Products

-

Plastic End Caps for Tri-Clamp Parts - 2 Pack

Plastic End Caps for Tri-Clamp/ Tri Clover Parts - 2 Pack These plastic end caps are for covering and protecting the ends of Tri-Clamp parts from damage or allowing the user to fill a column while capping off the other end and come in a pack of 2.

$2.78 - $3.47

-

Plastic Spigot for 1 Gallon Jugs

Plastic Spigot for 1 Gallon Jugs This self-venting spigot eliminates chugging and splashing. Made HDPE & polypropylene Fits 1QT or 1 Gallon containers sold by BVV™

$8.33

-

Polycarbonate Tri-Clamp Sight Glass - Made in USA

Polycarbonate Tri-Clamp/ Tri Clover Sight Glass Polycarbonate Tri-Clamp sight glasses are a great and cost effective way to add viewing ports to your system. These sight glasses are 1 piece CNC machined out of 0.25" thick sheets of polycarbonate and rated up to 250, 225, and 175 PSI for 1.5", 2", and 3" Tri-Clamp sizes. These sight glasses come with a protective film of plastic over the viewing area to protect it from being damaged during shipping and testing the customer will need to remove this upon usage. ***Note: Gasket and Clamp sold separately. Specifications: Material Polycarbonate Window Diameter: 1.5" 1-1/4" 2" 1-3/4" 3" 2-3/4" Maximum PSI @70F: 1.5" 250 2" 225 3" 175

$38.85 - $54.12

-

Polyethylene Glycol 400 - PEG 400

Polyethylene Glycol 400 Polyethylene glycol 400 has an average molecular weight of 400. It is a clear, viscous liquid at room temperature. APPLICATIONS • Chemical Intermediate• Plasticizer• In cosmetics for preparation of ointments and lotions.• As a mold release agent and lubricant for both natural and synthetic products. Physical Properties Flash point, PMCC, °F 390 Flash point, PMCC, °C 199 Refractive index, 25°C 1.463 Density, g/ml, 20°C (68°F) 1.1254 Weight, lbs/US gal, 20°C (68°F) 9.39 Freezing Range, °F 39-46 Freezing Range, °C 4-8 Viscosity, kinematic cSt at 25°C (77°F) 84 cSt at 98.9°C (210°F) 7.3 Chemical Properties Molecular Weight (range) 380-420 Average number of EO units 8.7 Water Solubility Soluble Potassium acetate, wt% 0.02-0.2 pH, 5% aqueous solution 4.5-7.0 Water, wt% 0.5 max. Color, Pt-Co 50 max. Hydroxyl number, mg KOH/g 267-295 Appearance, 20°C Clear The expiration date is 3 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$34.69 - $5,134.22

-

Polyscience Polyscience 1.5 HP Chiller, Positive Displacement Pump; Air-Cooled

Polyscience 1.5 HP Chiller, Positive Displacement Pump; Air-Cooled Description: 1.5 HP Chiller, Positive Displacement Pump; Air-Cooled Display: LED Connectivity: Optional: RS232, RS485 Working Temperature Range °C: 5° to 35° Temperature Stability °C: ±0.5° Temperature Calibration Capability: 1-point Pump Type: Positive Displacement Key Features High capacity cooling for lasers, electron microscopes, and other laboratory applications Small footprint conserves floor space Displays temperature and pressure or flow rate simultaneously User-adjustable temperature, pressure, and flow rate alarms Simple operation and maintenance Air- or water-cooled Positive displacement (PD) or turbine (T) pump; other pump options also available Common Specifications Working Temperature Range °F 41° to 95° Working Temperature Range °C 5° to 35° Reservoir Capacity (gallons) 3.5 Reservoir Capacity (liters) 13.25 Reservoir/Tank Material Polyethylene Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Cleanable Fluid Filter Yes Temperature Stability °F ±0.9° Temperature Stability °C ±0.5° Display LED Display Resolution (Read) 0.1 Pump Type Positive Displacement Process Connections 1/2" (F) NPT Over-Temperature Protection / Failsafe Heater Control Yes Reservoir Liquid Level Indicator Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 30.5 x 19 x 26 in Overall Dimensions (L x W x H) (cm) 78 x 48 x 66 cm Compressor Size (HP) 1.5 Refrigerant R134a Shipping Weight (pounds) 340.0 Shipping Weight (kilograms) 154.0 Catalog Page Number 104 Hz (Hertz) 60 Hz Only 50 Hz Only Part Number 6860P46A270D 6850P46A270E Maximum Pressure (psi) 100.0 83.0 Maximum Pressure (bar) 6.90 5.72 Maximum Pressure Flow Rate (gpm) 3.50 2.90 Maximum Pressure Flow Rate (l/min) 13.2 11.0 Cooling Capacity @ +10°C (W) 4420 3715 Cooling Capacity @ +20°C (W) 5200 4371 Cooling Capacity @ +30°C (W) 5980 5027 Heater Wattage 1000 1000 Electrical Requirements (VAC/Hz/Ph/A) 230/60/1/21.1 240/50/1/20.8 Regulatory Approvals TUV CSA, CUL, CE

$14,213.46

-

Polyscience Polyscience 10 Liter General Purpose Water Bath

Polyscience 10 Liter General Purpose Water Bath Key Features: Displays actual and set point temperature simultaneously Three push-button pre-sets for frequently used temperatures Integrated timer Hinged gable cover Calibration capability Reservoir sizes from 2 to 28 liters Reservoir made of 304 Stainless Steel Reservoir drain (10 liter and larger baths) Primary and automatic safety thermostats Also compatible with waterless bath beads Specifications Working Temperature Range °F Ambient +10° to 212° Reservoir Capacity (liters) 10 Reservoir/Tank Material Stainless Steel Reservoir Cover Hinged Gable Working Access (L x W x D) (inches) 10.6 x 11.6 x 6 Temperature Stability °F ±0.2° Display 3.25" Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Maximum Ambient Temperature °F 104° Overall Dimensions (L x W x H) (inches) 17 x 15.5 x 15.5 Shipping Weight (pounds) 22.0 60Hz Only Part Number WBE10A11B Included Hardware Sample Tray Heater Wattage 1000 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/8.6 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Regulatory Approvals: CE

$1,351.55 $832.58

-

Polyscience Polyscience 15 Liter Advanced Digital Heated Circulator

Polyscience 15 Liter Advanced Digital Heated Circulator Note: This Item has a lead time of 2 weeks depending on stock availability. Specification Description 200, 15 L Htg. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C Ambient +10° to 200° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F Ambient + 20° to 392° Working Temperature Range °C Ambient +10° to 200° Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Cooling Coil Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95 Maximum Ambient Temperature °C 35 Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 16.6 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 42.2 cm Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 62.0 Shipping Weight (kilograms) 28.1 Catalog Page Number 56-57 60 Hz Only Part Number AD15H200-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/10 Regulatory Approvals ETL 50 Hz Only Part Number AD15H200-A12E Maximum Pressure (psi) 3.6 Maximum Pressure (bar) 0.25 Maximum Pressure Flow Rate (gpm) 4.40 Maximum Pressure Flow Rate (l/min) 16.7 Maximum Suction Flow Rate (gpm) 3.2 Maximum Suction Flow Rate (l/min) 12.2 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16", and 1/4" NPT to M16 adapter Heater Wattage 2200 Electrical Requirements (VAC/Hz/Ph/A) 240/50/1/10 Regulatory Approvals CE Key Features: Intuitive 3.75" (9.5 cm) display with touch-pad control 4 languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Regulatory Approvals ETL Approvals CE Approvals Polyscience Data Sheet User Manual

$4,995.46 - $5,030.15

-

Polyscience Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C)

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C) ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Description: -30, 15 L Ref. Circulator Controller Type: Advanced Digital Display: 3.75" Touch-Pad LCD Connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported: 4: French, German, Spanish, English Swivel 180 Rotating Controller: Yes Working Temperature Range °C: -30° to 200° Temperature Stability °C: ±0.01° Fluid Optimization/Specific Heat Tuning: Automatic and/or user-adjustable Temperature Calibration Capability: 1-point Working Access (L x W x D) (cm): 21.2 x 27.6 x 14 cm Pump Type: Pressure/Suction External Temperature Control Capability: Yes Flammability Class (DIN 12876-1): III (FL) Specifications Working Temperature Range °F -22° to 392° Working Temperature Range °C -30° to 200° Nominal Cooling Capacity @ +20C (W) 915 Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 26.9 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 68.3 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 118.0 Shipping Weight (kilograms) 53.5 60Hz Part Number AD15R-30-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 165 Cooling Capacity @ 0°C (W) 505 Cooling Capacity @ +20°C (W) 915 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/13 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Circulating Bath Operator's Manual

$8,811.43

-

Polyscience Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-40°C/200°C)

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-40°C/200°C) Specification Description -40, 15 L Ref. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C -40° to 200° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F -40° to 392° Working Temperature Range °C -40° to 200° Nominal Cooling Capacity @ +20C (W) 1000 Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 26.9 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 68.3 cm Refrigerant R452A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 118.0 Shipping Weight (kilograms) 53.5 Catalog Page Number 40-41 60 Hz Only Part Number AD15R-40-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 265 Cooling Capacity @ 0°C (W) 650 Cooling Capacity @ +20°C (W) 1000 Cooling Capacity @ +100°C (W) 1000 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/13 Regulatory Approvals ETL Key Features: Intuitive 3.75" (9.5cm) display with touch-pad control 4 Languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Operators Manual

$9,713.39

-

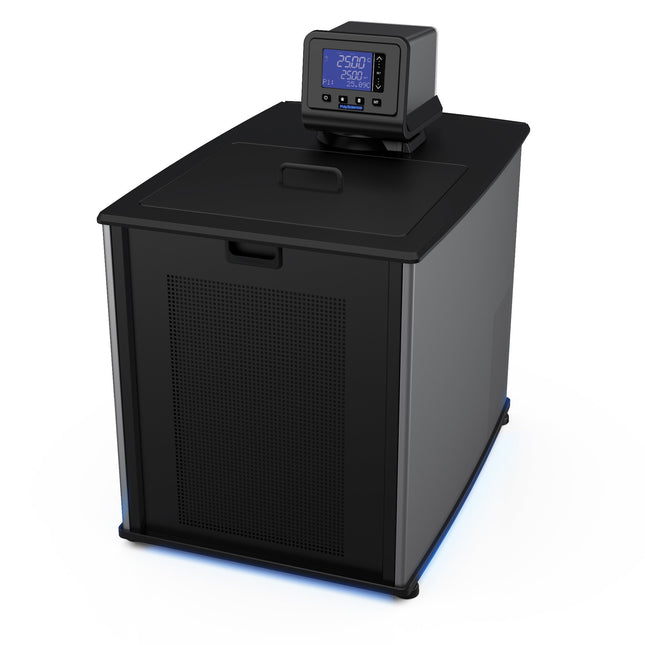

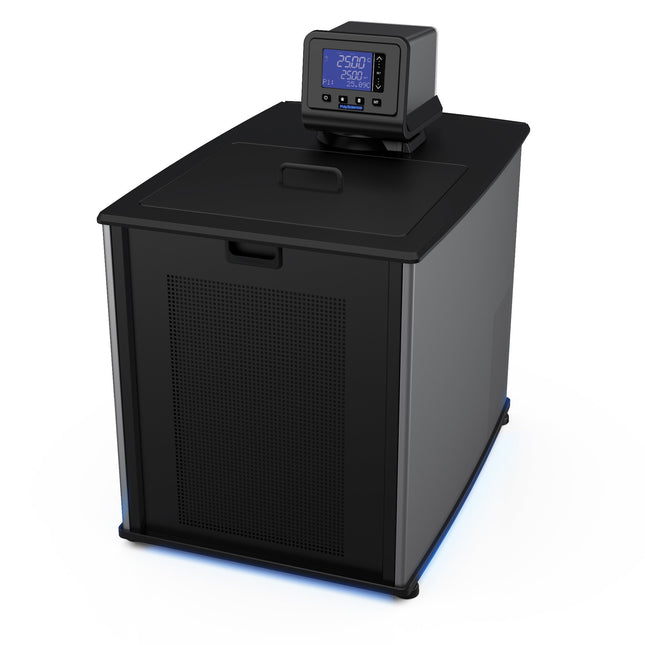

Polyscience Polyscience 28 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C)

Polyscience 28 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C) Specification Description -30, 28 L Ref. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C -30° to 200° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 31.4 x 35.9 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F -22° to 392° Working Temperature Range °C -30° to 200° Nominal Cooling Capacity @ +20C (W) 915 Reservoir Capacity (gallons) 7.4 Reservoir Capacity (liters) 28 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 12.35 x 14.13 x 5.5 in Working Access (L x W x D) (cm) 31.4 x 35.9 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Cooling Coil Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 26.5 x 18 x 26.9 in Overall Dimensions (L x W x H) (cm) 67.2 x 45.7 x 68.3 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 146.0 Shipping Weight (kilograms) 66.1 Catalog Page Number 40-41 60 Hz Only Part Number AD28R-30-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 165 Cooling Capacity @ 0°C (W) 505 Cooling Capacity @ +20°C (W) 915 Cooling Capacity @ +100°C (W) 915 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/10 Regulatory Approvals ETL Key Features: Intuitive 3.75" (9.5cm) display with touch-pad control 4 Languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Certifications Regulatory Approvals: CE Regulatory Approvals: ETL Operator's Manual

$9,713.39

-

Polyscience Polyscience 3 HP High Capacity Chiller; Air-Cooled - Up to 10.5kW @ 20°C

Polyscience 3 HP High Capacity Chiller; Air-Cooled - Up to 10.5kW @ 20°C Key Specifications Description: 3 HP Chiller; Air-Cooled; Up to 10.5kW @ 20°C Display: LED Connectivity: Standard: RS232; Optional: RS485 Working Temperature Range °C: 5° to 35° Temperature Stability °C: ±0.5° Temperature Calibration Capability: 1-point Key Features Chillers 2HP and up are not available outside of the United States High capacity cooling for lasers, EDM equipment, injection molding, and other heat removal applications Displays temperature and pressure or flow rate simultaneously User-adjustable temperature, pressure, and flow rate alarms Simple operation and maintenance Air- or water-cooled (3 HP models) Wide variety of pump options available Common Specifications Working Temperature Range °F 41° to 95° Working Temperature Range °C 5° to 35° Cooling Capacity Up to 10.5kW @ 20°C Reservoir Capacity (gallons) 7 Reservoir Capacity (liters) 26.5 Reservoir/Tank Material Contact PolyScience for Options Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Cleanable Fluid Filter Yes Temperature Stability °F ±0.9° Temperature Stability °C ±0.5° Display LED Display Resolution (Read) 0.1 Pump Type Contact PolyScience for Options Process Connections 3/4" (F) NPT Over-Temperature Protection / Failsafe Heater Control Yes Reservoir Liquid Level Indicator Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 30.5 x 37 x 42 in Overall Dimensions (L x W x H) (cm) 78 x 94 x 107 cm Compressor Size (HP) 3 Refrigerant R134a Shipping Weight (pounds) 570.0 Shipping Weight (kilograms) 259.0 Catalog Page Number 105 Operator's Manual PDF Version

$21,300.07

-

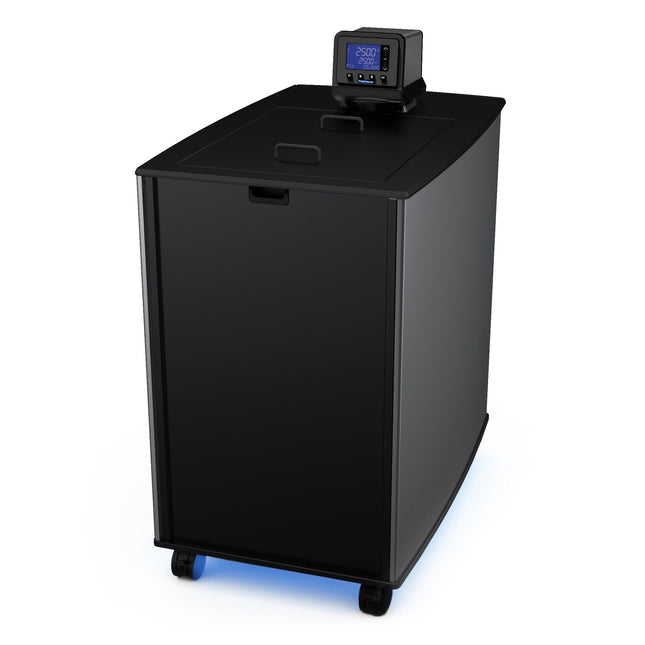

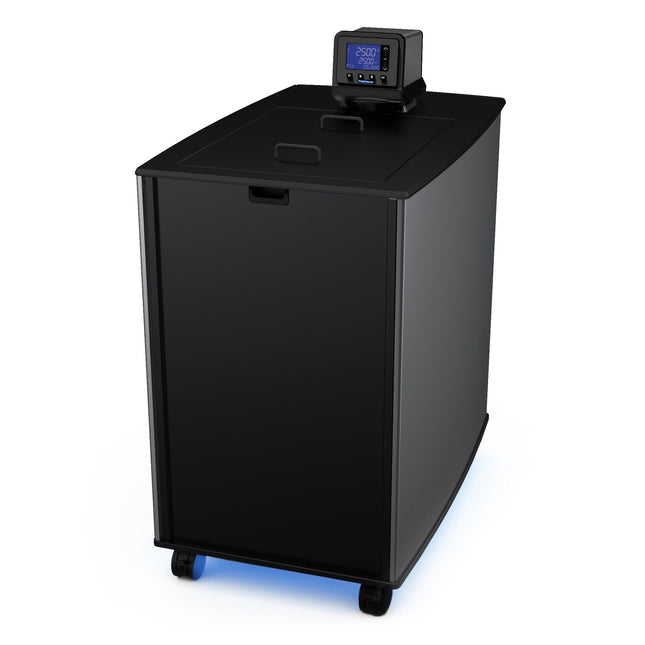

Polyscience Polyscience 45 Liter Advanced Digital Refrigerated Circulator (-25°C/135°C)

Polyscience 45 Liter Advanced Digital Refrigerated Circulator (-25°C/135°C) Specification Description -25, 45 L Ref. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C -25° to 135° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 54.9 x 39.8 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F -13° to 275° Working Temperature Range °C -25° to 135° Nominal Cooling Capacity @ +20C (W) 1400 Reservoir/Tank Material Stainless Steel Reservoir Capacity (gallons) 11.88 Reservoir Capacity (liters) 45 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 21.6 x 15.68 x 5.5 in Working Access (L x W x D) (cm) 54.9 x 39.8 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 35.8 x 22.4 x 42.1 in Overall Dimensions (L x W x H) (cm) 90.9 x 56.8 x 107 cm Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 180.0 Shipping Weight (kilograms) 81.5 Catalog Page Number 40-41 60 Hz Only Part Number AD45R-20-A13D Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 250 Cooling Capacity @ 0°C (W) 800 Cooling Capacity @ +20°C (W) 1400 Cooling Capacity @ +100°C (W) 1400 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 2200 Electrical Requirements (VAC/Hz/Ph/A) 208-230/60/1/13 Regulatory Approvals ETL Key Features: Intuitive 3.75" (9.5cm) display with touch-pad control 4 Languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$13,790.24 $9,713.39

-

Polyscience Polyscience 6100 Series 1 HP Chiller, Turbine Pump

Polyscience 6100 Series 1 HP Chiller, Turbine Pump Key Specifications: 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Key Features: Large, dual displays present temperature and pressure or flow rate simultaneously Compact, portable design takes up less floor space Cooling at ambient temperatures as high as 35C Powerful Turbine Pump User-adjusable temperature, pressure, and flow rate alarms Cool Command, WhisperCool Common Specifications: Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capcity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Dispplay Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Techonology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Tmeperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 60 Hz Only Part Number: 6160T21A130D Maximum Pressure (psi): 100 Maximum Pressure (bar): 6.90 Maximum Pressure Flow Rate (gpm): 3.50 Maximum Pressure Flow Rate (l/min): 13.2 Cooling Capacity @ +10C(W): 1925 Cooling Capacity @ +20C(W): 2900 Cooling Capacity @ +30C(W): 3103 Electrical Requirements (VAC/Hz/Ph/A): 230/60/1/12.2 Certifications Regulatory Approvals: TUV

$10,962.25

-

Polyscience Polyscience 7 Liter Heated Circulator

Polyscience 7 Liter Heated Circulator ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Description: 200, 7 L Htg. Circulator Controller Type: Advanced Digital Display: 3.75" Touch-Pad LCD Connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported: 4: French, German, Spanish, English Swivel 180 Rotating Controller: Yes Working Temperature Range °C: +10° to 200° Temperature Stability °C: ±0.01° Fluid Optimization/Specific Heat Tuning: Automatic and/or user-adjustable Temperature Calibration Capability: 1-point Working Access (L x W x D) (cm): 15.7 x 14.2 x 12.7 cm Pump Type: Pressure/Suction External Temperature Control Capability: Yes Flammability Class (DIN 12876-1): III (FL) Specifications Working Temperature Range °F Ambient + 20° to 392° Working Temperature Range °C Ambient +10° to 200° Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Coiling Coil Yes Over-Temperature Protection / Failsafe Heater Control Yes WhisperCool Environmental Control Technology Yes Low Liquid Level Protection Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 19.6 x 8.7 x 16.1 in Overall Dimensions (L x W x H) (cm) 49.9 x 22.1 x 40.9cm Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 42.0 Shipping Weight (kilograms) 19.0 60Hz Part Number AD07H200-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/10 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Operator's Manual

$4,081.01

-

Polyscience Polyscience 7 Liter Low Profile MX Refrigerated Circulator

Polyscience 7 Liter Low Profile MX Refrigerated Circulator Note: This item may carry up to a 4-6 week lead time. The Polyscience 7 Liter Low Profile MX Refrigerated Circulator is an more ergonomic version of the standard 7L Refrigerated Circulator. It is the ideal low temperature cooler for short path distillation and can also be used to heat jacketed bases and chill jacketed columns for small capacity extraction systems. Specification Description -20, 7 L Low Ref. Circulator Controller Type MX Display 3.75" Touch-Pad LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 23.2 x 16.2 x 17.3 in Overall Dimensions (L x W x H) (cm) 23.2 x 16.2 x 17.3 in Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX7LR-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$5,828.03

-

Polyscience Polyscience 7 Liter MX Heated Circulator

Polyscience 7 Liter MX Heated Circulator Key Specifications Description 135, 7 L Htg. Circulator Controller Type MX Display 3.25" LCD Languages Supported English Temperature Stability °C Ambient +10° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F Ambient + 20° to 275° Working Temperature Range °C Ambient +10° to 135° Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.1 Display Resolution (Read) 0.1 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Cooling Coil Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 19.6 x 8.7 x 17.2 in Overall Dimensions (L x W x H) (cm) 49.9 x 22.1 x 43.7 cm Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 36.0 Shipping Weight (kilograms) 16.3 Catalog Page Number 60-61 60 Hz Only Part Number MX07H135-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/10 Regulatory Approvals ETL Key features: Large, universal icon and English display On-screen prompts Single-point calibration capability Certifications Regulator Approvals: ETL Operator's Manual

$3,191.54

-

Polyscience Polyscience 7 Liter MX Refrigerated Circulator (-20°C to 135°C)

Polyscience 7 Liter MX Refrigerated Circulator (-20°C/135°C) Specification Description -20, 7 L Ref. Circulator Controller Type MX Display 3.25" LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 21.3 x 8.7 x 25.4 in Overall Dimensions (L x W x H) (cm) 54.1 x 22.1 x 64.5 cm Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX07R-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, Universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$5,689.27

-

Polyscience Polyscience 7 Liter Refrigerated Circulator, -40°C

Polyscience 7 Liter Refrigerated Circulator, -40°C ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Description: -40, 7 L Ref Circulator Controller Type: Advanced Digital Display: 3.75" Touch-Pad LCD Connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported: 4: French, German, Spanish, English Swivel 180 Rotating Controller: Yes Working Temperature Range °C: -40° to 200° Temperature Stability °C: ±0.01° Fluid Optimization/Specific Heat Tuning: Automatic and/or user-adjustable Temperature Calibration Capability: 1- point Working Access (L x W x D) (cm): 15.7 x 14.2 x 12.7 cm Pump Type: Pressure/Suction External Temperature Control Capability: Yes Flammability Class (DIN 12876-1): III (FL) Specifications Working Temperature Range °F -40° to 392° Working Temperature Range °C -40° to 200° Nominal Cooling Capacity @ +20C (W) 360 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock LidDock Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 21.3 x 8.7 x 24.3 in Overall Dimensions (L x W x H) (cm) 54.1 x 22.1 x 61.7 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 90.0 Shipping Weight (kilograms) 40.8 60Hz Part Number AD07R-40A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 115 Cooling Capacity @ 0°C (W) 250 Cooling Capacity @ +20°C (W) 360 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL

$7,283.65

-

Polyscience Polyscience 7 Liter Standard Digital Refrigerated Circulator (-20°C/170°C)

Polyscience 7 Liter Standard Digital Refrigerated Circulator (-20°C/170°C) ***Note: This item has a possible 2-3 week lead time depending on stock availability.*** Specification Description -20, 7 L Ref. Circulator Controller Type Standard Digital Display 3.75" Touch-Pad LCD Connectivity RS232 Swivel 180 Rotating Controller Yes Working Temperature Range °C -20° to 170° Temperature Stability °C ±0.04° Fluid Optimization/Specific Heat Tuning Automatic Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 338° Working Temperature Range °C -20° to 170° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Reservoir Liquid Level Indicator Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.08° Temperature Stability °C ±0.04° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.1 Display Resolution (Read) 0.1 Pump Type Pressure Pump Speed Two Process Connections 1/4" (F) NPT Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 21.3 x 8.7 x 24.3 in Overall Dimensions (L x W x H) (cm) 54.1 x 22.1 x 61.7 cm Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 90.0 Shipping Weight (kilograms) 40.8 Catalog Page Number 42-43 60 Hz Only Part Number SD07R-20-A11B Maximum Pressure (psi) 3.5 Maximum Pressure (bar) 0.24 Maximum Pressure Flow Rate (gpm) 2.90 Maximum Pressure Flow Rate (l/min) 11.0 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, universal icon and English display Swivel 180™ Rotating Controller On-board connectivity: RS-232 serial output On-screen prompts Automatic performance optimization Single-point calibration capability Operator's Manual

$5,495.00

-

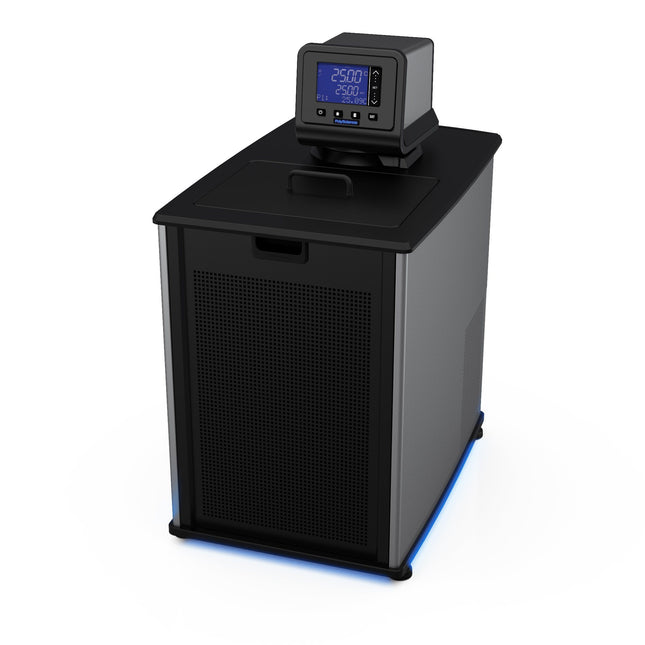

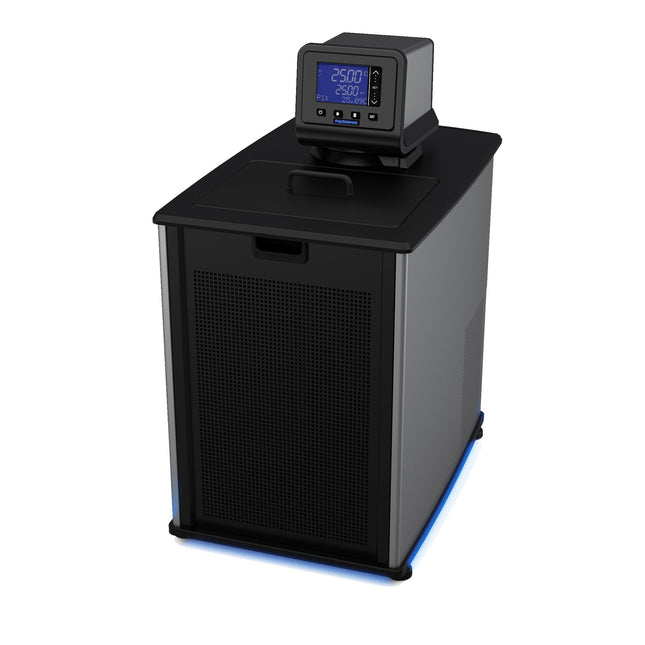

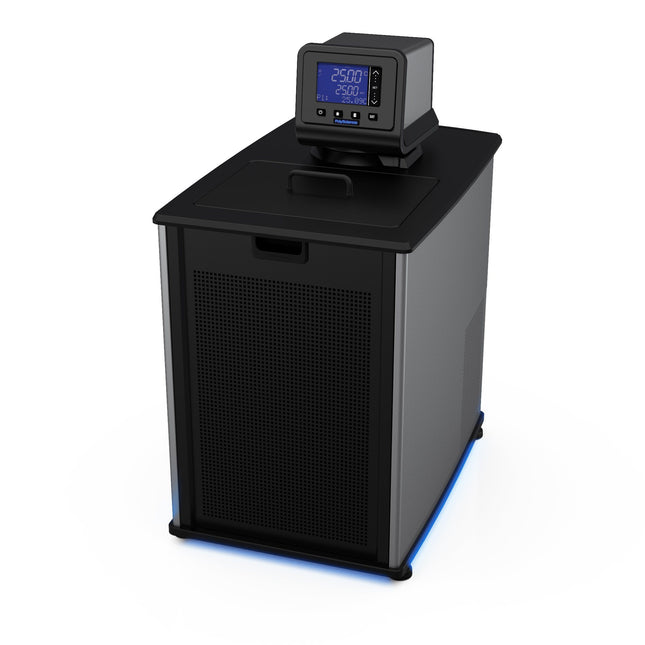

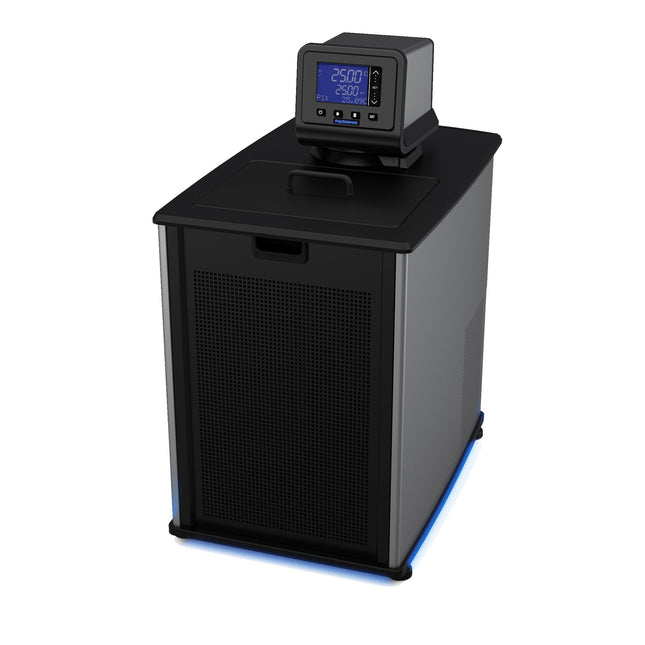

Polyscience Polyscience DuraChill 1.5HP Chiller, Turbine Pump

Polyscience DuraChill 1.5HP Chiller, Turbine Pump Note: This item has a lead time of 2-3 weeks depending on stock availability Specification Description 1.5 HP Chiller, Turbine Pump; Air-Cooled Display LED Connectivity Optional: RS232, RS485 Working Temperature Range °C 5° to 35° Temperature Stability °C ±0.5° Temperature Calibration Capability 1-point Pump Type Turbine Working Temperature Range °F 41° to 95° Working Temperature Range °C 5° to 35° Reservoir Capacity (gallons) 3.5 Reservoir Capacity (liters) 13.25 Reservoir/Tank Material Polyethylene Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Cleanable Fluid Filter Yes Temperature Stability °F ±0.9° Temperature Stability °C ±0.5° Display LED Display Resolution (Read) 0.01 Pump Type Turbine Process Connections 1/2" (F) NPT Over-Temperature Protection / Failsafe Heater Control Yes Reservoir Liquid Level Indicator Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 30.5 x 19 x 26 in Overall Dimensions (L x W x H) (cm) 78 x 48 x 66 cm Compressor Size (HP) 1.5 Refrigerant R134a Shipping Weight (pounds) 340.0 Shipping Weight (kilograms) 154.0 Catalog Page Number 104 60 Hz Only Part Number 6860T56A270D Maximum Pressure (psi) 100.0 Maximum Pressure (bar) 6.90 Maximum Pressure Flow Rate (gpm) 11.00 Maximum Pressure Flow Rate (l/min) 41.6 Cooling Capacity @ +10°C (W) 4420 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 5200 Cooling Capacity @ +30°C (W) 5980 Heater Wattage 1000 Electrical Requirements (VAC/Hz/Ph/A) 230/60/1/23.1 Regulatory Approvals TUV Key specifications: High capacity cooling for lasers, electron microscopes, and other laboratory applications Small footprint conserves floor space Displays temperature and pressure or flow rate simultaneously User-adjustable temperature, pressure, and flow rate alarms Simple operation and maintenance Air- or water-cooled Positive displacement (PD) or turbine (T) pump; other pump options also available Certifications Regulatory Approvals: TUV Operator's Manual

$15,861.96

-

Polyscience Polyscience Durachill Chiller

Polyscience Durachill Chiller; 4.2 L; 208/230 V PolyScience CA10A3T1-41AA1N Offers Features: Large, full-color touchscreen display with intuitive interface and support for five different languages Home screen simultaneously displays set temperature, actual temperature, fluid pressure, fluid level, air filter status and timer Self-changing air filter system eliminates preventative maintenance by automatically changing the filter media at user-definable intervals Continuous fluid level monitoring protects pump and prevents freezing Whispercool® noise reduction system reduces operating noise levels to the almost imperceptible levels while maintaining optimal cooling performance Reduced global warming potential through a highly optimized refrigeration system design that greatly reduces the amount of refrigerant gas needed in the chiller and allows for migration to natural refrigerants that have little or no global warming potential Self-diagnostic system compares the chiller's functionality to its operating state the day it was built to minimize operating downtime and unnecessary service calls Compact, portable design takes up less floor space Cooling at ambient temperatures as high as 30°C Components are recyclable and meet or exceed global environmental standards UV Light Biological Growth Inhibitor System eliminates the need for algaecides User-adjustable temperature, pressure, and flow rate alarms Heat up to 70°C, without additional options Front fill reservoir access Externally accessible adjustable pressure regulator valve Full color touch screen display The color touch screen display gives you all the information you need at a glance. The screen will display continuous status of set temperature, actual temperature, reservoir fill level and output pressure as well as the status of your air filter. System messages are provided in easy to read text instead of confusing error codes. Dynamic self-changing filter Preprogrammed to change its own air filter once a month for a two year period, and the change interval can be adjusted to suit your operating environment. This will dramatically reduce downtime and unnecessary service calls and relieve you of the burden of preventative maintenance on your chiller. UV light biological growth inhibitor The UV Light Biological Growth Inhibitor will continuously control biological growth in the fluid path without the need to add chemical growth inhibitors and preventing algicides from being released into the world's waterways. Front fill reservoir The chiller offers a conveniently located front fill reservoir. You no longer have to go to the back of the chiller top open to fill the reservoir. It has the fill port in the front, making it easy to access, avoiding spills and saving time. Continuous liquid level monitoring Because pump seals will fail in as little as 30 seconds of being run dry, the chiller includes a state-of-the-art capacitance liquid level sensor to protect the pump from premature failure. If the fluid level becomes low, the chiller will give you visual and audible alarms. If the fluid level reaches a point where there's a risk of pulling air into the pump, it will shut the chiller down and present another alarm. Whispercool® noise reduction This high-performance chiller utilizes noise reduction system. The Whispercool® system evaluates the demand for cooling from the application then slows the fan speed to the minimum necessary to achieve control point, making the chiller extremely quiet while maintaining optimal temperature control at the same time. Applications Heat removal Specifications Cooling Capacity At 20°C: 2.9 kWAt 10°C: 1.93 kWAt 0°C: 1 kW Fluid Temperature Range 14 to 158°F (-10 to 70°C) Temperature Stability ±0.1°C Displayable Units Temperature: °C or °FPressure: psi or kPa Pump Inlet and Outlet ½" female NPT Connectivity RS-232, USB Serial Port Emulation, USB TMC, Dry Contact On/Off/Status Selectable Operating Languages English, Spanish, French, German, Mandarin Self-Changing Air Filter Yes UV Biological Growth Inhibitor Yes Ambient Air Temperature Tracking Yes Pump Pressure Range 20 to 90 psi (138 to 689 kPa) Maximum Pump Flow Rate 3.5 gpm (13.2 lpm) Power Requirements 230 V, 60 Hz, 13.5 A Dimensions 33 x 22 x 33" (84 x 56 x 84 cm) Weight 177 lbs (80.3 kg) Data sheet Manual

$11,527.02

-

Polyscience Polyscience IP-100 Low Temperature Cooler, 3" Rigid Coil Probe

Polyscience IP-100 Low Temperature Cooler, 3" Rigid Coil Probe ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Key Specifications Description Immersion Probe-100, 3" Rigid Coil Display Temperature Working Temperature Range °C -100° to -60° Working Temperature Range °F -148° to -76° Working Temperature Range °C -100° to -60° Temperature Control (°F) Fixed at -148° Temperature Control (°C) Fixed at -100°C Cleanable Air Filter Yes Display Temperature Maximum Ambient Temperature °F 86° Maximum Ambient Temperature °C 30° Overall Dimensions (L x W x H) (in) 20.1 x 15 x 22.3 in Overall Dimensions (L x W x H) (cm) 51.1 x 38.1 x 56.6 cm Refrigerant R404A & R508B Immersion Probe Type Rigid Coil Probe Diameter (inches) 3 Probe Diameter (cm) 7.62 Probe Length (inches) Coil: 9 / Exposed: 17 Probe Length (cm) Coil: 22.9 / Exposed: 43.2 Flexible Hose Diameter (inches) 2.83 Flexible Hose Diameter (cm) 7.14 Flexible Hose Length (feet) 6 Flexible Hose Length (m) 1.83 Shipping Weight (pounds) 162.0 Shipping Weight (kilograms) 73.5 Catalog Page Number 114-115 60 Hz Only Part Number P10N6A101B Cooling Capacity @ -100°C (W) 0 Cooling Capacity @ -80°C (W) 35 Cooling Capacity @ -65°C (W) 85 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/11.5 Key Features: Continuous cooling to temperatures as low as -100C Designed to run at maximum cooling An economical alternative to dry ice or liquid nitrogen Excellent for trapping applications, freeze drying, and rapidly cooling small volumes of liquids Operator's Manual

$8,452.03

-

Polyscience Polyscience IP-60 Low Temperature Cooler, 1.5" Rigid Coil Probe

Polyscience IP-60 Low Temperature Cooler, 1.5" Rigid Coil Probe ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Specification Description Immerson Probe-60, 1.5" Rigid Coil Working Temperature Range °C -60° to -20° Temperature Control (°C) Fixed at -60° Working Temperature Range °F -76° to -4° Working Temperature Range °C -60° to -20° Temperature Control (°F) Fixed at -76° Temperature Control (°C) Fixed at -60° Maximum Ambient Temperature °F 86° Maximum Ambient Temperature °C 30° Overall Dimensions (L x W x H) (inches) 11 x 10 x 9 in Overall Dimensions (L x W x H) (cm) 27.9 x 25.4 x 22.9 cm Refrigerant R404A & R508B Immersion Probe Type Rigid Coil Probe Diameter (inches) 1.5 Probe Diameter (cm) 3.81 Probe Length (inches) Coil: 4 / Exposed: 15 Probe Length (cm) Coil: 10.2 / Exposed: 38.1 Flexible Hose Diameter (inches) 1.5 Flexible Hose Diameter (cm) 3.81 Flexible Hose Length (feet) 4 Flexible Hose Length (m) 1.22 Shipping Weight (pounds) 49.0 Shipping Weight (kilograms) 22.0 Catalog Page Number 114-115 60 Hz Only Part Number P60N2A101B Cooling Capacity @ -60°C (W) 0 Cooling Capacity @ -40°C (W) 100 Cooling Capacity @ -30°C (W) 125 Cooling Capacity @ -20°C (W) 150 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/5 Key Features: Continuous cooling to temperatures as low as -60C Designed to run at maximum cooling An economic alternative to dry ice or liquid nitrogen Excellent for trapping applications, freeze drying, and rapidly cooling small volumes of liquids Operator's Manual

$3,260.92

-

Polyscience Polyscience LS 1/2HP Chiller, Centrifugal Pump

Polyscience LS 1/2HP Chiller, Centrifugal Pump Note: This item has a lead time of 2-3 weeks depending on stock availability. Key Specifications Description LS Series 1/2 HP Benchtop Chiller, Turbine Pump; 43.4 psi; 9.8 l/min Display LED Connectivity Optional: RS232 Working Temperature Range °C -20° to 40° Temperature Stability °C ±0.1° Temperature Calibration Capability 1-point Pump Type Turbine Working Temperature Range °F -4° to 104° Working Temperature Range °C -20° to 40° Reservoir Capacity (gallons) 0.7 Reservoir Capacity (liters) 2.65 Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Temperature Stability °F ±0.2° Temperature Stability °C ±0.1° Display LED Pump Type Centrifugal Pump Speed Constant, Single Speed Process Connections 1/2" (F) NPT Over-Temperature Protection / Failsafe Heater Control Yes Reservoir Liquid Level Indicator Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 23.9 x 10 x 19 in Overall Dimensions (L x W x H) (cm) 60.7 x 25.4 x 48.3 cm Compressor Size (HP) 1/2 Refrigerant R452A Shipping Weight (pounds) 102.0 Shipping Weight (kilograms) 46.3 Catalog Page Number 98-99 60 Hz Only Part Number LS51MX1A110C Maximum Pressure (psi) 43.4 Maximum Pressure (bar) 3.00 Maximum Pressure Flow Rate (gpm) 2.60 Maximum Pressure Flow Rate (l/min) 9.8 Cooling Capacity @ -20°C (W) 150 Cooling Capacity @ -10°C (W) 345 Cooling Capacity @ -5°C (W) 395 Cooling Capacity @ 0°C (W) 540 Cooling Capacity @ +10°C (W) 790 Cooling Capacity @ +20°C (W) 900 Cooling Capacity @ +30°C (W) 1020 Cooling Capacity @ +40°C (W) 1140 Included Hardware Two sets of Inlet/Outlet Adapters: ½ inch male NPT, 5/8 inch male NPT Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals TUV Key Features: Optimized for high performance at low temperatures Capable of cooling multiple rotary evaporators WhisperCool Environmental Control System Large, easy to read LED display Space-saving design Cooling at ambient temperatures as high as 35C Low flow shutoff and alarm, high and low temperature alarms Simple setup, operation, and maintenance Centrifugal or turbine pump Fluid level indicator RS232 communication and external water filter optional Regulator Approvals: TUV Approvals CE Approvals Operators Manual

$6,707.79

-

Polyscience Polyscience Model 3370 Liquid-to-Air Cooler, 1/3 HP Turbine Pump

Polyscience Model 3370 Liquid-to-Air Cooler, 1/3 HP Turbine Pump ***Note: This item may have a lead time of 2-3 weeks depending on stock availability.*** Key Features An economical solution for applications where cooling fluid temperature is higher than ambient and temperature control is not required Quiet liquid-to-air cooling Positive displacement or turbine pump Built-in low liquid level indicator Specifications Description Liquid-to-Air Cooler, Turbine Pump Working Temperature Range °C Ambient +5° to 70°C Pump Type Turbine Working Temperature Range °F Ambient +10° to 158° Working Temperature Range °C Ambient +5° to 70°C Reservoir Capacity (gallons) 1.11 Reservoir Capacity (liters) 4.2 Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Cleanable Fluid Filter Yes Pump Type Turbine Pump Speed Constant, Single Speed Process Connections 1/2" (F) NPT Reservoir Liquid Level Indicator Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 20.5 x 15 x 22.3 in Overall Dimensions (L x W x H) (cm) 52 x 38.1 x 54.6 cm Shipping Weight (pounds) 132.0 Shipping Weight (kilograms) 59.9 Catalog Page Number 107 60 Hz Only Part Number 3370TBA11B Maximum Pressure (psi) 62.0 Maximum Pressure (bar) 4.30 Maximum Pressure Flow Rate (gpm) 5.40 Maximum Pressure Flow Rate (l/min) 20.5 Cooling Capacity @ 20°C (W) 500 based on 3°C ΔT 1000 based on 6°C ΔT 2000 based on 12°C ΔT 3000 based on 18°C ΔT 4000 based on 24°C ΔT ΔT = (Process water temperature - ambient air temperature) Included Hardware Two sets of Inlet/Outlet Adapters: ½ inch male NPT, 5/8 inch male NPT Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/5.5 Regulatory Approvals TUV Operator's Manual PDF Version

$4,286.38

-

Porcelain Buchner Funnel

Porcelain Buchner Funnel Buchner funnel Porcelain Labware is used in the chemistry laboratory. It has exceptional resistance to all reagents except hydrofluoric acid and is highly resistant to thermal shock while having a very low coefficient of expansion. To prevent thermal stress cracks on porcelain ware do not exceed a heating/cooling rate of 200°C per hour. To prolong the life of porcelain products: · Follow gradual heating/cooling rates · Use an oven or hot plate and an intermediate step when quicker heating/cooling rates are required · Avoid contact of heated ware with a cold surface · Carefully check labware prior to each use and do not use any product that appears defective With straight sides above the perforated plate. Thick stem. Sizes Available: 1000ml - 5.5" (~140mm) Diameter 2000ml - 7-3/8" (~187mm) Diameter

$76.32 - $117.95

-

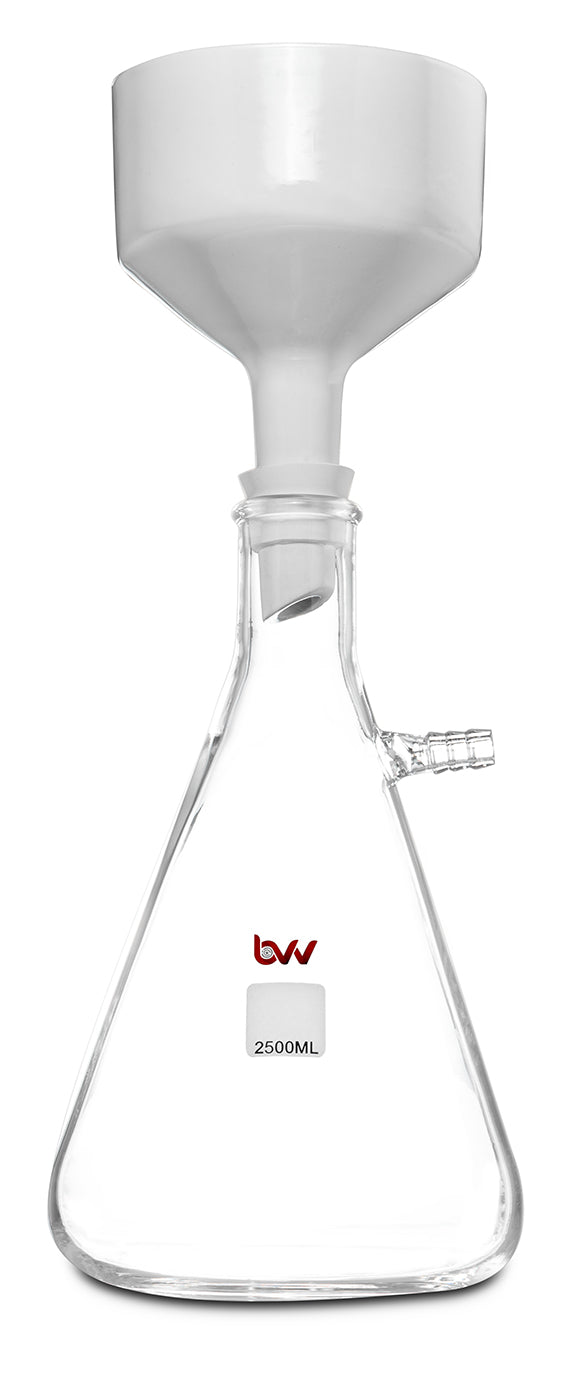

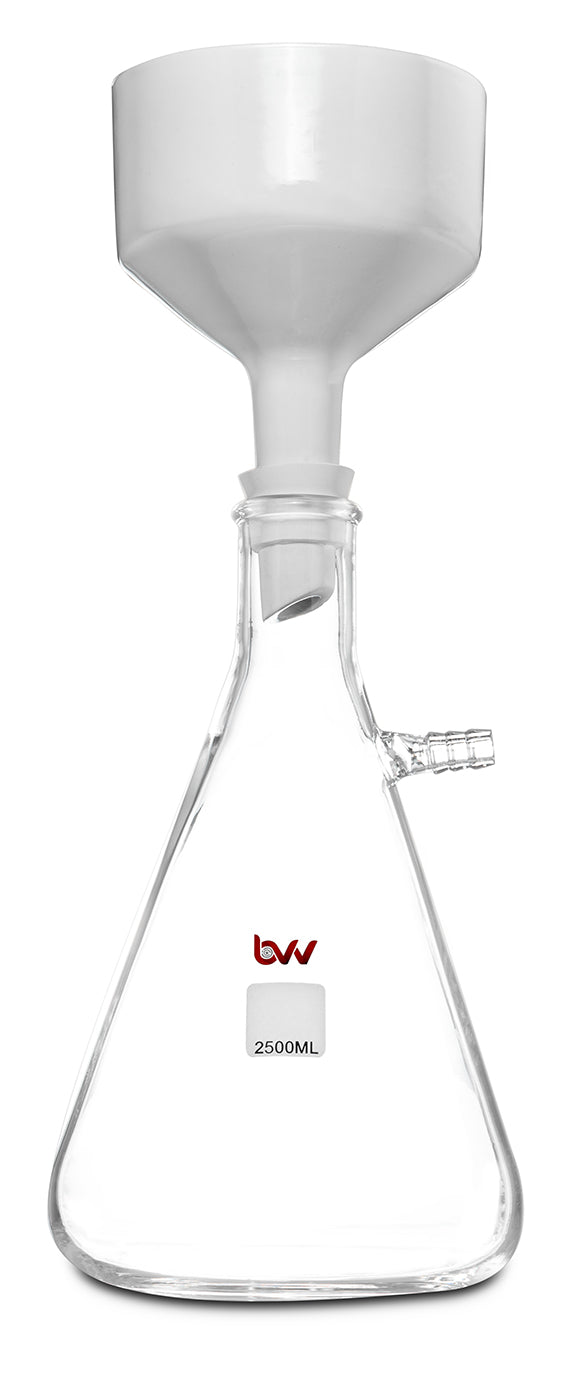

Porcelain Buchner Funnel Filtration Kit

Porcelain Buchner Funnel Filtration Kit This BVV™ Porcelain Buchner Funnel Filtration Kit was designed for continuous filtration of oils by using our large diameter porcelain Buchner funnel by increasing filtration area. Depending on the capacity needed you may select the size of the conical flask through a dropdown for 2500ml or 5000ml capacities. This Kit Includes the Following: (1) 1.5 Gallon Cold Trap with 1/4" Barbs (1) Rubber Cones, Set of 9 (1) Porcelain Buchner Funnel - 1000ml(When 2500ml Conical Flask is selected) or 2000ml(When 5000ml Conical Flask is selected) (1) BVV4D 4CFM Two Stage Vacuum Pump (1) Conical Flask with Filtering Side Arm - 2500ml or 5000ml (5') Gum Rubber Vacuum Tubing (1) HVAC hose (1) Ashless Filter Paper - 180mm Qualitative - Grade 1

$485.67 - $728.50

-

Porcelain Buchner Funnel Kit

This porcelain buchner funnel kit includes a 3.3 borosilicate non-jointed conical flask with side port hose barb, porcelain buchner funnel in either 1000 or 2000ml and a 9 piece rubber cones set to create the seal between the flask and the funnel. Each kits includes the following: 1000ML: (1) - 1000ml Porcelain Buchner Funnel (1) - 2500ml Conical Flask Filtering with Internal Side Arm (1) - Rubber Cones Set of 9 2000ML: (1) - 2000ml Porcelain Buchner Funnel (1) - 5000ml Conical Flask Filtering with Internal Side Arm (1) - Rubber Cones Set of 9

$187.33 - $235.90

-

Portable Butane Leak Detector (C4H10)

Portable Butane Leak Detector C4H10 (Comes with 30 Day Limited warranty) Product Features: Handheld, industry use, high sensitivity and accuracy Intrinsically safe, Ex sign is Exhibit Rugged ABS+PC case, heavy duty, crash resistant High-capacity chip, 4 layers PCB board Visual & audible alarm Low battery alarm Charging dock, easier access to recharging Energy saving LED screen shows real time concentration External air sampling pump is available for gas leak detection Leather case is provided Usage: The gas detection instruments we designed are widely used in petrochemical, municipal environmental protection, coal mine, residential places, and other natural and wide ranges of industrial environments. Technical Parameter: Gas detected - Butane (Infrared Sensor C4H10 IR Measuring range - (0.00~5.00)%vol, (0~100)%vol Resolution ratio - 0.01%vol Sensor - Infrared Sensor, Made in UK Sensor lifetime - ≥5 year Response time - ≤45s(T90) Alarms - Audible--buzzer with ≥75dB audible Visible--flashing red LED, ≥20m visible Alarm point - Fully adjustable Continuous working time - >16h Working current - < 1mA ( without backlight) Working temperature - -25℃~+55℃, short time: -40℃~+55℃ Display - Liquid crystal display (LCD) Battery model - PL123450, 3.7V/1500mA Charging time - 4-5 hours Dust and water resistance - IP65 Size & Weight - 105*54*32mm/450g Included in the box: Charging adapter calibration cap calibration gas hose hanging cord leather case manual

$374.66

-

Postal Scale 110lb Max, Ounces, Grams, Lbs, Kg

The SF-890 is a postal scale that comes with a detached digital display for easy reading of large items. Batteries included 2xAA, as well as a wall plug to power the unit. This scale works best for items over 1lb. Low weight items (ie. 1-10grams is difficult to accurately detect)

$55.51 $44.40

-

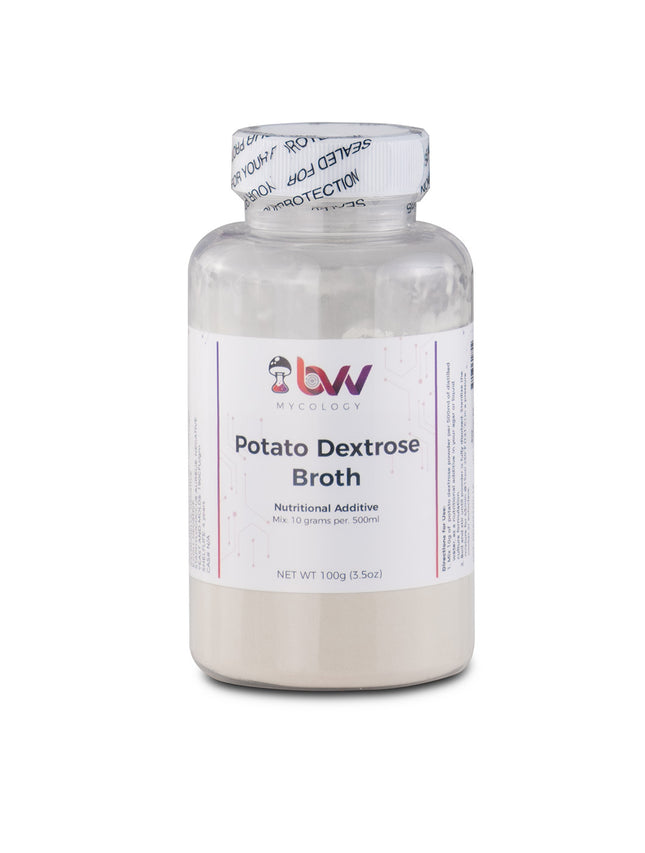

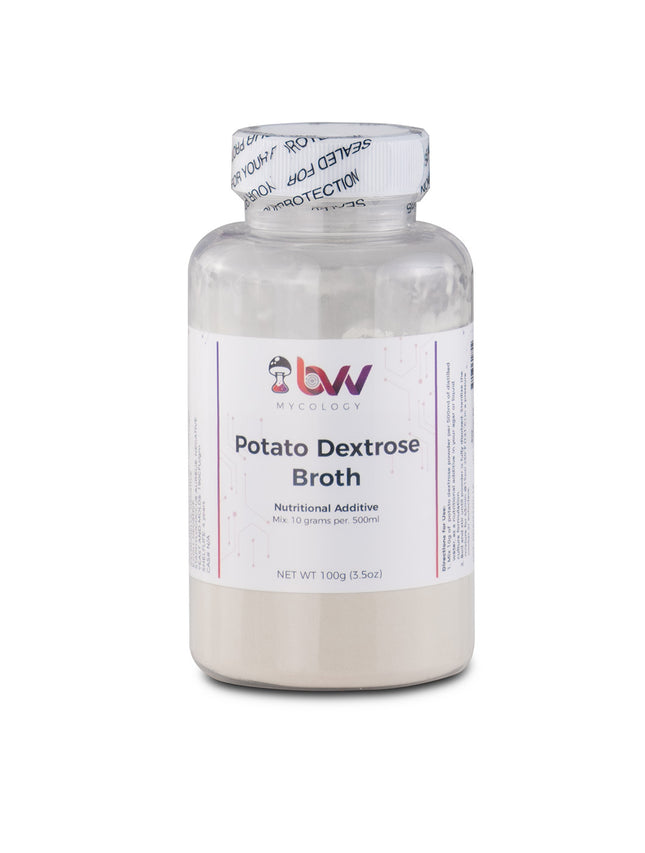

Potato Dextrose Broth for Mushrooms Mycology

Potato Dextrose Broth For Mushroom Mycology Bacteriological GradeBest for Vigorous Mycelia Growth Potato Dextrose Broth (PDB) is a liquid microbiological growth medium made from potato infusion and dextrose, used to cultivate and isolate yeasts and molds from food products and other samples. Its low pH inhibits bacterial growth, while the rich potato and dextrose components provide nutrients for fungal sporulation and pigment production. STORAGE: Cool dry conditions, sealed original package Mix: Mix: 1 gram per. 500ml Directions for Use: 1. Mix 10g of Potato Dextrose Broth per 500ml of liquid culture or agar recipe for vigorous mycelia growth. 2. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave.

$16.65 - $73.54

-

Pre-Built 50L Stainless Steel Jacketed Reactor

The 50L Stainless Steel Jacketed Reactor is designed for use with positive pressure. Glass reactors are only able to handle negative pressures which limits their usability. The vessel jacket can be used to circulate chilling fluid or as vacuum insulation. The vessel wild hold 50L (13 gallons) of liquid or 10 lbs of botanical material and the outer jacket capacity is 14.22L or 3.76 gallons of fluid. Reaction Vessel Applications: Ethanol Extraction Winterization Filtration Pre-Chilling Solvent Mixing & Homogenizing Key Features: Vessel Rated to 100 PSI MAX 1/2" MJIC Connection 1/4" MJIC Connection High-Pressure Clamps Minimal footprint 12" Tri-Clamp top ferrule for easy loading and unloading Lockable casters for mobility 6" Tri-Clamp bottom ferrule for easy loading and unloading Modular Tri-Clamp design Polycarbonate sight glasses for easy viewing 1/2" barb connection on the jacket Alcohol resistant silicone gaskets. Low temperature model comes with PTFE gaskets and Borosilicate sight glasses.

$2,879.33

-

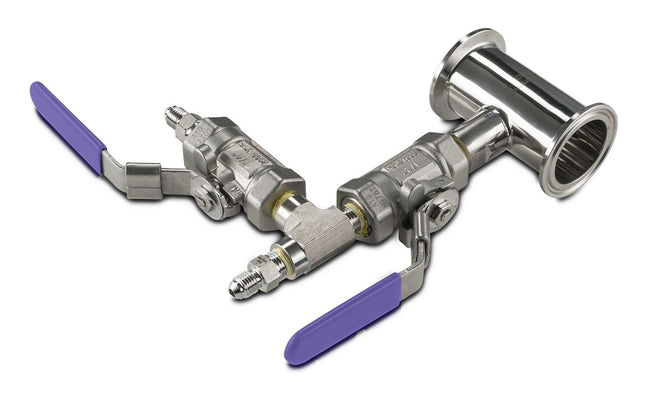

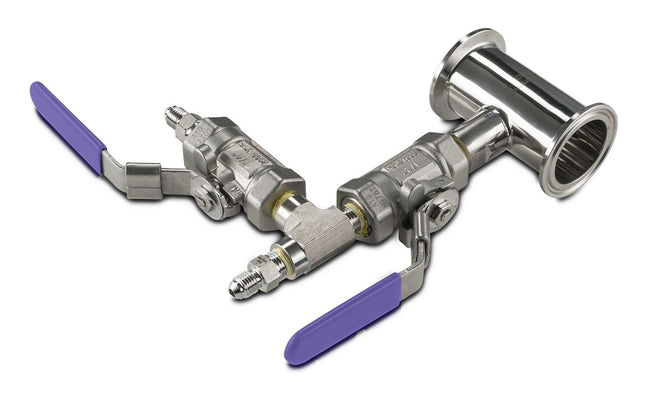

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves (This part is fully assembled and Nitrogen Tested for Leaks at BVV™) This BVV™ BIFLOW Manifold is fully assembled and nitrogen tested for leaks at our warehouse. This manifold comes with 2 BVV 316SS Full Bore Valves with (2)1/4" 37° JIC Flares. This manifold is made out of 304 stainless steel with a Tri-Clamp end connection on either side. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel 1.5" or 2" Tri-Clamp Connections Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" 37° JIC Tri-Clamp Size(s) Selectable through Dropdown Nitrogen Tested Yes

$277.53 - $285.85

-

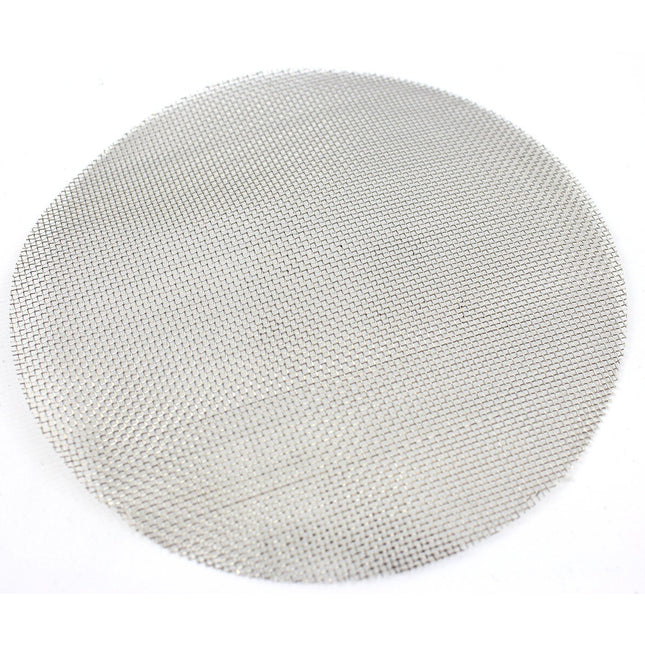

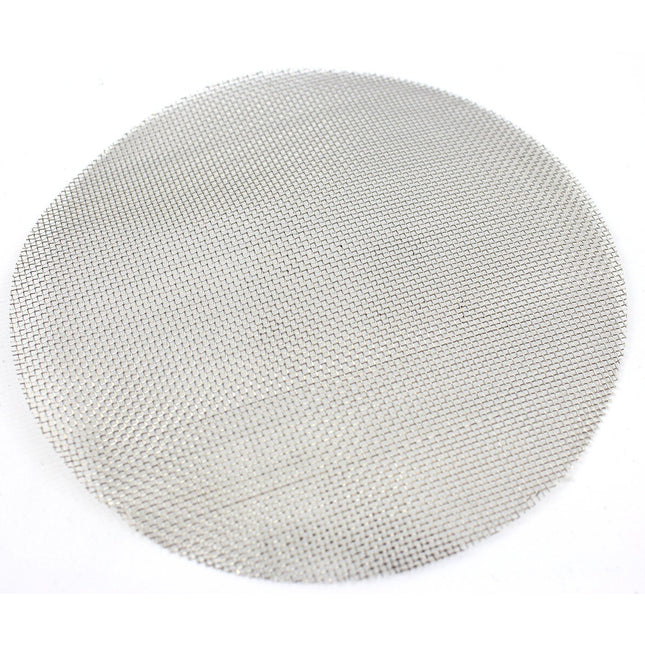

Pre-Cut Stainless Steel Mesh for Tri-Clamp Filter Plates 100 Mesh (150 Micron)

Pre-Cut Stainless Steel Mesh for Tri-Clamp/Tri-Clover Filter Plates 100 Mesh (150 Micron) These Stainless Steel Mesh are pre-cut for convenience to fit inside Tri-Clamp filter plates or spools. They offer great filtration and are very durable and reusable. Additionally, these 150-Micron filter plates will protect and act as a pre-filter for finer mesh screens or filter paper which will prevent the finer micron filter media from becoming clogged. Sizes Available: 1.5" Tri-Clamp 100 Mesh (150 Micron) 2" Tri-Clamp 100 Mesh (150 Micron) 3" Tri-Clamp 100 Mesh (150 Micron) 4" Tri-Clamp 100 Mesh (150 Micron) 6" Tri-Clamp 100 Mesh (150 Micron) 8" Tri-Clamp 100 Mesh (150 Micron) Specifications Material 304 Stainless Steel Mesh Level 100 (150 Micron) *Compression Ring and Filter Plate NOT Included.

$11.79 - $45.79

-

Premium Vacuum Pump Oil

Premium Vacuum Pump Oil For Maximum performance and pump efficiency, change the oil after every evacuation. After evacuation, oil contains contaminants which limit pump efficiency. Premium vacuum pump oil can be used in any vacuum pump to maintain and prolong the life of the pump. Drain immediately after evacuation while pump is warm. Slowly add oil to top of "oil level" line. If oil is to low, you will hear the exhaust baffle chatter. If oil level is too high, excess oil will be blown out of the exhaust. Non detergent-Extra Pure-Hydroprocessed-ISO 400 BVV Vacuum Pump Oil Certificate of Analysis COA BVV Vacuum Pump Oil Safety Data Sheet SDS

$19.43 - $1,318.25

-

The Press Club Press Club’s 100% Aluminum Pre-Press Mold

PRE-PRESS MOLD The Press Club 100% aluminum pre-press molds help you quickly condense your start material before pressing. Pre-press molds will not only save you time but will help you achieve more uniform results and increase yields. 1.5" x 2.5" This 1.5" x 2.5" pollen press creates a circular puck (approximately the size of a quarter) that fits perfectly inside a bag. Made in the USA. 2" x 4" This 2" x 4" pre-press mold creates a rectangular slab that that fits perfectly inside a 2" x 4" bag or larger. Made in the USA. 2" x 9" This 2" x 9" pre-press mold creates a rectangular slab that that fits perfectly inside a 2" x 9" bag or larger. Made in the USA. 2.5" x 2.5" This 2.5" x 2.5" mold creates a square slab that fits perfectly inside a 2.5" x 4.5" rosin bag. Made in the USA. 2.5" x 4.5" This 2.5" x 4.5" pre-press mold creates a rectangular slab that that fits perfectly inside a 2.5" x 4.5" bag or larger. Made in the USA. 2.5" x 9" This 2.5" x 9" pre-press mold creates a rectangular slab that that fits perfectly inside a 2.5" x 9" bag or larger. Made in the USA. 3" x 5" This 3" x 5" mold creates a rectangular slab that fits perfectly inside a 3" x 6" filter bag. Made in the USA. 4" x 7" This 4" x 7" pre-press mold creates a rectangular slab that that fits perfectly inside a 4" x 7" bag or larger. Made in the USA.

$83.19 - $235.83

-

Pressure Filtration System - 6 x 28

This filter system is designed for high flow rates to filter unwanted precipitates from your oleoresin. The housing provides full enclosure of your filter bags, which are fully supported by the strainer basket within the housing to prevent blowouts. Pressure and high flow rates may be applied to get the fastest flow through filter bags. Using the housing allows full exhaustion of a bag prior to changing it without the sacrifice in filtering time.These filter bag housings use an eye-bolt clamp style to allow for high pressure without leakage, while still maintaining an easy to remove cover. When one filter bag gets filled, it can easily be swapped out by removing the lid while not under pressure and pulling the old bag out. The main seal on the housing is Buna-n rubber. The liquid pump is of 316 Stainless Steel Construction with PTFE seals and runs on compressed air or nitrogen. Built options Include: 1x 304 Stainless Steel Filter Bag Housing 1x 304 Stainless Steel Basket 1x 304 Stainless Steel Displacement Cylinder With Pump options Include: 1x 304 Stainless Steel Filter Bag Housing 1x 304 Stainless Steel Basket 1x 304 Stainless Steel Displacement Cylinder 1x 316 Stainless Steel Liquid pump Connecting hose or hardline tubing 4x Nomex Filter Bags (1μm, 5μm, 25μm, and 100μm) Specifications PFS-790-15 PFS-790-45 Flow Rate (GPM) ≤15 ≤45 Max Pressure (PSI) 100 @28 CFM Volume (in^3) 790 Working Temperature (°C) -40 - 100 Air Hose Connection ¼” JIC Flare ½” JIC Flare Filter Bag Housing Dimensions (LxWxH) 14” x 11” x 41” Filter Bag Trade Size #8 Included PVC Hose size ID ¾” 1” *This unit requires an air compressor for operation (not included)

$1,283.55 - $12,488.64

-

Pressure-Relief Valves for Cryogenic Liquids

Pressure-Relief Valves for Cryogenic Liquids Valve Function Pressure Relief For Use With Liquid Carbon Dioxide, Liquid Nitrogen, Liquid Oxygen Activation Pressure Driven Inlet Pipe Size 1/4 Connection Type Pipe Pipe Connection Type Threaded Connection NPT Male Location Bottom Maximum Pressure 600 psi Relief Port Thread Size 3/4"-20 Connection Type Pipe Pipe Connection Type Threaded Connection UNEF Female Location Top Set Pressure Accuracy ±5% Set Pressure Configuration Nonadjustable Temperature Range -320° to 165° F Shape Straight Overall Height 2 5/8" Material Body Brass Valve Type Relief Flow Coefficient (Cv) Not Rated Specifications Met CGA G-4.1 RoHS RoHS 3 (2015/863/EU) compliant with exemption 6(c) - Lead in copper alloy REACH Not Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 848140.0000 ECCN EAR99 Cleaned and bagged to meet CGA G-4.1 for oxygen service and other high purity applications, these valves are built to withstand the extreme cold of liquid carbon dioxide, liquid nitrogen, and liquid oxygen. They begin opening at the set pressure and fully open at about 10% over the set pressure. Valves begin closing as pressure drops and fully close when the system pressure is restored below the set pressure. Set pressure is not adjustable. Valves are not intended for direct contact with cryogenic liquids. Risers (sold separately) are required to convert cryogenic liquids into gases before they contact the valve. 3/8 NPT valve requires a 1/2 NPT × 3/8 NPT bushing when using a riser.

$166.52 - $208.14

-

Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump

Brand 14.1CFM Two Stage Pro Series This is the BVV™ Brand 14.1CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 14.1CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 14.1CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Weight: 38KG / 84lbs Recommended oil: Ultragrade 19 CE Compliance: Yes Warranty 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,497.73 $1,942.68

-

Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.5mtorr micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.5mtorr Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2.3L/2.4 quarts Working Temperature: 5C to 40C Unit Weight: 41KG / 90lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty: 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,122.16 $2,567.11

-

Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump

Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 35.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 35.3CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with KF40 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 220VAC - Note this pump does not come with a plug and must be wired manually. Pumping Rate: 35.3CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF40/NW40 Flange Oil Volume: 4.5L/4.76 quarts Working Temperature: 5C to 40C Unit Weight: 68KG / 150lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty 2 year limited warranty Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$6,660.61

-

Pro Series High Pressure Clamps

Pro Series High Pressure Clamps These are the Pro Series High Pressure Clamps for Heavy Duty Applications. These clamps are completely re-designed to be stronger and more industrial to last longer and stand up to higher pressure applications. The Internal flange of the clamp is much more precise offering better dispersion of pressure on the sealing face of the gasket which allows to the system to seal without having to overtighten the clamps. Sizes Available: 1.5" High Pressure Clamp 2" High Pressure Clamp 3" High Pressure Clamp 4" High Pressure Clamp 6" High Pressure Clamp 8" High Pressure Clamp 10" High Pressure Clamp 12" High Pressure Clamp Specifications: Hinge Type: Bolted Material: 304 Stainless Steel Connection Type: Tri-Clamp Nut Size: 5/8" for All Clamp Sizes Sizes Max Torque (Nm / Ft Lbf / In Lbf) Maximum Pressure @70F Maximum Pressure @250F 1.5" 12-14 / 8.85-10 / 106-124 2500 1500 2" 12-14 / 8.85-10 / 106-124 2500 1200 3" 12-14 / 8.85-10 / 106-124 2500 1200 4" 12-14 / 8.85-10 / 106-124 1800 1000 6" 12-14 / 8.85-10 / 106-124 800 400 8" 12-14 / 8.85-10 / 106-124 500 250 10" 12-14 / 8.85-10 / 106-124 300 175 12" 12-14 / 8.85-10 / 106-124 250 125

$43.02 - $339.97

-

Pro Series Manifold

Pro Series Manifold with Charging Hose Set R290/R600 This manifold is designed for R290 and R600 Propane and Butane solvents for closed loop extraction systems and for nitrogen assistance to push solvent through the system. When used in an active closed loop recovery and circulation system, the manifold allows the user to control the solvent input via the manifold through the gauges and allows you to monitor the pressure and vacuum of the system while it is running. Specifications: Aluminum Block Body 1/4" SAE Brass Fittings 60mm Gauges Refrigerants: R1270/R290/R600a BAR, PSI, Celsius Temp. Ratings: 100C Pressure Ratings: 800PSI High Side, 500PSI Low Side Includes 3 Multi-Colored Charging Hoses.

$62.44 - $69.38

-

Pro Series Oil Mist Filter Replacement Cartridge

BVV™ Pro Series Oil Mist Filter Replacement Cartridge This is a replacement oil filter cartridge for the BVV™ Pro Series line of vacuum pumps. It is easily swapped out by taking off the oil mist canister from the pump and removing the clamp. The cartridges are sizes for our 5.6CFM, 11.3, and 21.2CFM pro series vacuum pumps. They prevent oil mist vapors from escaping the vacuum pump creating a cleaner air environment during operation.

$166.52 - $222.02

-

Pro Series Vacuum Pump Oil Mist Filter KF25

Pro Series Vacuum Pump Oil Mist Filter Pro Series Vacuum Pump Oil Mist Filter allows the user to filter out any oil mist due to the vacuum process and will eliminate your work area from being contaminated with fine oil mist. An oil mist filter also captures the oil and lets it drain back into the vacuum pump after the pump is turned off and making the vacuum pump noticeably quieter during operation. The Oil Mist Filter also has KF25 High Vacuum end connections. There are 2 sizes of the oil mist filter for our Pro Series Vacuum Pumps, one fits the 5.6CFM and the other is interchangeable between the 11.3 and 21.2CFM sizes. A KF25 gasket and Clamp is included with every Pro series pump and can be purchased separately if needed. These oil mist filters can be used with any vacuum pump with KF25 connections. We recommend the 5.6CFM for any vacuum pump up to 10CFM. We recommend the 11.3-21.2CFM for any vacuum pump up to 24CFM.

$305.28 - $374.66

-

Propylene Glycol Tech Grade 100%

Propylene Glycol Disclaimer: Spigots/Faucets are only compatible with 5 Gallon Jugs and must be purchased separately BVV™ brand propylene glycol is a great heat transfer fluid alternative to water for all processing equipment such as refrigerated or heated circulators and cold traps. This propylene glycol has a freezing point of -74°F and a boiling point of 370°F. BVV™ propylene glycol is considered NOT genetically modified and NOT derived from a genetically modified organism. BVV™ Propylene Glycol SDS BVV™ Propylene Glycol Certificat of Analysis COA The expiration date is 2 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$23.59 - $4,301.64

-

Propylene Glycol USP 100%

Propylene Glycol USP 100% Disclaimer: Spigots/Faucets are only compatible with 5 Gallon Jugs and must be purchased separately BVV™ brand propylene glycol is a great heat transfer fluid alternative to water for all processing equipment such as refrigerated or heated circulators and cold traps. This propylene glycol has a freezing point of -74°F and a boiling point of 370°F. BVV™ propylene glycol is considered NOT genetically modified and NOT derived from a genetically modified organism. BVV™ Propylene Glycol SDS BVV™ Propylene Glycol Specification Sheet The expiration date is 2 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$30.53 - $4,509.79

-

QTests Psilocybin QTests