIC threads and NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. The 37° JIC connection will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. A MJIC X FNPT connector will convert and adapt Male NPT connection to a Male JIC connection or vise-versa. These MJIC x FNPT fittings are the industry standard for extraction systems and allow a multitude of configurations on any system. BVV™ MJIC x FNPT - Data Sheet

$7.00 - $21.01

-

37 Degree MJIC X MNPT

BVV™ 37° MJIC X MNPT BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These stainless steel tube fittings are 37° JIC threads and NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) The 37° JIC connection will create a seal by compressing the flared end against an opposite female/male flared connection. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by BVV™ to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. A MJIC X MNPT connector will convert and adapt a Female NPT connection to a Male JIC connection or vise-versa. These MJIC x MNPT stainless steel tube fittings are the industry standard for extraction systems and allow a multitude of configurations on any system. BVV™ MJIC x MNPT - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° MJIC (7/16-20) 3/8" 37° MJIC (9/16-18) 1/2" 37° MJIC (3/4-16) 3/4" 37° MJIC (1-1/16 - 12) 1" 37° MJIC (1-5/16 - 12) 1/4"-18 MNPT 3/8"-18 MNPT 1/2"-14 MNPT 3/4"-14 MNPT 1"-11-1/2 MNPT

$7.00 - $12.60

-

3CFM Single Stage Vacuum Pump

VE115 Single-Stage 3CFM Vacuum Pump This is the BVV™ Brand VE115 3CFM Single Stage Vacuum Pump. Single-stage vacuums pump exhaust into a chamber in the pump, which separates the oil from the pumped gas. Then, the oil is returned and the gas is exhausted. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$210.07

-

3mm Open Blast End Caps

3mm Open Blast End Caps These Tri-Clamp/ Tri Clover End Caps have a 3mm hole drilled in the center so most butane can tips to easily fit in the hole allowing the user to input solvent into a material column and open blast the material. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp 3mm Hole Standard: 3A Sizes Available: 1.5" 2" 3" 4"

$8.40 - $16.81

-

4 Way Vacuum Manifold

4 Way Vacuum Manifold The Vacuum Manifold can be used in conjunction with any vacuum application. It allows the user to selectively choose where to apply vacuum pressure. It is available in 1/4" or 3/8" barb connections and is assembled using 304-grade stainless steel parts. Please refer to the following example applications: Rotary evaporator vacuum distribution Multiple vacuum chambers with a single vacuum pump Air inlet to a vacuum system ***Note: Vacuum Manifold is intended for use with vacuum pressure only. It is not rated for positive pressure.***

$210.07

You have seen 240 out of 1081 products