Products

-

Neocision Spectra Explorer LED Grow Light

Neocision Spectra Explorer LED Grow Light Explorer Our Explorer grow light fixture is designed for a full grow cycle with maximized red for increased photosynthesis. Ideal for 2’ x 4’ tent environments for increased consistency and yield. Neocision Spectra Explorer Cutsheet Performance, Specs, Ranking FEATURES: Efficacy up to 2.56 Micromoles / J @120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.56 at 120VAC Photon Flux (µmol/s) (400-700nm): 870 Photon Flux Blue (µmol/s) (400-500nm): 161 Photon Flux Green (µmol/s) (500-600nm): 355 Photon Flux Red (µmol/s) (600-700nm): 355 Total Blue/Red - Energy Bands: 516 % Blue: 18.51% % Green: 40.76% % Red: 40.73% POWER Power Consumption: 340W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 2.90 A 208V: 1.75 A 240V: 1.51 A 277V: 1.31 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.7” x (W) 22” x (H) 4.1” Fixture Size (without driver): (L) 43.7” x (W) 22” x (H) 1.6” Power Supply Dimension: (L)18.7” X (W) 4.4” X (H) 2.4” Driver Net Weight: 6 lb. Fixture Net Weight: 6 lb. OTHER Mounting Height >6” above canopy Beam Angle 120 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Standard Power Cord (Extensions available) AWG 18, 6 Foot Standard Plug 120 VAC - NEMA 5-15P Substitute Plugs (Upon request at order for bulk purchases) 240 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070

$520.17 $291.30

-

Neocision Spectra Pro LED Grow Light - DLC Listed

Neocision Spectra Pro LED Grow Light PRO Neocision Spectra Pro fixtures feature 18.5% blue spectra and 40.7% red spectra with a peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Get increased yields, quality bud formation and high rates of cannabinoid production levels. Neocision Spectra Pro Cutsheet DLC Qualified Product List Performance, Specs and Ranking FEATURES: Efficacy up to 2.58 Micromoles / J @ 120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.58 at 120 VAC Photon Flux (µmol/s) (400-700nm): 1751 Photon Flux Blue (µmol/s) (400-500nm): 324 Photon Flux Green (µmol/s) (500-600nm): 714 Photon Flux Red (µmol/s) (600-700nm): 713 Total Blue/Red - Energy Bands: 1037 % Blue: 18.51% % Green: 40.76% % Red: 40.73% POWER Power Consumption: 680W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 5.72 A 208V: 3.44 A 240V: 2.98 A 277V: 2.58 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 43.9” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 43.9” x (H) 1.6” Power Supply Dimension: (L)23” X (W) 6.5” X (H) 3” Driver Net Weight: 10.1 lb. Fixture Net Weight: 13.8 lb. OTHER Mounting Height >6” above canopy Beam Angle 110 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Power Cord Length (Extensions available) AWG 16, 6 Foot Standard Plug 120 VAC - NEMA 5-15P Substitute Plugs (Upon request at order for bulk purchases) 240 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed. 4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$762.92 $540.98

-

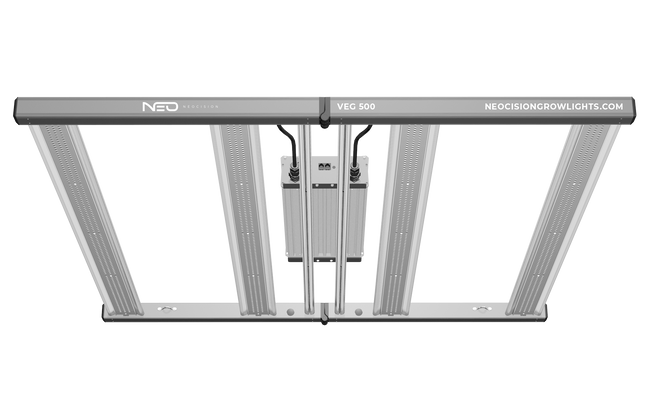

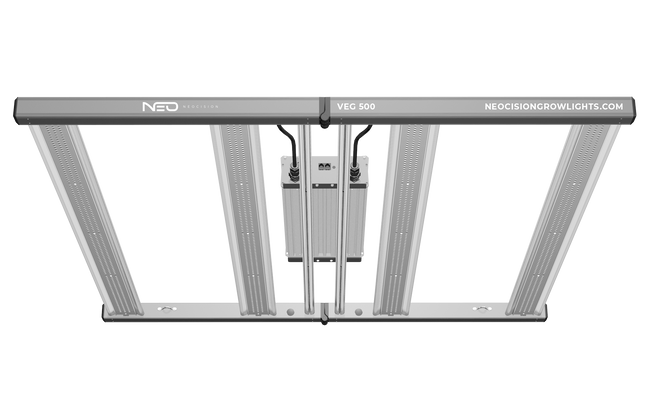

Neocision Spectra Veg 500W LED Grow Light

Neocision Veg 500 LED Grow Light Neocision Veg 500 LED grow light fixtures are designed for commercial growers seeking enhanced yield and canopy coverage as compared to 600W metal halide or 630W ceramic metal halide lights. Increasing PPFD can help you accelerate growth for your mother plants before and after you take cuttings. Features: Tested efficacy of 2.62 μmols/J at 240 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation 5 Year Limited Warranty

$316.27

-

Neocision Spectra Veg LED Grow Light - DLC Listed

Neocision Spectra Veg LED Grow Light VEGETATIVE Our Vegetative Spectrum 5000k grow light fixture is designed to produce a healthy and more flavorful, aromatic yield. Experience a new level of cultivation. Neocision Spectra Veg Cutsheet DLC Qualified Product List Performance, Specs, Ranking FEATURES: Efficacy up to 2.51 Micromoles / J @120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value-adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.5~2.60 at 120VAC - 240VAC Photon Flux (µmol/s) (400-700nm): 853 Photon Flux Blue (µmol/s) (400-500nm): 221 Photon Flux Green (µmol/s) (500-600nm): 390 Photon Flux Red (µmol/s) (600-700nm): 242 Total Blue/Red - Energy Bands: 463 % Blue: 25.94% % Green: 45.70% % Red: 28.53% POWER Power Consumption: 340W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 2.90 A 208V: 1.75 A 240V: 1.51 A 277V: 1.31 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 22” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 22” x (H) 1.6” Power Supply Dimension: (L)16.9” X (W) 6.5” X (H) 3” Driver Net Weight: 6 lb. Fixture Net Weight: 6 lb. OTHER Mounting Height >6” above canopy Beam Angle 110 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Standard Power Cord (Extensions available) AWG 18, 6 Foot Standard Plug 240 VAC - NEMA 6-15P Substitute Plugs (Upon request at order) 120 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$450.82 $282.97

-

Neocision Vacuum Oven Shelves

Neocision Vacuum Oven Shelves These are stainless steel oven shelves for our Neocision Vacuum Ovens and fit either a 0.9CF or a 1.9CF Neocision Oven. Specifications: 0.9CF - 11" (279mm) x 11.2" (285mm) x 1/8" Thickness 1.9CF - 14" (356mm) x 15.75" (400mm) x 1/8" Thickness

$48.55 - $62.42

-

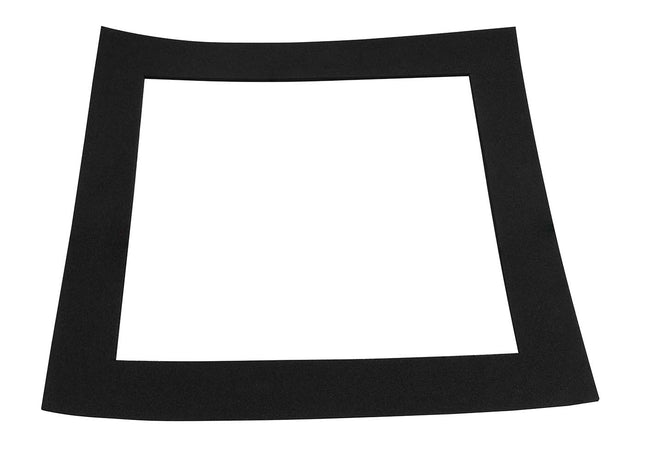

Neoprene Gasket for Cubes

NEOPRENE GASKET FOR CUBES Replacement Neoprene gasket for acrylic vacuum chambers. The existing gasket will have to be completely removed in order to get the new one to seal. It is recommended to use a cleaning solution such as CitraKlean.

$54.10

-

Neutral Activated Alumina Chromatographic Grade (50-200um) *Compare to Alumicel™N

Neutral Activated Alumina pH: 6.8 | 50-200 Micron Made in USA *Compare to Alumicel™ N This activated alumina is a neutral pH adsorbent used to remove excess moisture from your extraction and CRC process. The addition of this media is used as the last layer in the typical BVV™ CRC setups. This grabs any excess moisture from the previous CRC layers and the Biomass. The activated alumina will produce a sugary finish almost immediately after you start your purge. This rapid crystallization is because the process has stripped out additional phospholipoids and fats. This produces an overall extract that is less prone to oxidation and has a longer shelf life. Chromatographic Grade Manufactured in the USA since 1937 Manufactured to the highest quality standards ISO 9001:2015 BVV™ Neutral Activated Alumina Technical Data Sheet BVV™ Neutral Activated Alumina Safety Data Sheet BVV™ Neutral Activated Alumina Quality Certificate

$74.90 - $13,177.73

-

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting allows the user to adapt a male NPT thread to a 1/4" Hose barb for flexible tubing. Note: This connection requires PTFE tape on the threaded side to create a leak free seal.

$4.85

-

Nitric Acid 64.6% Lab Grade

Nitric Acid 64.6% Laboratory / Technical Grade *Excellent for gold refining Nitric Acid 64.6% (41° Baumé) (HNO3) is a highly corrosive mineral acid widely used in various industrial application. It is a clear to pale yellow in color and is a strong oxidizing agent known for its corrosive properties. It is commonly used in chemical manufacturing, metal processing, and as a laboratory reagent. Nitric Acid plays a key role in refining gold, particularly in methods like aqua regia refining and in parting processes. Urban mining and pcb board gold recovery commonly uses nitric acid to dissolve gold. *Ships in Level 4 Fluorinated Polyethylene Bottles, 55g ships in HDPE blue drum. Aqua Regia Gold Refining Process (Most Common Use)Aqua regia is a mixture of nitric acid (HNO₃) and hydrochloric acid (HCl) in a 1:3 ratio. This combination dissolves gold, which neither acid can do alone. Step-by-step Overview:Preparation of Aqua Regia: Mix 1 part nitric acid with 3 parts hydrochloric acid. Dissolution: Add impure gold to the aqua regia. Nitric acid oxidizes the gold to gold ions (Au³⁺). Hydrochloric acid provides chloride ions (Cl⁻) to form chloroauric acid (HAuCl₄), which is soluble. Filtration: Filter the solution to remove impurities and undissolved metals. Precipitation: Add a reducing agent like sodium metabisulfite (Na₂S₂O₅) to the solution. This causes pure gold to precipitate out of solution as fine particles. Washing & Melting: Wash the gold powder, dry it, and melt it to form pure gold bars or granules. Chemical Formula: HNO3 Molecular Weight: 63.013 CAS Registry Number: 7697-37-2 Appearance Colorless to faint yellow Odor: Acrid Density > 1.4078@ 25 °C Boiling Point: 248 'F 67.2% HNO3 Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H314, H330 GHS Precautionary Statements P210, P220, P260, P264, P271, P280, P284, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P316, P320, P321, P363, P370+P378, P403+P233, P405, and P501 UN Identification Number: 2031 Proper Shipping Name: Nitric Acid Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard: Nitric Acid 64% Lab/Tech Grade Safety Data Sheet (SDS) Nitric Acid 64% Lab/Tech Grade Certificate of Analysis (COA)

$38.84 - $1,179.06

-

Nitrogen Hydrogen 95% N2 and 5% H

Nitrogen Hydrogen 95% N2 and 5% H 99.5% Purity, Filled, Compressed Gas Made in Italy This 3"x12" compressed gas tank is filled with a high purity blend of nitrogen and hydrogen. 95% Nitrogen and 5% Hydrogen. The gas can be removed using our regulator or valve dispenser that attaches to the top of the tank. This tank will produce a continuous ~56 Seconds of Nitrogen Hydrogen @ 80PSI. *Note Tank Pressure is 1624 PSI *At end of use, completely empty the tank for recycling. Tank Volume of Gas Product SKU: 130g / 103 Liters / 27 Gallons NITROHYDRO-130G Regulator/Dispenser Details (not included with tank only purchase) Regulator - Adjustable via. needle valve, regulated to 29 PSI. Made in Italy. Thread: M11x1 (tank connection). Output: 1/4" JIC to connect to any of our 1/4" extractor hoses or vacuum hoses. Gauges read in BAR. M11 Valve Dispenser Kit - Includes adjustable pushpin style valve dispenser. Output: 1/4" JIC Flare, NO GAUGE. Connects to any 1/4" JIC Hose.

$52.71 - $215.01

-

Nitrogen Pressure Filter

Nitrogen Pressure Filter Is vacuum filtration bottlenecking your processing? Filter faster with BVV's Nitrogen assisted pressure filters. Designed for versatility our prebuilt pressure filters come complete with our 1 micron Dutch Weave Sintered disk for ultra-fine filtration. Process continuous or batch-style solutions in half the time compared to most vacuum filtration applications. Specifications 6"x12" or 12"x12" filtration body 1um Dutch Weave Sintered disc Filter Plate Retention Ring Fast Flow Filter paper Included Solvent dispersal plate 2X Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves 1X JIC Drain Valve (6NPS: 1/4" 12NPS: 1/2" JIC) Maximum Pressure Rating: 125PSI

$2,219.41 - $4,092.03

-

Nitrogen Tank for Extraction 99.5% Pure

Nitrogen Beverage Grade 99.5% Pure Made in Italy This modest but mighty nitrogen tank is a great to pair with any 2lb or smaller extraction system. For those customers that need nitrogen to push their solvent through color remediation columns (CRC) or for those super cold dewax extractions that need the extra push to get the remaining solvent out of the cold columns. This tank will produce a continuous ~66.5 Seconds of Nitrogen @ 80PSI. Directions: (*Hose not Included with regulator) Connect a stainless steel braided 1/4" JIC hose (or vacuum hose BVV-HVAC) to your extractor, placed at the valve where you need your extra pressure push. Using the needle valve you can open the regulator and the nitrogen will flow. Pressurize 15-30PSI. *Note Nitrogen Tank Pressure is 1580 PSI *At end of use, completely empty the tank for recycling. Tank Volume of Nitrogen Coverage Product Sku: 130g / 103 Liters / 3.67 Cubic Feet See Use Chart Below... NITROGEN-130G Regulator/Dispenser Details (not included with tank only purchase) Nitrogen Regulator - Adjustable via. needle valve, regulated to 80 PSI. Made in Italy. Thread: M11x1 (tank connection). Output: 1/4" JIC to connect to any of our 1/4" extractor hoses or vacuum hoses. Gauges read in BAR. M11 Valve Dispenser Kit - Includes adjustable pushpin style valve dispenser. Output: 1/4" JIC Flare, NO GAUGE. Connects to any 1/4" JIC Hose. How long will it last?: A 1lb column of biomass (3"x24") is equal to ~2.7 liters empty. That's about 38 column volumes. Assuming you only used 4 column volumes per extraction you would get ~10 extractions from one tank. Column Size Column Volume # Runs/Tank 1.5x12 (70g biomass column) 0.34 Liters ~75 2x12 (120g biomass column) 0.6 Liters ~54 3x24 (1lb biomass column) 2.7 Liters ~12 4x24 (2lb biomass column) 4.9 Liters ~6 *Use calculated @ 4 column volumes per run What Is Nitrogen Gas? Nitrogen gas is a chemical element and a diatomic molecule with the chemical formula N2. It is a colorless, odorless, and tasteless gas that makes up about 78% of Earth's atmosphere by volume. Nitrogen gas is an essential component of the air we breathe and plays a crucial role in various natural processes and industrial applications. In its gaseous form, nitrogen is composed of two nitrogen atoms tightly bonded together by a strong triple bond. Due to its stable molecular structure, nitrogen gas is relatively inert and does not readily react with other substances under normal conditions. What Is Nitrogen Gas Used For? Nitrogen gas has a wide range of applications across various industries and scientific fields due to its inert nature, abundance, and unique properties. Some of the key uses of nitrogen gas include: Food Preservation: Nitrogen gas is used to create controlled atmospheres in food packaging to extend the shelf life of perishable products. It helps prevent the growth of spoilage microorganisms and maintains the freshness of packaged foods. Laboratory Applications: Nitrogen gas is used in laboratories as a carrier gas for chromatography, as a purge gas to remove oxygen and moisture from sensitive reactions, and for preserving and storing samples. Welding and Metalworking: Nitrogen gas is employed as a shield gas during welding and metalworking processes to prevent oxidation and maintain the integrity of metal surfaces. Electronics Manufacturing: In electronics manufacturing, nitrogen gas is used to create inert environments that prevent oxidation and improve the quality of soldering and component assembly. Cryogenic Applications: Nitrogen gas, when cooled to extremely low temperatures, becomes liquid nitrogen. It is used in cryopreservation of biological samples, freezing and storing biological materials, and in various cryogenic cooling applications. Fire Suppression: Nitrogen gas is utilized as a fire suppressant in certain situations to reduce the concentration of oxygen, effectively suppressing fires and preventing explosions. Oil and Gas Industry: In the oil and gas industry, nitrogen gas is used for pressure testing pipelines, purging equipment, and enhancing oil recovery. Medical and Healthcare: Nitrogen gas is used in medical applications, such as cryotherapy for skin treatments, freezing of warts and lesions, and providing a dry environment for sensitive medical instruments. tAerospace and Aviation: Nitrogen gas is used to pressurize aircraft tires and hydraulic systems, preventing moisture and oxidation-related issues. Fertilizer Production: Nitrogen gas is a key component in the production of ammonia-based fertilizers, which are essential for promoting plant growth in agriculture. Diving Industry: In underwater diving, nitrogen gas is used in breathing gases such as air and nitrox. Pneumatic Systems: Nitrogen gas is used in pneumatic systems for inflating tires, powering tools, and operating machinery. Food and Beverage Industry: Nitrogen gas is used to dispense draft beer, wine, coffee, and other beverages, creating a foamy head and enhancing the presentation. How Can I Pressure Test My Extractor With Nitrogen? Pressure testing your extractor with nitrogen involves using nitrogen gas to check for leaks, verify the integrity of the equipment, and ensure its safety before performing actual extraction processes. Here's a step-by-step guide on how to pressure test your extractor using nitrogen gas: Materials Needed: Nitrogen gas cylinder with appropriate regulator Pressure gauge PTFE tape (thread seal tape) Bubble solution or soapy water Safety goggles and gloves Wrench or spanner Steps: Preparation: Ensure that the extractor is clean and free from any residual materials. Check all fittings, connections, valves, and joints for signs of damage, wear, or corrosion. Replace any damaged components. Make sure the extractor is properly assembled and closed, including any access ports or lids. Safety Precautions: Wear appropriate safety goggles and gloves to protect your eyes and hands. Work in a well-ventilated area to prevent the buildup of nitrogen gas. Regulator Setup: Attach the nitrogen gas cylinder to the regulator and secure it tightly using a wrench. Set the desired pressure on the regulator according to the recommended pressure for your extractor and testing requirements. Sealing Threads: Apply PTFE tape to the threads of the fittings and connections. This helps create a better seal and prevents leaks. Connect Nitrogen Gas: Connect the regulator outlet to the appropriate inlet or access port on the extractor using a compatible hose or tubing. Pressure Testing: Slowly open the nitrogen gas cylinder valve to allow gas to flow into the extractor. Monitor the pressure gauge and allow the pressure to build up to the desired test pressure. Once the desired pressure is reached, close the cylinder valve to stop the flow of nitrogen gas. Leak Detection: If pressure is not maintained apply a bubble solution or soapy water to all the fittings, joints, and connections. Inspect the extractor for any bubbles forming, indicating potential leaks. Pay close attention to areas where bubbles appear, and tighten or adjust fittings after depressurizing the system as needed to eliminate leaks. Release Pressure: Slowly release the pressure from the extractor by gradually opening the cylinder valve. Once the pressure is completely released, disconnect the nitrogen gas source. Final Inspection: Reapply the bubble solution or soapy water to the connections that were adjusted. Verify that no bubbles form, indicating that leaks have been successfully resolved. Documentation: Keep a record of the pressure test results, including the test pressure and any adjustments made. Repeat if Necessary: If any leaks were detected and resolved, repeat the pressure test to ensure all leaks have been eliminated. Pressure testing your extractor with nitrogen gas helps ensure the safety and integrity of the equipment, minimizing the risk of leaks during actual extraction processes. Always follow proper safety guidelines and manufacturer recommendations when working with nitrogen gas and pressure testing equipment. How Do I Perform A Nitrogen Assisted Extraction? Using nitrogen to inject butane into a closed-loop extraction system requires careful consideration and adherence to safety protocols. Nitrogen gas can be used to pressure test the extraction system, assist in transferring butane throughout the system, and assist in the process of adsorbent filtration/color remediation. Here's a step-by-step guide on how to use nitrogen to inject butane into your closed-loop extraction setup: Materials Needed: Closed-loop extraction system with Pressure Relief Valve Nitrogen gas cylinder with appropriate regulator Pressure gauge Nitrogen-compatible hose or tubing Butane tank Butane-compatible hose or tubing Safety goggles and gloves Wrench or spanner Steps: Safety Precautions: Wear appropriate safety goggles and gloves to protect your eyes and hands. Work in a C1D1 environment to prevent the buildup of flammable gases. Preparation: Ensure that the closed-loop extraction system is clean, properly assembled, and free from any residual materials. Regulator Setup: Attach the nitrogen gas cylinder to the regulator and secure it tightly using a wrench. Set the desired pressure on the regulator based on the recommended pressure for your closed-loop system and extraction process We recommend utilizing 25-50 PSI to perform solvent transfer throughout the system. Nitrogen Line Connection: Connect the regulator outlet to the nitrogen-compatible hose or tubing. Connect the other end of the hose to the vapor port or accessory port to the recovery cylinder of your closed-loop system. Butane Line Connection: Connect the recovery cylinder to the closed-loop system using a butane-compatible hose or tubing. Ensure that the recovery cylinder is securely connected to the system, properly sealed, and grounded. Pressurizing the System: Slowly open the nitrogen gas cylinder valve to allow nitrogen gas to flow into pressurize the recovery cylinder. Monitor the pressure gauge and pressurize the recovery cylinder to the desired pressure for injecting butane. Nitrogen gas is used to create pressure that forces the butane into the system. Injecting Butane: Open the valve on the recovery tank to allow the butane to flow into the material column of the closed-loop system. The pressurized nitrogen gas assists in transferring the butane through the system and into the collection base of the system. Monitoring and Safety: Carefully monitor the pressure levels on both the nitrogen gas cylinder and the recovery cylinder. Venting: Once the injection and extraction processes are complete, close the valves on both the nitrogen gas cylinder and the recovery tank. Prior to applying heat to your collection base and starting your solvent recovery procedure first slowly vent the nitrogen from the collection base directly into the ventilation system of your C1D1 Booth. Monitor the pressure gauge and sight glass of the collection base closely. Slowly and incrementally vent the nitrogen from the system until the solution begins to boil this is an indication that the nitrogen filling the headspace of the collection base has been removed and the butane is filling the remaining headspace. Additionally, if the pressure starts to increase after an incremental venting procedure that is a good indication that the nitrogen has been released from the system and the butane is building pressure within the system. If the tank PSI remains the same after a venting procedure then nitrogen is most likely still within the system. Recovery: Once the nitrogen has been successfully removed from the collection base proceed to vent the nitrogen from the empty recovery cylinder and pull the recovery cylinder and the associated lines under vacuum. With the nitrogen now removed from both the collection base and recovery cylinder you can now proceed with your recovery procedure Disconnect the nitrogen gas line and the butane line from the closed-loop system. Properly store the nitrogen gas cylinder and the recovery tank according to safety guidelines. Using nitrogen to inject butane into a closed-loop extraction system requires a solid understanding of the equipment, processes, and safety procedures involved. Always refer to your closed-loop system's manufacturer guidelines and follow best practices for safe operation. How Much Nitrogen Pressure Do I Need For Adsorbent Filtration/ Color Remediation? The nitrogen pressure required for adsorbent filtration and color remediation can vary depending on the specific equipment, setup, and the type of media you are using. It's essential to follow the manufacturer's recommendations for your particular closed-loop extraction system and adsorbent filtration equipment. In general, nitrogen gas can be used to apply pressure to assist in pushing the solvent through the adsorbent media, enhancing the filtration and color remediation process. The pressure you need may vary based on factors such as the viscosity of the solvent, the flow rate, the type of adsorbent media, and the desired results. It's recommended to start with a moderate nitrogen pressure and gradually increase it while monitoring the flow rate and effectiveness of the process. Generally, pressures in the range of 20 to 50 psi (pounds per square inch) are commonly used for adsorbent filtration and color remediation. However, this pressure range can be adjusted based on your specific equipment and requirements. Keep in mind that using too high of a pressure can potentially cause channeling, uneven flow, and limited retention through the adsorbent media, affecting the quality of the filtration process. It's essential to strike a balance between achieving effective filtration and avoiding excessive pressure that could lead to inefficient results or potential safety risks. It's best to perform small-scale tests before scaling up to ensure optimal results and start off slowly when using nitrogen pressure for adsorbent filtration and color remediation. Chemical Formula: N2 Molecular Weight: 28.014 g/mol CAS Registry Number: 7727-37-9 Appearance Colorless Odor: Odorless Density 0.072 lb/ft3 Boiling Point: -196C (-320.8F) Solubility in water: N/A GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H280, H281 GHS Precautionary Statements P282, P336+P317, P403, and P410+P403 UN Identification Number: 1066 Proper Shipping Name: Nitrogen, Compressed Transport Hazard Class: 2.2 Packing Group: None DOT Placard: Nitrogen Safety Data Sheet (SDS)

$56.87 - $219.17

-

Nitrous Oxide Tank Pressure Regulator made by Best Whip

Nitrous Oxide Tank Regulator for Whip Cream Dispensers This specifically designed quick charge adapter makes connecting and disconnecting your dispenser to the regulator quick and easy. Start infusing today using this regulator to connect to your 635g N2O charger. Nitrous tanks with an M11 fitting with connect to this regulator. M11 fitting (connects to tank) Whip Cream Adapter Fitting M22x2.0 (fits whip cream dispenser) Quick Disconnect Hose (self-sealing when removed) The Best Whip N2O regulator requires specific working pressure levels depending on your recipe and the desired texture and intensity. The result is perfect consistency across different recipes with just the right amount of gas. Fats, proteins, and ingredients / flavorings are the key factors when determining the required pressure for your recipe. Nitrous Oxide Foam Pressure Table: Recipe Type and Foam Density Level Dispenser Contents Recommended Pressure (Bar) Light foam (airy whipped cream) 300-450ml 6-9 Thick foam (cold foam) 300-450ml 9-11 Cocktail foam 200-400ml 8-11 Liquid foam (sauces and soup) 300-450ml 5-7 Firm foam (deserts i.e., cakes, merengue) 200-250ml 15-16 Cocktails and Infusion Table: Intensity Level Dispenser Contents Recommended Pressure (Bar) Recommended Infusion Time Low 10-150ml 5-7 15 minutes Medium 150-250ml 7-16 30 minutes High 250-500ml 8-17 2 Hours

$81.84

-

Non-Mercury Glass Thermometer with 10/30 Joint

Non-Mercury Glass Thermometer with 10/30 Joint This non-mercury glass thermometer has a 10/30 ground glass joint and is 14" long with a temperature range of -10°C to 250°C with 1 degree increments. This thermometer is made in Germany and is Serialized and Calibrated. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$2,510.70

-

NPT Stainless Steel Thermowell

NPT Stainless Steel Thermowell These stainless steel thermowells are the perfect addition to an extraction system allowing the user to probe the internal temperate of a system component to know what temperature it is at. This thermowell feature 304 stainless steel and is 2.5" to 6" long with a 1/4" - 1/2" Male NPT threaded connect and a 1/4"-1/2" female NPT threaded connection on the top of the hex head.

$48.55 - $62.42

-

NRE 10L 20L 50L Check Valve Gasket

Check valve to be placed between the condenser and receiving flask on BVV rotary evaporators. The outer diameter of the joint is 60mm.

$83.23

-

NRE 5L Evaporating Flask Gasket Set

NRE 5L Evaporating Flask Gasket Set This two part sealing kit will only fit the evaporating flask for the 5L Neocision rotary evaporator.

$201.13

-

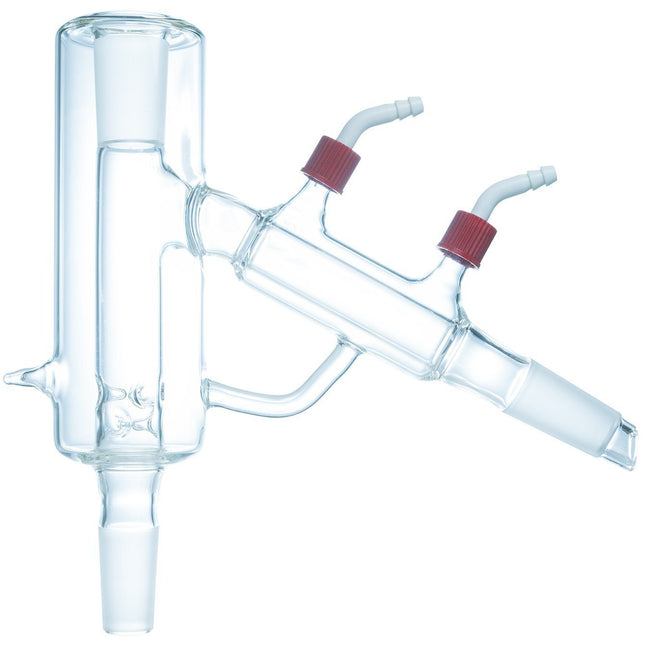

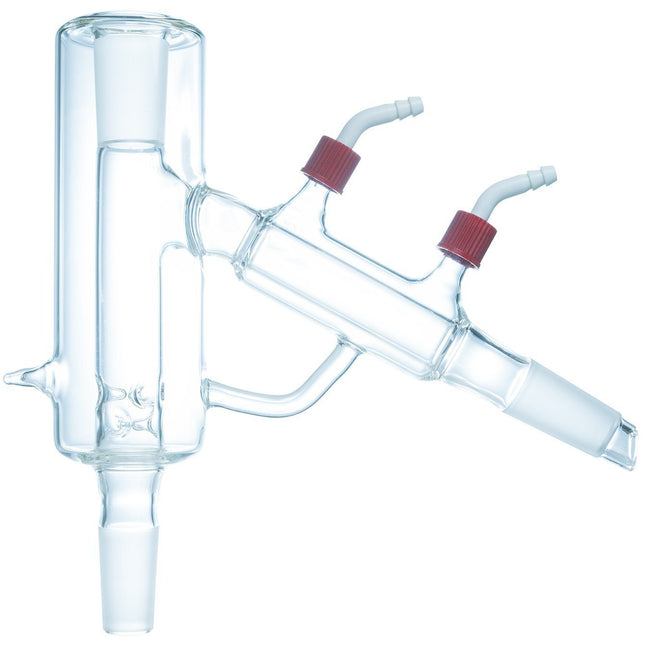

NRE 5L Main Condenser

NRE 5L Main Condenser This condenser directly connects to our 5L Neocision ETL Lab Certified Rotary Evaporator (SKU: NRE-5L). NOTE: Condenser does not come with GL caps and barbs or gaskets. Specifications Connection Type and Size To Bump Trap Flange ID32/OD50 (mm) To Collection Flask Flange ID22/OD37.5 (mm) Condenser Input/Output GL14 Vacuum GL14

$610.34

-

Nylon Filter Bag Socks

Nylon Filter Bag Socks Nylon Filter Bag Socks make loading and unloading spools way faster and easier. Keep production costs down by hot-swapping socks and continuing to process material with less downtime. The 90 micron socks are made of nylon and the 53 micron socks are made of monofilament polyester, both of which won't react to solvents and are very durable. For the 90 micron socks, we recommend getting socks that are 2" larger in diameter than the spool size, which is how we've sized them. **NOTICE** Unlike the 53 micron socks, the 90 micron socks do not feature extra material around the top collar which can stretch around the top of the column, they will only fit inside the column. The only exception to this is the FILTERBAG-10X60IN-90M. ** Quality Materials: The 90 micron bags are made of high quality Nylon, and the 53 micron Filter bags are made of monofilament polyester, both of which are durable, stable, rust and corrosive resistance and good for long time use. Precise Design: The filter bag is designed to fit Spool. Wide Range of Applications: The filter bag is used to filter impurities during the reaction process is suitable for different media with working highest Temperature at 248℉. Resistant to many chemicals, unaffected by metal fatigue or corrosion, and have high tensile strength. Convenient organization and storage: 1PC Packed in a small plastic bag. The filter bag life depends on the working environment and the frequency of using, Check it Regularly for aging, damaged or hardening. SKU BAG SIZE (in) FITS SPOOL(in) (90m will not stretch over top of column) MESH (micron) FILTERBAG-6X60IN-90M 6X60 4 90 FILTERBAG-8X60IN-90M 8X60 6 90 FILTERBAG-10X60IN-90M 10x60 8 90 FILTERBAG-12X36IN-90M 12x36 10 90 FILTERBAG-12X60IN-90M 12x60 10 90 FILTERBAG-12X60IN-90M 12X60 8 90 FILTERBAG-3IDx12L-53M 5x14 3x12 53 FILTERBAG-4IDx24L-53M 8x28 4x24 53 FILTERBAG-4IDx48L-53M 8x52 4x48 53 FILTERBAG-6IDx24L-53M 10x30 6x24 53 FILTERBAG-6IDx48L-53M 10x54 6x48 53 FILTERBAG-8IDx48L-53M 14x56 8x48 53 Chemically Compatible with: Acetone Amyl Alcohol (only up to 70°F) Butane Butyl Alcohol Diacetone Alcohol (only up to 70°F) Dowtherm (only up to 70°F) Ethanol Ether Ethyl Acetate Ethylene Glycol Glycol Glycol Monoether (only up to 70°F) Isopropyl Acete Isopropyl Alcohol Methane (only up to 70°F) Methyl Acetate Methyl Alcohol Methyl Cellosolve (only up to 70°F) Methylene Chloride (only up to 100°F) Nitrogen Propane (only up to 250°F) Propylene Glycol Sodium Carbonate Sodium Chlorate (only up to 180°F) Sodium Chloride 10% Sodium Cyanide Sodium Peroxide (only up to 70°F) Steam (only up to 220°F) Sulfuric Acid 5% Sulfuric Acid 50% (only up to 70°F) Sulfuric Acid 96% (only up to 70°F) Sulfuric Acid Fuming Sulfurous Acid

$26.36 - $55.49

-

Nylon Filter Bag Socks with Spool Collar (Fits Extractor Spools)

BVV Nylon Filter Bag Socks with Spool Collar (Fits Extractor Spools) Nylon Filter Bag Socks Filter socks make loading and unloading spools way faster and easier. Keep production costs down by hot-swapping socks and continuing to process material with less downtime. The 100 micron socks are made of nylon and the 53 micron socks are made of monofilament polyester, both of which won't react to solvents and are very durable. The BVV Filter Bag Fitment Our bags are designed to nearly match the internal circumference. Our bags will make contact smoothly with the wall of the spool allowing them fit without wrinkling or bunching. The added collar will fit over any end ferrule on the spool. The collar makes loading easier. Our filter bags are also lengthened to accommodate the complete fill of the column you are loading, maximizing space used! We have filled and tested each sock we offer, and made necessary adjustments to make sure these perform and hold up to repeated use. *(~Denotes Approximation) Each bag is laser cut but hand stitched and will have some small deviations in dimension. Filter Bag ~Actual Size 1.5"x12" 1.96x16 1.5"x24" 1.96x28 1.5"x36" 1.96x40 2"x12" 2.95x16 2"x24" 2.95x28 2"x36" 2.95x40 3"x24" 4.75x28 3"x36" 4.75x40 4"x24" 6.75x28 4"x36" 6.75x40 4"x48" 6.75x52 6"x36" 9.75x40 6"x48" 9.75x52 6"x60" 9.75x65 8"x36" 12.75x40 8"x48" 12.75x52 8"x60" 12.75x65 10"x36" 15.75x40 10"x48" 15.75x52 10"x60" 15.75x65 12"x36" 18.5x40 12"x48" 18.5x52 12"x60" 18.5x65

$18.73 - $58.26

-

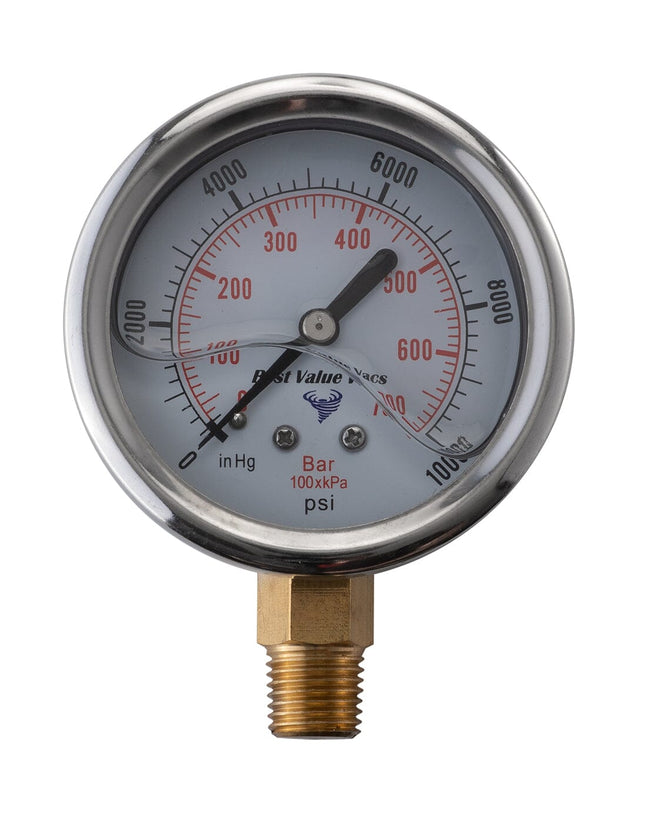

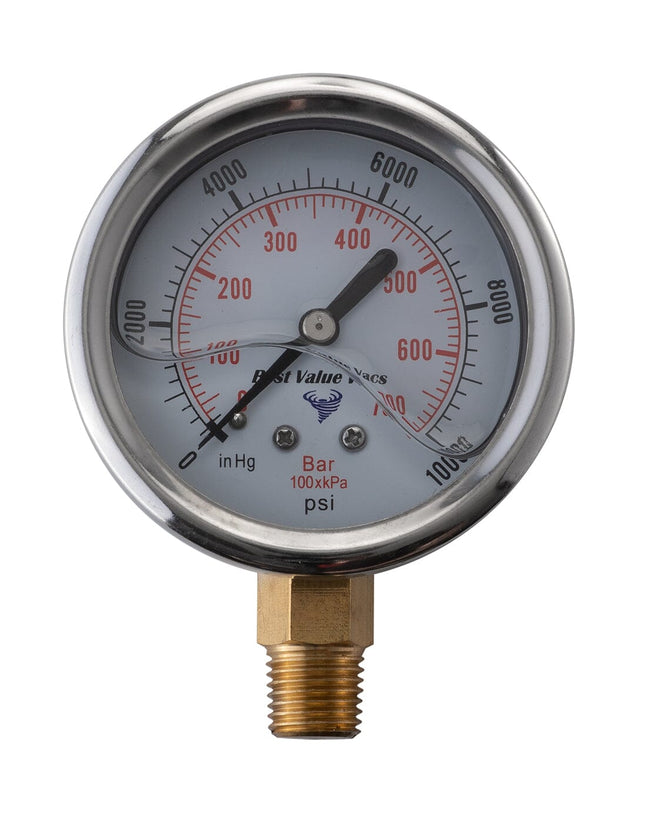

Oil Filled Vacuum/Pressure Gauge - Bottom Mount - 1/4" MNPT

Oil Filled Vacuum/Pressure Gauge The Oil Filled Vacuum/Pressure Gauges have internal parts that are permanently lubricated to assist in smooth movement and fine tuning of the needle. All models are bottom mount with a 1/4" MNPT brass connection. All positive pressure is measured in both PSI and Bar. Negative pressure is measured in inHg and Bar. BVV™ Gauge - TDS

$20.81 $13.87

-

Order Protection Order Protection

OrderProtection.com is offered as an additional item at checkout. There’s no extra application process or forms to fill out, customers just checkout and are instantly protected against items: Stolen Delivered Not Received Damaged Item Lost in Transit Wrong Item

$1.36 - $277.43

-

Oxone Monopersulfate Compound REDI-DRI® free flowing

Oxone Monopersulfate Compound REDI-DRI® is a potassium triple salt mainly used as a stable, easy to handle and nontoxic oxidant. REDI-DRI® is a process that allows the salts to be a free flowing material for months of storage. This eliminates clumping and the need for complicated procedures to keep your salts free-flowing. When the salts are kept dry this makes your measurements easier and more accurate. The material is easier-to-handle and will help avoid drying your salts in an oven or desiccator or breaking them apart by hand. Oxone Monopersulfate Compound REDI-DRI Certificate of Analysis COA

$20.81 - $797.60

-

Oxone PS-16 Monopersulfate (Non-Chlorine Shock)

OxoneTM PS-16 Monopersulfate | Non-Chlorine Shock Oxone PS-16 Compound is used as an active ingredient in disinfectant formulations (not registered as a biocide in USA), and as an oxidizing agent in other formulations, such as pool & spa non-chlorine shock oxidizers, denture cleansers and laundry bleaches. The grade is also used as a wet strength resin paper repulping aid, metal surface treatment agent, selective oxidizer in chemical synthesis, wool shrink-proofing treatment, waste water treatment and odor control agent. Applications: Water Treatment: It can be used to treat water, including drinking water and pool & spa water, due to its ability to kill bacteria and neutralize contaminants. Cleaning and Sanitization: It's used in various industrial cleaning products, especially for disinfecting surfaces or purifying air and water. Oxidation Reactions: In chemical processes, Oxone PS-16 can be used as a strong oxidizing agent to break down pollutants or aid in chemical synthesis. Active Ingredients: Potassium Peroxymonosulfate (KHSO₅) - 45% Other Ingredients - 55% Total -100% Bag Dimensions: 21"x14"x4" (55.1lbs) Chemical Formula: KHSO₅·KHSO₄·K₂SO₄ Molecular Weight: 614.8 g/mol CAS Registry Number: 70693-62-8, 7646-93-7, 7727-21-1 Appearance White Granules Odor: Odorless Density 2.35 g/cm3 (68 °F / 20 °C) Boiling Point: None Solubility in water: Highly and Readily Soluble at 297–357 g/L at 22°C (72°F) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H302, H314 GHS Precautionary Statements P260, P264, P270, P280, P301 + P312 + P330, P301 + P330 + P331, P303 + P361 + P353, P304 + P340 + P310, P305 + P351 + P338 + P310, P363, P405, P501 UN Identification Number: 3260 Proper Shipping Name: Corrosive solid, acidic, inorganic, n.o.s. (Monopersulfate Compound) Transport Hazard Class: 8 Packing Group: II DOT Placard: Oxone PS-16 Monopersulfate (SDS) Oxone PS-16 Monopersulfate Certificate of Analysis (COA)

$11.10 - $382.85

-

P10 Distillation Head - USA Made

P10 BVV™ Distillation Head P10 Distillation Head has 2 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 2 vigreux to allow for more packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$1,109.70 $832.28

-

Neocision P10V6 Neocision Distillation Head - USA Made

P10V6 Distillation Head P10V6 Distillation Head has 6 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and a 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$832.28

-

P2 Distillation Head - USA Made

P2 Distillation Head P2 Packable Distillation Head with 24/40 Joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$832.28

-

Neocision P2V4 Neocision Distillation Head - USA Made

P2V4 Neocision Distillation Head P2V4 Short Path Distillation Head includes 4 sets of Vigreux with 24/40 Joints and GL-14 Barb Connections. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Set of 4 Vigreux to allow for better seperation of fractions without packing material Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$1,040.35 $762.92

-

P5 Distillation Head - USA Made

P5 Distillation Head P5 Packable Distillation Head with 34/45 lower joint and 24/40 upper and side joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 5 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$762.92 $554.85

-

Neocision P5V6 Neocision Distillation Head - USA Made

P5V6 Distillation Head P5V6 Distillation Head has 6 sets of vigreux in the distillation column with 34/45 lower joint and 24/40 upper and side joints and includes GL-14 barb connections. MADE IN THE USA Designed for 5 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$762.92

-

Packing Rod Extension Screws

Packing Rod Extension Screw This packing rod extension screw allows you to combine our 24" Packing Rod Extension to our standard Stainless Steel Packing Rods making it easier to pack material columns greater than 36" in length.

$2.77

-

Part A 2" Stubby Metric Cam Lock Adaptor

Part A 2" Stubby Metric Cam Lock Adaptor This adapter converts 2" (50mm) male buttress pipe threads to a 2" male camlock. The adapter incorporates female buttress threads on one end and a male Camlock (also known as a quick-disconnect or QD) on the other for connecting pipes and valves with different ends. Made of tough polypropylene (PP), this adapter also incorporates an ethylene propylene diene monomer (EPDM) gasket for a leak-tight connection. Shallow profile ensures valve does not protrude past IBC tote cage. Key benefits: Converts 2" male buttress pipe thread to a 2" male quick-disconnect 2" long profile does not protrude past IBC cage during transport Combo camlock/NPT end allows use of a shallow NPT cap Made of PP EPDM gasket ensures a secure seal Suitable for use in a wide variety of liquid handling applications Proudly Made in the USA Material: Polypropylene (PP) is a tough plastic that has good chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color. Some examples of common products made with PP are dairy and medication containers. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclaving. It is not recommended for cold or sub-freezing temperatures. The Cary Company has an assortment of polypropylene plastics available for purchase, such as plastic caps and jars, which have a higher tolerance for chemical products. Disclaimer: This information has been provided as a general guide. It is the customer's responsibility to select the proper container for product and application compatibility. Material PP Dimensions 2.4" Dia. x 1.02" H Weight 0.1 lbs. Case Pack 200 ea. Case Dimensions 15" L x 15" W x 16" H Case Weight 20 lbs. Pallet Pack 4,800 ea. (24 Cases) Pallet Dimensions 40" L x 48" W x 60" H Pallet Weight 480 lbs. Country of Manufacture United States Gasket EPDM Rubber Gasket

$19.42 $9.71

-

Part A 2" Stubby NPT to Cam Lock Adaptor

Part A 2" Stubby NPT to Cam Lock Adaptor This adapter converts 2" (50mm) male NPT pipe threads to a 2" male camlock. The adapter incorporates female NPT threads on one end and male camlock (also known as a quick disconnect or QD) on the other for connecting pipes and valves with different ends. Made of tough polypropylene (PP), this adapter also incorporates an ethylene propylene diene monomer (EPDM) gasket for a leak-tight connection. Shallow profile ensures valve does not protrude past IBC tote cage. Key benefits: Converts 2" male NPT pipe thread to a 2" male camlock 2" long profile does not protrude past IBC cage during transport Made of PP EPDM gasket ensures a secure seal Suitable for use in a wide variety of liquid handling applications Proudly Made in the USA Material: Polypropylene (PP) is a tough plastic that has good chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color. Some examples of common products made with PP are dairy and medication containers. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclaving. It is not recommended for cold or sub-freezing temperatures. The Cary Company has an assortment of polypropylene plastics available for purchase, such as plastic caps and jars, which have a higher tolerance for chemical products. Disclaimer: This information has been provided as a general guide. It is the customer's responsibility to select the proper container for product and application compatibility. Material PP Dimensions 2.4" Dia. x 1.02" H Weight 0.1 lbs. Case Pack 200 ea. Case Dimensions 15" L x 15" W x 16" H Case Weight 20 lbs. Pallet Pack 6,000 ea. (30 Cases) Pallet Dimensions 40" L x 48" W x 60" H Pallet Weight 600 lbs. Country of Manufacture United States Gasket EPDM Rubber Gasket

$15.26 $9.71

-

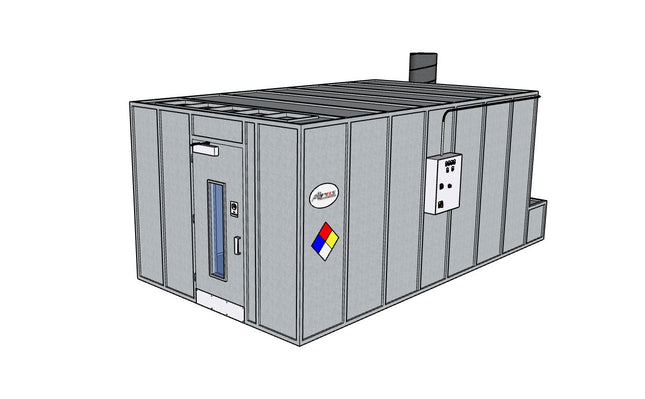

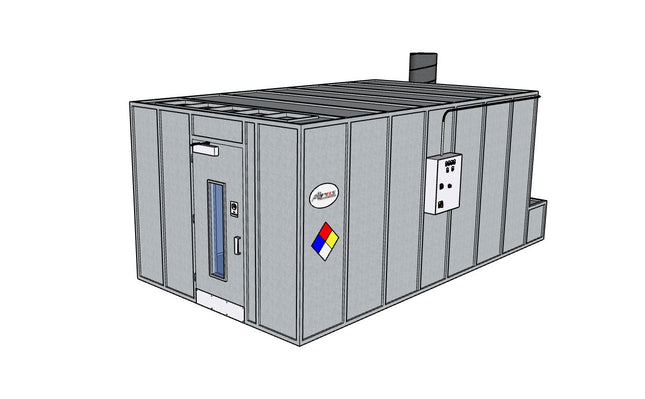

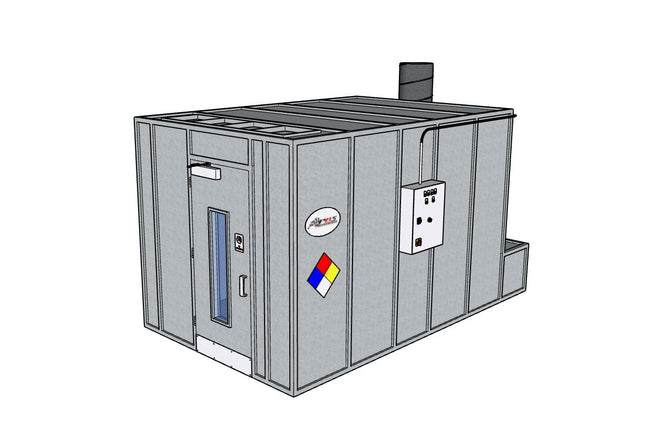

PBS Industries PBS Industries EXT101012 Extraction Room

PBS Industries EXT101012 Extraction Room (1) Model EXT101012 Extraction Room Interior working dimensions: 10'-0" wide X 10'-0" tall X 12'-0" long. Approximate overall dimensions: 10'-4" wide X 10'-2" tall X 14'-4" long. Scope: Clean air flows into the room through the filtered ceiling at the front, passing through the work area, and exits through the exhaust plenum located in the rear of the room. Air is drawn through the exhaust plenum and discharged upward into the atmosphere via the exhaust stack(s). Panels: Panels are fabricated from 18-gauge quality galvanized steel, flanged and precision punched on 6" centers. Panels are fastened together with 5/16 bolts for maximum rigidity. Panel seams and any penetration holes added for extraction equipment must be sealed with provided non-flammable caulk. Meets ATMC-838 Specifications. A total of (2) Explosion Proof light fixtures will be provided for illumination: Lighting is provided by 48" long, 3-row, 73 watts, C1D1 LED lights. Fixtures are rated for Class I Div. 1 area (Explosion Proof) group C and D. All fixtures are UL844 listed and approved for their intended use and placement. Lights will accept either 120V or 277V power and carries a 5-year limited warranty. (1) - 18” 1.5 HP Exhaust fan rated for 4,000 CFM @ 0.5” Static PressureTotal CFM exhausted: 4,000 CFM. (UL Listed, Explosion Proof Motor) A precision balanced, fabricated, tube axial type duct fan with aluminum non-sparking fan blade moves air through the fan. Bearings are mounted in rubber isolators for smooth operation. The motor, drive, and bearings are isolated from the exhaust air stream. The bearings are sized with a minimum average life, per AFBMA, in excess of 200,000 hours when operating at the maximum RPM of the fan size. Design Note: Air flow is calculated at approximately 3 air changes per minute. Infrared Gas Detection System: Control panel is housed in a NEMA 4X enclosure that is waterproof, chemical and weather resistant. The control box includes an audible and visual alarm to alert personnel of gas detection including gas type and concentration level. When gas is detected above the appropriate setting the exhaust fan will increase to full speed to purge gas from the room. UL Listed infrared transmitter – Detects combustibles and CO2. Explosion Proof Construction with non-intrusive calibration and is rated for Class 1 Div. 1 Groups B, C, D. (1) - Personnel access door(s): Personnel access door(s) are double wall 18-Ga. galvanized steel units sized at 36" x 84” and are provided pre-hung in a heavy gauge steel frame ready for mounting to the room. The mounting hardware includes an observation window, FM approved panic type safety latch and two 6" door pulls. Room also includes a door closing device that is UL Listed and ADA compliant. Closer can be mounted on the interior or exterior as well as the left or right side of the door. Door closer is constructed of aluminum and is ANSI A156.4 compliant. UL/ ETL Listed Control Equipment: A NEMA12 enclosure pre-wired and tested by manufacturer for simple hookup. Control panel includes main disconnect switch, class 10 motor protection, light contactor, fuse block, and field wiring terminal strip to easily connect interlock circuits such as door limit switches, and fire suppression. Includes fan failure alarm circuit and auto fan override relay. The class 10 motor protector offers maximum motor protection by being individually calibrated for the smallest and largest current it can handle and includes automatic ambient temperature compensation over a range of -13F to +140F. Code Compliance: All PBS extraction rooms are designed to meet or exceed the requirements and recommendations of the National Fire Protection Association (NFPA), Codes: NFPA 1-2018, 33, 55-2016, 58-2020, 70-2017, 497-2017. NEMA 250-2018. ASME BPVC VIII Div. 1-2019, IBC. IFC-2018. IMC as well as the Occupational Health and Safety Administration (OSHA) CFR 29.1910.107 covering the operation and construction of ventilated rooms. All PBS extraction rooms are peer reviewed and UL 1389 compliant with regard to component operation, placement and intended use.

$37,953.25 - $55,485.18

-

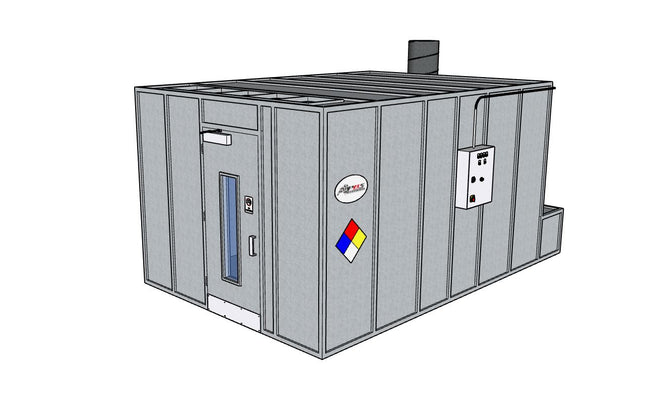

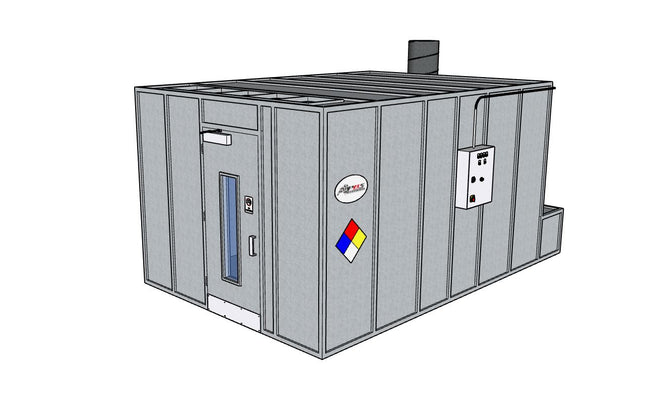

PBS Industries PBS Industries EXT10812 Extraction Room

PBS Industries EXT10812 Extraction Room PBS Industries, LLC is pleased to offer the following proposal for your consideration. (1) Model EXT10812 l Extraction Room Interior working dimensions: 10'-0" wide X 8'-0" tall X 12'-0" long. Approximate overall dimensions: 10'-4" wide X 8'-2" tall X 14'-4" long. Scope: Clean air flows into the room through the filtered ceiling at the front, passing through the work area, and exits through the exhaust plenum located in the rear of the room. Filtered exhaust air is drawn through the exhaust plenum and discharged upward into the atmosphere via the exhaust stack(s). Panels: Panels are fabricated from 18-gauge quality galvanized steel, flanged and precision punched on 6" centers. Panels are fastened together with 5/16 bolts for maximum rigidity. Panel seams and any penetration holes added for extraction equipment must be sealed with provided non-flammable caulk. Meets ATMC-838 Specifications. A total of (1) Explosion Proof light fixtures will be provided for illumination: Lighting is provided by 4’ long, 3-Row, 68 watt, LED fixture. Fixture is rated for Class I Div. 1 area (Explosion Proof) group C and D. All fixtures are UL844 listed and approved for their intended use and placement. Fixtures are supplied with 120V-277V power, diffused optic, powder coated black, and carry a 5-year limited warranty. (1) - 18” .75 HP Exhaust fan rated for 3,000 CFM @ 0.5” Static Pressure Total CFM exhausted: 3,000 CFM. (UL Listed, Explosion Proof Motor) A precision balanced, fabricated, tube axial type duct fan with aluminum non-sparking fan blade moves air through the fan. Bearings are mounted in rubber isolators for smooth operation. The motor, drive, and bearings are isolated from the exhaust air stream. The bearings are sized with a minimum average life, per AFBMA, in excess of 200,000 hours when operating at the maximum RPM of the fan size. Design Note: Purge air flow is calculated at approximately 3 air changes per minute. Constant operational airflow is approximately 800-1000 CFM. Infrared Gas Detection System: Control panel is housed in a NEMA 4X enclosure that is waterproof, chemical and weather resistant. The control box includes an audible and visual alarm to alert personnel of gas detection including gas type and concentration level. When gas is detected above the appropriate setting the exhaust fan will increase to full speed to purge gas from the room. UL Listed infrared transmitter – Detects combustibles or CO2. Sensor is pre-calibrated for your specific gas or solvent requirement. Explosion Proof Construction with non-intrusive calibration and is rated for Class 1 Div. 1 Groups B, C, D. Contact us should multiple gases or solvents be required. (1) - Personnel access door(s): Personnel access door(s) are double wall 18-Ga. galvanized steel units sized at 36" x 84” and are provided pre-hung in a heavy gauge steel frame ready for mounting to the room. The mounting hardware includes an observation window, FM approved panic type safety latch and two 6" door pulls. Room also includes a door closing device that is UL Listed and ADA compliant. Closer can be mounted on the interior or exterior as well as the left or right side of the door. Door closer is constructed of aluminum and is ANSI A156.4 compliant. UL/ ETL Listed Control Equipment: A NEMA12 enclosure pre-wired and tested by manufacturer for simple hookup. Control panel includes main disconnect switch, class 10 motor protection, light contactor, fuse block, and field wiring terminal strip to easily connect interlock circuits such as door limit switches, and fire suppression. Includes fan failure alarm circuit and auto fan override relay. The class 10 motor protector offers maximum motor protection by being individually calibrated for the smallest and largest current it can handle and includes automatic ambient temperature compensation over a range of -13F to +140F. Code Compliance: All PBS extraction rooms are designed to meet or exceed the requirements and recommendations of the National Fire Protection Association (NFPA), Codes: NFPA 1-2018, 33, 55-2016, 58-2020, 70-2017, 497-2017. NEMA 250-2018. ASME BPVC VIII Div. 1-2019, IBC. IFC-2018. IMC as well as the Occupational Health and Safety Administration (OSHA) CFR 29.1910.107 covering the operation and construction of ventilated rooms. PBS extraction rooms are UL 1389 compliant with regard to component placement, operation, and intended use. Peer Review included. NOTE PLEASE: If you would like more than one ADD-on please contact us

$46,056.86

-

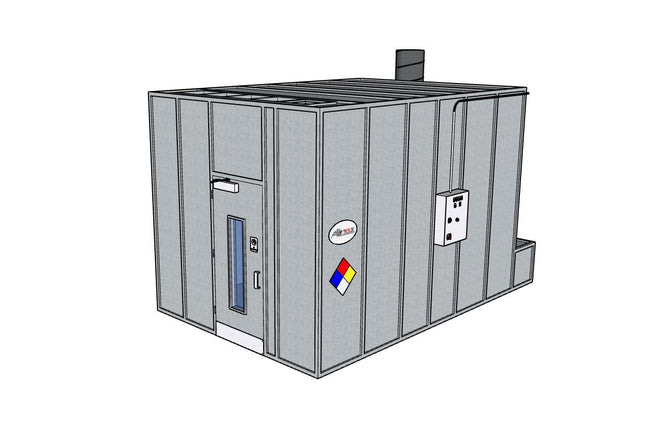

PBS Industries PBS Industries EXT10815 Extraction Room

PBS Industries EXT10815 Extraction Room (1) Model EXT10815 Extraction Room Interior working dimensions: 10'-0" wide X 8'-0" tall X 15'-0" long. Approximate overall dimensions: 10'-4" wide X 8'-2" tall X 17'-4" long. Scope: Clean air flows into the room through the filtered ceiling at the front, passing through the work area, and exits through the exhaust plenum located in the rear of the room. Air is drawn through the exhaust plenum and discharged upward into the atmosphere via the exhaust stack(s). Panels: Panels are fabricated from 18-gauge quality galvanized steel, flanged and precision punched on 6" centers. Panels are fastened together with 5/16 bolts for maximum rigidity. Panel seams and any penetration holes added for extraction equipment must be sealed with provided non-flammable caulk. Meets ATMC-838 Specifications. A total of (3) Explosion Proof light fixtures will be provided for illumination: Lighting is provided by 48" long, 3-row, 73 watts, C1D1 LED lights. Fixtures are rated for Class I Div. 1 area (Explosion Proof) group C and D. All fixtures are UL844 listed and approved for their intended use and placement. Lights will accept either 120V or 277V power and carries a 5-year limited warranty. (1) - 18” 1.5 HP Exhaust fan rated for 4,000 CFM @ 0.5” Static PressureTotal CFM exhausted: 4,000 CFM. (UL Listed, Explosion Proof Motor) A precision balanced, fabricated, tube axial type duct fan with aluminum non-sparking fan blade moves air through the fan. Bearings are mounted in rubber isolators for smooth operation. The motor, drive, and bearings are isolated from the exhaust air stream. The bearings are sized with a minimum average life, per AFBMA, in excess of 200,000 hours when operating at the maximum RPM of the fan size Design Note: Air flow is calculated at approximately 3 air changes per minute. Infrared Gas Detection System: Control panel is housed in a NEMA 4X enclosure that is waterproof, chemical and weather resistant. The control box includes an audible and visual alarm to alert personnel of gas detection including gas type and concentration level. When gas is detected above the appropriate setting the exhaust fan will increase to full speed to purge gas from the room. UL Listed infrared transmitter – Detects combustibles and CO2. Explosion Proof Construction with non-intrusive calibration and is rated for Class 1 Div. 1 Groups B, C, D. (1) - Personnel access door(s): Personnel access door(s) are double wall 18-Ga. galvanized steel units sized at 36" x 84” and are provided pre-hung in a heavy gauge steel frame ready for mounting to the room. The mounting hardware includes an observation window, FM approved panic type safety latch and two 6" door pulls. Room also includes a door closing device that is UL Listed and ADA compliant. Closer can be mounted on the interior or exterior as well as the left or right side of the door. Door closer is constructed of aluminum and is ANSI A156.4 compliant. UL/ ETL Listed Control Equipment: A NEMA12 enclosure pre-wired and tested by manufacturer for simple hookup. Control panel includes main disconnect switch, class 10 motor protection, light contactor, fuse block, and field wiring terminal strip to easily connect interlock circuits such as door limit switches, and fire suppression. Includes fan failure alarm circuit and auto fan override relay. The class 10 motor protector offers maximum motor protection by being individually calibrated for the smallest and largest current it can handle and includes automatic ambient temperature compensation over a range of -13F to +140F. Code Compliance: All PBS extraction rooms are designed to meet or exceed the requirements and recommendations of the National Fire Protection Association (NFPA), Codes: NFPA 1-2018, 33, 55-2016, 58-2020, 70-2017, 497-2017. NEMA 250-2018. ASME BPVC VIII Div. 1-2019, IBC. IFC-2018. IMC as well as the Occupational Health and Safety Administration (OSHA) CFR 29.1910.107 covering the operation and construction of ventilated rooms. All PBS extraction rooms are peer reviewed and UL 1389 compliant with regard to component operation, placement and intended use.

$55,468.53

-

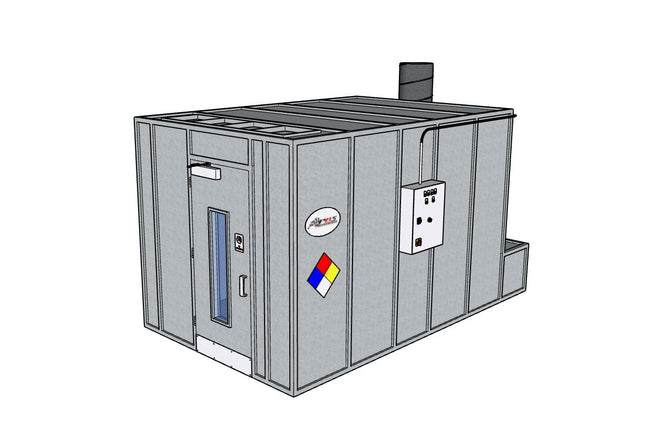

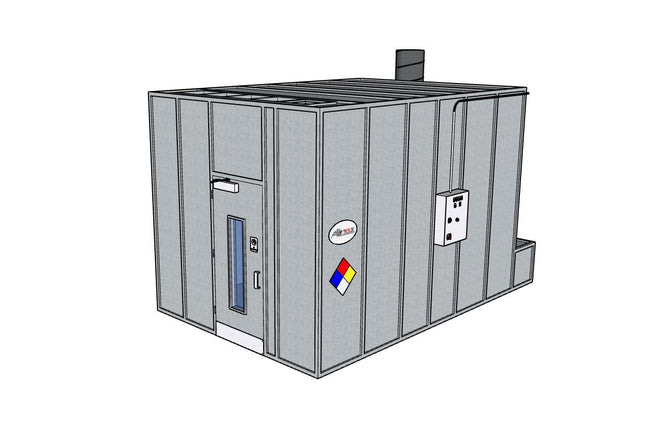

PBS Industries PBS Industries EXT8810 Extraction Room

PBS Industries EXT8810 Extraction Room PBS Industries, LLC is pleased to offer the following proposal for your consideration. (1) Model EXT8810 Extraction Room Interior working dimensions: 8'-0" wide X 8'-0" tall X 10'-0" long. Approximate overall dimensions: 8'-4" wide X 8'-2" tall X 12'-4" long. Scope: Clean air flows into the room through the filtered ceiling at the front, passing through the work area, and exits through the exhaust plenum located in the rear of the room. Air is drawn through the exhaust plenum and discharged upward into the atmosphere via the exhaust stack(s). Panels: Panels are fabricated from 18-gauge quality galvanized steel, flanged and precision punched on 6" centers. Panels are fastened together with 5/16 bolts for maximum rigidity. Panel seams and any penetration holes added for extraction equipment must be sealed with provided non-flammable caulk. Meets ATMC-838 Specifications. A total of (1) Explosion Proof light fixtures will be provided for illumination: Lighting is provided by 4’ long, 3-Row, 68 watt, LED fixture. Fixture is rated for Class I Div. 1 area (Explosion Proof) group C and D. All fixtures are UL844 listed and approved for their intended use and placement. Fixtures are supplied with 120V-277V power, diffused optic, powder coated black, and carry a 5-year limited warranty. (1) - 18” .75 HP Exhaust fan rated for 2,000 CFM @ 0.5” Static Pressure Total CFM exhausted: 2,000 CFM. (UL Listed, Explosion Proof Motor) A precision balanced, fabricated, tube axial type duct fan with aluminum non-sparking fan blade moves air through the fan. Bearings are mounted in rubber isolators for smooth operation. The motor, drive, and bearings are isolated from the exhaust air stream. The bearings are sized with a minimum average life, per AFBMA, in excess of 200,000 hours when operating at the maximum RPM of the fan size. Design Note: Purge air flow is calculated at approximately 3 air changes per minute. Constant operational airflow is approximately 800-1000 CFM. Infrared Gas Detection System:Control panel is housed in a NEMA 4X enclosure that is waterproof, chemical, and weather resistant. The control box includes an audible and visual alarm to alert personnel of gas detection including gas type and concentration level. When gas is detected above the appropriate setting the exhaust fan will increase to full speed to purge gas from the room. UL Listed infrared transmitter – Detects combustibles or CO2. Sensor is pre-calibrated for your specific gas or solvent requirement. Explosion Proof Construction with non-intrusive calibration and is rated for Class 1 Div. 1 Groups B, C, D. Contact us should multiple gases or solvents be required. (1) - Personnel access door(s): Personnel access door(s) are double wall 18-Ga. galvanized steel units sized at 36" x 84” and are provided pre-hung in a heavy gauge steel frame ready for mounting to the room. The mounting hardware includes an observation window, FM approved panic type safety latch and two 6" door pulls. Room also includes a door closing device that is UL Listed and ADA compliant. Closer can be mounted on the interior or exterior as well as the left or right side of the door. Door closer is constructed of aluminum and is ANSI A156.4 compliant. UL/ ETL Listed Control Equipment: A NEMA12 enclosure pre-wired and tested by manufacturer for simple hookup. Control panel includes main disconnect switch, class 10 motor protection, light contactor, fuse block, and field wiring terminal strip to easily connect interlock circuits such as door limit switches, and fire suppression. Includes fan failure alarm circuit and auto fan override relay. The class 10 motor protector offers maximum motor protection by being individually calibrated for the smallest and largest current it can handle and includes automatic ambient temperature compensation over a range of -13F to +140F. Code Compliance: All PBS extraction rooms are designed to meet or exceed the requirements and recommendations of the National Fire Protection Association (NFPA), Codes: NFPA 1-2018, 33, 55-2016, 58-2020, 70-2017, 497-2017. NEMA 250-2018. ASME BPVC VIII Div. 1-2019, IBC. IFC-2018. IMC as well as the Occupational Health and Safety Administration (OSHA) CFR 29.1910.107 covering the operation and construction of ventilated rooms. All PBS extraction rooms are peer reviewed and UL 1389 compliant with regard to component operation, placement and intended use. All PBS extraction rooms are designed to meet or exceed the requirements and recommendations of the National Fire Protection Association (NFPA), Codes: NFPA 1-2018, 33, 55-2016, 58-2020, 70-2017, 497-2017. NEMA 250-2018. ASME BPVC VIII Div. 1-2019, IBC. IFC-2018. IMC as well as the Occupational Health and Safety Administration (OSHA) CFR 29.1910.107 covering the operation and construction of ventilated rooms. All PBS extraction rooms are peer reviewed and UL 1389 compliant with regard to component operation, placement and intended use. NOTE PLEASE: If you would like more than one ADD-on please contact us

$39,029.66

-

Pure-Flo Perform 5000 Highly Acid Activated Bleaching & Decolorizing Bentonite

Pure-Flo® Perform 5000 Highly Activated Bentonite Clay for Bleaching & Decolorizing Edible Oils pH: 2.7 Pure-Flo® Perform 5000 provides superior bleaching activity for demanding oils. Effective with all types of difficult-to-bleach oil. Pure-Flo® Perform 5000 Technical Data Sheet.pdf Perform 5000 Safety Data Sheet Excellent metals adsorption characteristics (P, Ca, Fe, Mg, Ni, etc.) Excellent Chlorophyll removal Excellent Red and Blue color body removal. Removes soaps and phospholipids Outstanding filtration characteristics, including long filtration cycles and less pressure build up at cycle end. ph:2.7 FDA GRAS (Generally Recognized as Safe) - This product is safe for processing food, as long as its not part of the end product being consumed. NSF- HACCP *Prior to down packing this product was certified Kosher & Hallal. It does not retain its certifications after down packing, Sorry BVV™ doesn't have an on staff Rabbi or Imam on site to re-establish those certifications. Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several weeks lead time and require a forklift or pallet jack

$27.74 - $3,121.04

-

Pure-Flo Perform 6000 Highly Activated Bleaching & Decolorizing Bentonite

Highly Activated Bentonite Clay for Bleaching & Decolorizing Edible Oils pH: 2.5 Pure-Flo® Perform 6000 is a highly activated bentonite clay that is used to purify extremely difficult to bleach oils with the most challenging levels of chlorophyll and color bodies. Particle Size: 325 Mesh Color: Beige Performance Features & Benefits: Filter Aid Removes phosolipids Excellent Metal adsorption (P, Ca, Fe, Mg, etc.) Effective with all types of difficult-to-bleach oil Top chlorophyll removal in its class & improved red color reduction pH 2.5 FDA GRAS (Generally Recognized as Safe) - This product is safe for processing food, as long as its not part of the end product being consumed. Pure-Flo® Perform 6000 Data Sheet.pdf Pure-Flo® Perform 6000 Safety Data Sheet (SDS).pdf Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several weeks lead time and require a forklift or pallet jack Note: Container style and color may vary. Product is sold by weight which may result in container not being full.

$27.74 - $3,225.08

-

Pinch Clamp 1-3/8"-1-1/2"

Pinch Clamp 1-3/8"-1-1/2" Replacement pinch clamp that will secure the cover over the heat pad after disassembling the Lab Dosing Gun:

$5.55

-

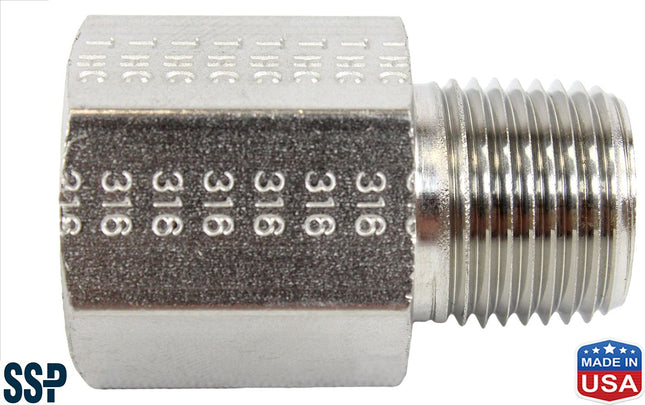

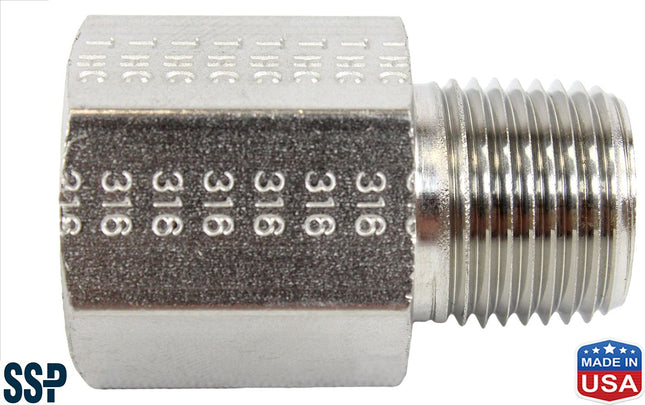

SSP Corporation Pipe Cap

SSP - Pipe Cap SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$9.71 $6.94

-

SSP Corporation Pipe Cross

SSP - Pipe Cross SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications: Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$34.68 $18.03

-

Pipe Cross

BVV Pipe Cross BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. Stainless Steel Pipe Crosses are used to split flow 4 ways and create manifolds like the Bi-Flow manifold on Bidirectional extraction systems that BVV™ is known for. They can also be connected together creating even larger manifolds when combined with valves and other stainless steel fittings. BVV™ Pipe Cross - Data Sheet Specifications Material 304 Stainless Steel Connection Type 1/4"-18 FNPT 3/8"-18 FNPT 1/2"-14 FNPT Sizes Available: 1/4" 3/8" 1/2"

$34.68 - $48.55

-

Pipe Hangers with 1/2" FNPT Mounting

Pipe Hangers with 1/2" FNPT Mounting Pipe Hangers Designed with 1/2" FNPT mounting threads. They range in sizes from 2.5" - 14" Diameter. ***NOTE: If you are planning to use a pipe hanger on a Dewaxing or Jacketed Column please choose a size that is 2" larger than the tri-clamp size.

$48.55 - $97.10

-

Pipe Hangers with Bracket Mount

Pipe Hangers Pipe Hangers Designed to fit on our racks. They range in sizes from 1.5" - 14" Diameter. Disclaimer: 4" and 6" Brackets have a new design incorporating the hang on bracket as one piece. Depending on size and availability, these may come with blue or purple rubber lining. ***NOTE: If you are planning to use a pipe hanger on a Dewaxing or Jacketed Column please choose a size that is 2" larger than the tri-clamp size.

$48.55 - $145.65

-

Pipe Nipple