All products

5LB TFX Closed Loop Extractor

5LB TFX Closed Loop Extractor Are you ready to embark on an exciting journey into the world of extraction? Look no further than the TFX – your ultimate entryway into the realm of closed-loop extraction. The TFX not only offers exceptional performance straight out of the box at an affordable price but also serves as a dynamic foundation for future upgrades and enhancements, allowing you to elevate your extraction prowess over time. Whether you're just starting your extraction venture or seeking to amplify your capabilities, the TFX provides a sturdy base that can be tailored to meet your evolving requirements. With its adaptable design and compatibility with various upgrades, the TFX empowers you to experiment with novel processing techniques and adapt to the ever-changing demands of the industry. Initiate your journey with the TFX and unlock boundless possibilities for innovation and expansion in the extraction domain. Introducing the TFX closed-loop extractor – the evolution of the popular Apollo extractor. The TFX heralds a new era of safety, user-friendliness, and performance. Building upon the achievements of its predecessor, the TFX takes operator safety to new heights, featuring enhanced safety mechanisms such as High-pressure Clamps and pressure relief valves as standard features. Harvesting extracts is made effortless with splatter platter bases, ensuring a cleaner and more seamless process. The optimized design of the TFX translates to heightened ease of use, safety, and performance, resulting in top-tier extracts. The TFX stands as the cornerstone of many extractors' journeys, providing a reliable, efficient, and future-proof solution to meet your evolving demands. The TFX closed-loop extractor comes in three model variants, tailored to different extraction needs. The V1 Explorer is the ideal choice for those mindful of their budget, offering an affordable entry point into the extraction world. Equipped with features like a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, it establishes the groundwork for seamless future upgrades. For those seeking a professional setup from the outset, the V2 Professional model is the prime selection. It boasts an upgraded stainless steel recovery tank with 1/2" JIC Recovery lines for optimal solvent recovery. Enhanced borosilicate sight glasses provide improved visibility during the extraction process. For the ultimate extraction experience, the V3 Elite model is your answer. It encompasses all the upgrades of the professional variant, along with additional features such as a solvent dispersal plate for uniform biomass saturation and a jacketed splatter platter compatible with a heated circulator, enhancing solvent recovery efficiency. The TFX closed-loop extractor empowers you to choose the model that suits your budget and needs perfectly. Whether you're taking your first steps or aiming for professional-grade capabilities, the TFX series lays the groundwork for your extraction journey. Regardless of your choice – Explorer, Professional, or Elite – the TFX closed-loop extractor offers endless modification possibilities to amplify your capabilities and remain ahead of industry trends. Tailored for quick wash extraction procedures, the TFX guarantees outstanding purity and yield. For those inclined towards soaking procedures, a simple addition of our 316L SS Tri-Clamp Ball Valve beneath the material column transforms the TFX. For utmost purity, pair your TFX with an Inline CRC (Color Remediation Column) to achieve the highest quality and purest extracts. Planning to work with fresh frozen material? Swap out the standard 4"x 24" spools for Sleeved Spools to preserve the biomass's flavor during extraction. To attain unparalleled clarity in your extracts, reduce wax content by integrating an injection coil into your setup. To enhance solvent recovery efficiency and minimize loss, consider adding our BVV 2 Cylinder Active Closed Loop Recovery kit to your TFX closed-loop extractor. This kit optimizes solvent recovery, ultimately saving you valuable time and resources. With the TFX closed-loop extractor and its range of modification options, you have the freedom to tailor your extraction setup to match your distinct requirements. Stay at the forefront of the industry and unlock the full potential of your extraction process with the versatile TFX closed-loop extractor. As a prominent manufacturer of extraction equipment, we prioritize precision and safety in the extraction process. The TFX embodies these principles, offering a state-of-the-art solution for extraction professionals. Engineered from high-quality stainless steel, the TFX guarantees exceptional durability and corrosion resistance, providing you with a dependable and enduring extraction solution. Its innovative design integrates advanced safety features such as high-pressure clamps, pressure relief valves, and sight glasses, ensuring operator well-being and operational control. Its superior design promotes efficient solvent flow and comprehensive material saturation, resulting in high-quality, potent extracts that meet your specific requirements. When it comes to introductory closed-loop extractors, the TFX sets a new benchmark with its exceptional performance, safety features, and reliability. With our product, you can streamline your extraction operations, amplify productivity, and craft premium extracts that surpass industry standards. At BVV, we take pride in offering top-tier extraction equipment tailored to your unique needs. Our team of experts is devoted to providing unparalleled customer support, assisting you every step of the way, from your initial purchase to setup and beyond. Elevate your butane extraction experience with the TFX – the definitive top-fill closed-loop extractor. Reach out to us today to initiate your extraction journey and propel your business to new heights. Specifications 2X 4"x24" 1LB Material Column 12"x12" Collection Base Body 12" Collection Base Splatter Platter 100um Nitrile BUNA-N Mesh Gaskets 1.5" Polycarbonate or Borosilicate Sight Glasses 125 PSI ASME Safety Valves -30hg-250PSI Compound Pressure Gauge 1/4" or 1/2" Full Bore Recovery Lines 1/4" JIC process Flow lines Explorer Professional Elite DOT Carbon Steel Solvent Tank Polycarbonate Sight Glasses 1/4" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Solvent Dispersal Plate Jacketed Splatter Platter ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$1,991.35 - $3,058.14

6" Sauce Separator

6" Sauce Separator Separate diamonds from sauce at scale with our 6" Sauce separator. Simply load your crystallized extract into the top vessel and place it in a heated oven at 120-140F for 4 hours to sweat the sauce from your crystals. Equipped with a 100-micron Buna-N gasket the 6" Sauce Separator allows for easy separation of crystals from the mother liquor. With a max height of 12.5" and a max diameter of 9", the 6" Sauce Separator easily fits within our standard 1.9 CF vacuum ovens. Specifications 6" Splatter Platter for sauce collection 6" 100 Micron BUNA-N Nitrile gasket 6"X6" Body for Extract loading (-30)-250 PSI Compound Gauge 1/4" JIC Butterfly Valve 1.5" Borosilicate Sight Glasses High-Pressure Clamps Dimensions Max Height: 12.5" Max Diameter: 9"

$640.08

12" Collection Base

Pre-Built 12" Collection Base Double your capacity or configure your own custom system with BVV's Pre-Built 12" Collection base. Available in three different variations to suit your application all models of BVV's Pre-Built 12" Collections Base comes standard with high-pressure clamps, borosilicate sight glasses, and full-bore ball valves. Version 1 is the base model equipped with the standard 12" welded base perfect for cost-conscious applications. Version 2 is equipped with a 12"x12" spool & 12" splatter platter to make extract harvesting a breeze, and Version 3 is the top of the line 12" Colleciton base equipped with a 12" jacketed splatter platter for both optimized solvent recovery and ease of harvesting extract. Specifications High Pressure Clamps 2X 2" Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauge 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves Maximum Pressure Rating: 125PSI Variations V1 : 12x12 Base (1200X12B) V2: 12" Splatter Platter base (1200X12S+1200SPL) V3: 12" Jacketed Splatter Platter Base (1200X12S+1200FJS)

$1,304.33 - $1,836.31

Nitrogen Pressure Filter

Nitrogen Pressure Filter Is vacuum filtration bottlenecking your processing? Filter faster with BVV's Nitrogen assisted pressure filters. Designed for versatility our prebuilt pressure filters come complete with our 1 micron Dutch Weave Sintered disk for ultra-fine filtration. Process continuous or batch-style solutions in half the time compared to most vacuum filtration applications. Specifications 6"x12" or 12"x12" filtration body 1um Dutch Weave Sintered disc Filter Plate Retention Ring Fast Flow Filter paper Included Solvent dispersal plate 2X Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves 1X JIC Drain Valve (6NPS: 1/4" 12NPS: 1/2" JIC) Maximum Pressure Rating: 125PSI

$1,991.35 - $3,769.33

1.5" Tri-clamp Thermometer

1.5" Tri-clamp Thermometer High-quality adjustable stainless dial 1.5" Tri-clamp thermometer with back mount orientation. This thermometer is perfect for process temperature monitoring in sanitary applications allowing precise monitoring of temperature. The stainless Dial Thermometer face is 3-inch diameter and reads 0 to 220 degrees in Fahrenheit and 0 to 100 degrees in Celsius. This thermometer is 1.5″ Tri-clamp and the probe depth from the tri-clamp is 2″ long.

$71.12

Heavy Duty Steel Mobile Cart for Vacuum Ovens

Heavy Duty Steel Mobile Cart for Vacuum Ovens Our heavy-duty cart is designed and built to house a variety of equipment such as vacuum ovens, cold traps, vacuum pumps, etc. The cart can comfortably house up to 3 BVV™ and Across International 0.9 and 1.9 vacuum ovens. The cart offers mobility with their swivel caster wheels and can withstand up to a total of 1,100lbs. Included in the unit are three side shelves in which the height can be adjusted to your needs. The cart was meticulously designed for reliability, customization, and convenience for your process. Features: White powder coated carbon steel. 3-shelf shelving unit 3 laser cut, height adjustable side shelves. 2⅜” diameter hole to help with hose and cable management. 6” front lip for easy oil drainage. Can fit on the left or right side of the bracket Four 3” swivel caster wheels: 2 with brakes and 2 without brakes. Dimensions: 33” (L) x 23” (W) x 61” (H). Additional 13¼” to the length with side shelves added. Made in the USA. Note: The unit shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$2,119.36

BVV Compression 6" Tri-Clamp x (3) 1.5" TriClamp x (2) 3/8" Compression x 1/4" Compression x 1/2" Compression Hemispherical Lid

BVV Compression 6" Tri-Clamp x (3) 1.5" TriClamp x (2) 3/8" Compression x 1/4" Compression x 1/2" Compression Hemispherical Lid This End Cap comes with (4) Compression connections and Three 1.5" Tri-Clamp ferrules welded to the end cap with a sanitary weld with a 3" Tube Extension Below the Lid. They allow the user to adapt and connect a tube stub connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 7 connections are welded on a 6" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 1.5" Tri-Clamp with 3" Tube Extension Below Lid on Center Tri-Clamp Port 6" Tri-Clamp 1/4" and 1/2" Female Compression Connections Standard: 3A

$277.37

Viton Replacement O-ring for TRS21 and BVV 2/4CYL Suction Valves

Viton Replacement O-rings for TRS21 and BVV 2/4CYL Suction Valves sold as single O-ring.

$2.84

CHEMTEK D-Wax

CHEMTEK D-Wax D-Wax is a silica with high adsorption capacity and strong affinity for phospholipids, trace metals, and soaps. It contains 50% water and citric acid to remove both hydratable and non hydratable phosphatides. D-Wax SDS

$113.79 - $654.30

Certified 280L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 85LB Max Capacity

Certified 280L Ethanol Wash/Dry Centrifuge NOTE: This item currently has a 2 week lead time. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it and will also ship via freight only. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1000 RPM with Gradual Speed Stepping 559 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 280L Drum Dimensions 39.4" (1000mm) Diameter x 14.17" (360mm) Speed 0-1000r/min Weight 4,188lbs (1900KG) Exterior Dimensions 59.06" x 82.68" x 45.28" (1500x2100x1150mm) Material 304 Stainless Steel Motor Power 11KW Explosions Proof - 220v 60Hz 3 Phase

$51,206.06 - $56,895.62

Replacement Gasket for Borosilicate Tri-Clamp Sight Glasses - Silicone

Replacement Gasket for Borosilicate Tri-Clamp / Tri Clover Sight Glasses This is a Silicone Gasket Replacement for Borosilicate Tri-Clamp / Tri Clover Sight Glasses

$8.53 - $9.96

10L Premium Short Path Distillation Turnkey System

10L Premium Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Premium Short Path Distillation Turnkey System features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Polyscience 15 Liter Advanced Digital Heated Circulator BVV™ 21.2CFM Pro Series Corrosion Resistant Vacuum Pump Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$16,357.49

So-Low -85°C Ultra-Low Chest Freezer - 5 Cubic Ft.

So-Low -85°C Ultra-Low Chest Freezer - 5 Cubic Ft. Please note: This Product may carry up to an 8 week lead time! So-Low Ultra-Low Chest Freezers are second to none in low temp applications to suit any laboratory or application needs. These Ultra-Low Temp freezers feature digital temperature control with 2 temperature displays. One shows the set temperature and the other shows the actual temperature in the freezer. The So-Low C85-5 features a battery operated alarm system that will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Product Specifications Temperature Control Digital Control with two temperature displays. One display shows the set temperature, the other shows the actual temperature in the freezer. Alarm System Battery operated alarm system will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Remote Alarm Relay A relay for a remote alarm hook-up is also provided. Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish. Voltages Available 115/60/1 - 208/60/1 - 230/60/1 - 220/50/1 Technical Support Supplied by Nation-Wide-Network of service companies. ETL Electrical Approval Specification Data Sheet Diagram Data Sheet Specification Manufacturer So-Low Temperature Range -40°C to -85°C / -40°F to -121°F Capacity 5 Cubic Ft. / 142 Liters Dimensions: Exterior: 40.5" x 31" x 47" Interior: 30" x 18" x 16" Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish.

$9,672.26 - $10,383.45

Female Elbow

SSP - Female Elbow SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. BVV recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$14.22 - $19.91

Pump Rebuild Kits for 14.1 - 21.2 - 35.3 Pro Series Pumps

Pro Series Vacuum Pump Complete Service Kit This is a complete vacuum pump service kit for the BVV™ Pro Series 14.1, 21.2, 35.3CFM line of vacuum pumps and allows the user to completely rebuild their pump and keep it running like new.

$604.52 - $782.31

Insulation Jackets for Centrifuges

Insulation Jackets for Centrifuges ***Disclaimer: Fiberglass may be present on the exterior of the jacket and users should use PPE when handling the jacket. These insulated jackets are specifically designed to fit BVV brand Centrifuges and allow the user to better control and keep a more stable temperature when running the system. The jackets are made out of flame retarded material and are insulated with fiberglass.

$640.08 - $1,635.75

8CF CSA Certified Lab Grade Forced Air Convection Drying Oven – 16 Shelves Standard

8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 16 Shelves Standard DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! The 8CF CSA Certified Laboratory Grade Drying Oven is our newest addition to the Best Value Vacs line of Laboratory-grade processing equipment. Offering a leading ±1⁰F temperature stability, over 98% heat uniformity, and no overshoot, technicians can now process material with ease and confidence. We regulate heat using a modern, high-precision PID controller with a large, bright display and touchscreen buttons. The interior is a high-polish stainless steel, presenting a clean and easy to maintain surface. Our drying oven comes fully-stocked as a standard- offering ten spacious, wire frame shelves you can easily insert, remove, and clean. With a clear, no-overshoot advantage, there’s simply no better choice for your precision processing needs. Key Oven Features: Long-lifetime convection fan gently circulates air for optimal heat distribution Stainless steel interior for a sanitary, easy-to-clean look 16 spacious, wire racks are easy to insert and remove Level-adjusting caster wheels for mobility and stability Overload circuit breaker for electrical protection Large, tough, stainless steel door handle feels solid and works great Temperature overshoot protection enabled Digital timer allows users precise control of heating cycle Simple and powerful user interface presented in a large, bright, clear display Specifications Electrical 220 VAC / 60Hz / 2450W / USA Plug Internal Chamber Material: Polished Stainless Steel Dimensions (LxWxH): 23.62" x 19.69" x 29.53" External Dimensions 35" x 25" x 37" Temperature Control LED PID Controller Temperature Range: RT+18F - 572F Temperature Stability: +/- 1F Temp Resolution: +/-0.1F Heat Uniformity: 98% Shelves Up to 16 Removeable Shelves Door Dual Layer Observation Window made from Tempered Glass Replaceable Gasket Material: Silicone Compliance CSA Certified *ISO 9001:2005 Note: This item is a freight ship item and will ship Via Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise freight Cannot Contact you for a delivery setup window.

$4,551.65

304 Stainless Steel Carboy

304 Stainless Steel Carboy This 304 stainless steel carboy is a very durable upgrade from plastic carboy's and allows it to be cleaned and sterilized much better. This unit comes with (2) 1/4" FNPT ports and (1) 6" Tri-Clamp top port and heavy-duty welded handles. For Storage and Vacuum Use Only Max Pressure 10 Psi ONLY (Note: This unit comes bare and does not include any fittings.)

$853.43 - $1,280.15

250ml Bump Trap 24/40 Male to 24/40 Female

Bump traps are used on rotary evaporators between the evaporating flask and condensing column. They help prevent contamination in the collection vessel when “bumping” occurs. When “bumping” occurs substance in the evaporating flask shoots up and ends up in the collection flask, which is unwanted when operating. This bump trap features a 250ML round flask with upper 24/40 female ground joint and bottom 24/40 male ground joint. With the use of ground joints vacuum grease must be applied to assure a tight seal. Internally, there is a tube that extends and two openings on the sides. This is what stops the bumping from occurring. If any substance makes its way through the openings, it will get trapped in the flask. Vapor is still allowed to flow freely through the openings. Recommend using this bump trap on 2L rotary evaporators and other distillation setups it has an overall length of 9". Specifications Material Borosilicate Flask Size 250ml Top Connection 24/40 Female Ground Joint Bottom Connection 24/40 Male Ground Joint *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: Best Value Vacs is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$85.34

KF Sight Glass

These 4 piece sight glasses can hold high vacuum levels on a system with KF connections. The housing is made of 304 stainless steel with a viton x-profile seal. The glass is tempered, impact resistant glass that increases the longevity of the sight glass. The connection sizes available are: KF25 (NW25) KF40 (NW40) KF50 (NW50) *Light assembly may be required with a 5/64" Allen wrench. Before assembly, a light application of vacuum grease on the gasket is recommended.

$105.26 - $159.31

CO2 Tank Filled, 600g E290 Food Grade

CO2 Tank 600g Food Grade E290 - Liquid CO2 Filled Made in Italy Our CO2 tank arrives filled with 600g of compressed liquid CO2. The gas can be removed using our regulator or valve dispenser that attaches to the top of the tank. Tank Thread: M11 x 1.0 Regulator Thread: M11 x 1.0 (Connects to tank) Regulator Output: 1/4" Brass Barb Valve Dispenser Output: 1/4" Brass Barb Valve Dispenser Thread: M11 x 1.0 (Connects to tank) *Tank is non-refillable *At end of use, completely empty the tank for recycling. *Note CO2 Tank Pressure is 855PSI Tank Volume of Helium Product Sku: 600g / 326.8 Liters / 86.3 Gallons CO2-600G Regulator/Dispenser Details (not included with tank only purchase) Regulator - Adjustable via. needle valve, regulated to 80 PSI. Made in Italy. Thread: M11x1 (tank connection). Output: 1/4" Barb to connect to any hose with a 1/4" I.D. (inside diameter) Gauges read in BAR. M11 Valve Dispenser Kit - Includes adjustable pushpin style valve dispenser. Output: 1/4" Brass Barb, NO GAUGES Chemical Formula: CO2 Molecular Weight: 44.009 g/mol CAS Registry Number: 124-38-9 Appearance Colorless Odor: Odorless Density 0.114 lb/ft3 (178.6 g/m3) Boiling Point: N/A Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H280, H281 GHS Precautionary Statements P282, P336+P317, P403, and P410+P403 UN Identification Number: 1013 Proper Shipping Name: Carbon Dioxide Transport Hazard Class: 2.2 Packing Group: None DOT Placard: Carbon Dioxide Safety Data Sheet (SDS)

$36.98 - $149.35

Media Bros Medium flow CRX-M

Media Bros Medium flow CRX This non-reactive medium flow variant allows operators to increase operating pressures and surface area for a more fine-tuned process. PH 7 Description: Introducing CRX Medium Flow™ (CRX-M™), a not-quite-powder/fine-grain premium filter media formulated for non-reactive, high flow and high-pressure hydrocarbon extraction. Its texture is designed to replace traditional powdered media like B80 without channeling and clogging issues commonly encountered with conventional powders. Extractors accustomed to traditional powders like B80 will find that CRX-M™ offers similar flow properties but with the added benefit of superior terpene retention. Like all of our premium blends, CRX-M™ is non-reactive, ensuring it's safe and easy to handle in your lab setting. It eliminates the need for extensive clean-up, saving you time and effort. CRX-M™ has all the benefits of its more granular twin, the flagship CRX™. It is a "perfect scrub" media, ideal for high-quality biomass and nug run processing. You want total control over flow and ensure the terpenes and flavonoids are retained from plant to extracted oil. Extraction labs vary in size, and so does our range of filter media. Our CRX-M™ product is available in three convenient packaging options: a 1.5 kg pouch, a 10 kg bucket, and a 100 kg drum. Whether operating on a small scale or running an extensive industrial process, we have the perfect packaging to meet your needs. Technical Specs: Solvent Type Hydrocarbon Color Remediation Level Average/Moderate Pesticide Remediation Level Low Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation No Moisture Remediation Level Low Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Moderate Flow pH Level Neutral (pH 7) Best For Fresh Frozen, Nugs, High Quality Suitable for Reruns No Distillation Clean-up Low Scrub SOP SDS Before you get started, please remember this: As CRX™ and CRY™ are not powders designed not to absorb moisture before use, no baking or preparation is needed. For optimal success, ensure your flow is gentle and consistent. RATIOS Solvent to Biomass: ratios range from 6:1 to 10:1, depending on the quality of the plant matter you are distilling—lower ratios for top-tier biomass and higher ratios for older or lower-quality biomass. Media to Biomass: Load 150 - 250 grams of filter media into filtration housing for every 1 lb of biomass. The media quantity used is dependent on the quality of the biomass. Higher-quality biomass requires less media. Lower-quality biomass requires more media. The lookup table can be used as a reference, but because every kind of plant matter is different, you will need to experiment a little bit to achieve the best results. That said, this chart is an excellent baseline from which to start. TEMPS To ensure optimal performance, keep the temperature at -10°C or below while using the media. Our media is designed to prevent clogging. FLOW When transferring from the biomass vessel to the recovery vessel, maintain a maximum flow rate of 1 GPM. Our media performs best with a consistent and gentle flow. To prevent channeling, avoid sudden hydraulic surges through the CRC column. A shower or initial fill of the column is highly recommended for optimal results. YIELD Any lost yield can be fully recovered by flushing the media with solvent. Most users report achieving substantial yield gains by maintaining high solvent-to-biomass ratios or flushing our media after an extraction transfer.

$42.67 - $2,275.82

Centrifuge C250

BVV C250 Centrifuge The BVV C250 Centrifuge is a large-capacity desktop centrifuge with broad functionality suitable for various applications. The BVV C250 Centrifuge can be used to separate or concentrate samples by density or utilized to separate solid constituents from liquid constituents. The BVV C250 Centrifuge has a maximum speed of 5000rpm with a maximum centrifugal force is 3899xg which allows for fast separation times. It's user friendly simple to use touch screen interface allows for easy operation even when wearing gloves. With built-in cooling fans, the BVV C250 ensures sample preservation while allowing for heat-assisted separations. While the BVV C250 is not actively heated or refrigerated it typically operates at 130F/54C allowing for quick and efficient separations. For Solid & liquid separations we recommend utilizing our 45 Micron Large Rosin Bags, The BVV C250 comes with 3 sets of centrifuge baskets including: 4X 250ML Stainless Steel Separators 4X 2X 50ML Centrifuge Tube Plastic Inserts (8X 50ML Centrifuge Tube Capacity) *Centrifuge tubes not included* 10X Small Rosin Bags 45 Micron Features •Digital LCD display with a user-friendly interface for easy operation. •Microprocessor control, DC brushless motor with low noise and high accuracy. •Dual locking design with lock alarm on the interface. •Centrifuge chamber is made of 304 stainless steel to avoid corrosion. •Can switch RPM/RCF during operation. •Store up to 10 preset programs •Sound and indicator alarm for defaults. •Protection including door closing, malfunction, over-speed, over-heating, imbalance,etc. •Speed is adjustable to avoid sample suspension to ensure the performance. Technical Specifications Model BVVC250 Max Capacity 4*250mL Max Speed 5000rpm Max RCF 3899Xg Speed Accuracy ±10r/min Time Setting 0-99min59s Soft Brake 9 Ramps Noise ≤65dB(A) Power Supply 110V 60HZ Power Consumption 500W Net Weight 66lb/30kg Packing Size 20"x14"x*11"

$4,196.05

2540 Membrane Housing Kit

2540 Membrane Housing Kit This is a membrane housing kit designed to fit Snyder 2540 membranes. The inner diameter of the housing measured 2.519' (64MM) and measured 46" from end to end. The opposing 1.5" tri-clamp ports protrude 3.5" from the center of the housing and are spaced 42.5" apart measured from the center of each ferrule. This housing kit includes 3" tri-clamp end caps that accept the membrane permeate adapters to perfectly support the membrane within the housing. The permeate adapters include 014 Viton O-rings to perfectly seal the permeate stream from the retentate stream. To complete the housing this kit Includes 2X 3" High pressure Clamps and 2X 3" Silicone gaskets. Components: 1X 2540 Membrane housing (2X 3" TC ports, 2X 1.5" TC ports 1X 3" Permeate endcap with 3/8" NPT outlet 1X 3" Solid end cap 1X Solid Membrane Insert 1X Membrane Permeate Insert 2X 3" High pressure Clamps 2X 3" Silicone Tri-clamp Gaskets 6X 014 Viton O-Rings

$2,133.59

36 inch Filtration Funnel V2

Buchner Filtration Kit This filtration kit is operated by using a vacuum pump to pull the solution through the filter paper to remove particulate. The funnel has a 36" perforated plate to support the filter paper.

$10,810.17 - $11,635.15

BVV Pro Series Oil Mist Filter/Trap

BVV Pro Series Oil Mist Filter/Trap Pro Series Vacuum Pump Oil Mist Filter allows the user to filter out any oil mist due to the vacuum process and will eliminate your work area from being contaminated with fine oil mist. An oil mist filter also captures the oil and lets it drain back into the vacuum pump after the pump is turned off and making the vacuum pump noticeably quieter during operation. The Oil Mist Filter also has KF25 flange for the 14.1 and 21.2CFM or KF40 flange for the 35.3CFM. A gasket is included with every Pro series pump but standard gaskets and clamps can be purchased separately if needed. These oil mist filters can be used with any vacuum pump with KF25 or KF40connections. We recommend the 14.1 and 21.2CFM for any vacuum pump up to 24CFM. We recommend the 35.3CFM for any vacuum pump up to 40CFM.

$355.60 - $540.51

Neo Vacuum Oven Valve Knob

Replacement Valve Knob for BVV Neocision Vacuum Ovens.

$21.34

Pressure-Relief Valves for Cryogenic Liquids

Pressure-Relief Valves for Cryogenic Liquids Valve Function Pressure Relief For Use With Liquid Carbon Dioxide, Liquid Nitrogen, Liquid Oxygen Activation Pressure Driven Inlet Pipe Size 1/4 Connection Type Pipe Pipe Connection Type Threaded Connection NPT Male Location Bottom Maximum Pressure 600 psi Relief Port Thread Size 3/4"-20 Connection Type Pipe Pipe Connection Type Threaded Connection UNEF Female Location Top Set Pressure Accuracy ±5% Set Pressure Configuration Nonadjustable Temperature Range -320° to 165° F Shape Straight Overall Height 2 5/8" Material Body Brass Valve Type Relief Flow Coefficient (Cv) Not Rated Specifications Met CGA G-4.1 RoHS RoHS 3 (2015/863/EU) compliant with exemption 6(c) - Lead in copper alloy REACH Not Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 848140.0000 ECCN EAR99 Cleaned and bagged to meet CGA G-4.1 for oxygen service and other high purity applications, these valves are built to withstand the extreme cold of liquid carbon dioxide, liquid nitrogen, and liquid oxygen. They begin opening at the set pressure and fully open at about 10% over the set pressure. Valves begin closing as pressure drops and fully close when the system pressure is restored below the set pressure. Set pressure is not adjustable. Valves are not intended for direct contact with cryogenic liquids. Risers (sold separately) are required to convert cryogenic liquids into gases before they contact the valve. 3/8 NPT valve requires a 1/2 NPT × 3/8 NPT bushing when using a riser.

$155.04

Refurbished BVV 12 CFM Two Stage SPARK FREE Vacuum Pump

BVV™ SF12D 12CFM Two Stage Spark Free Vacuum Pump ***NOTE: Refurbished products are 100% re-tested at our warehouse to be fully functional. The customer acknowledges that by buying a refurbished product the item may have imperfections or slight damage to the product such as: Major/Minor Scratches Major/Minor Dents Smells or Odors (Cleaned as much as possible at warehouse) This is the BVV™ SF12D 12CFM Two Stage Spark Free Vacuum Pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Spark Free Construction Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient. Models BVVSF6S BVVSF6D BVVSF12D Stage 1 2 2 Ultimate Vacuum (Microns) 75 15 15 Refrigerant Classes A1 Non-Toxic, Non Flammable A2 Non-Toxic, Low Flammability A3 Non-Toxic, High Flammability Dimensions (in) 12.4 x 4.8 x 10.16 13 x 5.5 x 10.7 15 x 6.3 x 11.22 Weight (lbs) 16.5 24.3 33.6 Free Air Displacement 6.4 CFM 6.4 CFM 12.8 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 14.5oz / 410ml 19oz / 410ml 20.6oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Ignition Proof On / Off Switch Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve No Yes Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information • Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™)• If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void.• These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. • When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.)• To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$704.08$426.72

Cascade 20L Bead Bath with 15L Lab Armor Beads

Cascade 20L Bead Bath Bye-Bye Water Bath! Traditional water baths are associated with messy condensation and the growing of harmful germicides. Cascade Sciences Bead Baths are the next generation of a decades-old lab bath technology. With the included thermal beads, this 20L Cascade Bead Bath operates in a constant, stable, broad temperature range between -80°C to +180°C. The bath itself delivers exceptional temperature uniformity up to 80°C. Zero Evaporation Saves Energy In a water bath, the water is constantly evaporating. As water evaporates, it cools. Because evaporation has a cooling effect, a water bath must heat more frequently. A bead bath uses 4X less energy when set to 65°C and 2X less energy at 37°C. The bead bath also provides more constant temperature with fewer temperature fluctuations during operation. Cascade Sciences Bead Baths and Thermal Beads and Made in the USA and NRTL Certified Cascade Sciences Bead Bath Features: High Thermal Efficiency Microbial/Biofilm Resistant Cross-Contamination Resistant Minimal Cleaning No Refilling No Rack or Accessory Needed Angled Incubation Possible Constant Volume – No Evaporation Non-Corrosive Compatible with non-water tight vessels Independent build-in over-temp, burn-out protection No Warm Up Mobile or Field Use Compatible Non-Combustible Thermal Beads Replace Water and Ice Lab Armor™ Thermal Beads are small, dry, metallic thermal beads designed to replace water in laboratory water baths and ice in ice buckets. Their high thermal conductivity technology is patented and improves energy efficiency of standard water baths by over 50%. Improve lab cleanliness when using thermal beads in place of fluid in water baths. Thermal Beads – Recyclable Lab Armor™ Thermal Beads are formed from solid recyclable metal. The raw material used in Lab Armor™ Beads can be reused in other products. Lab Armor™ Thermal Bead Features: Metal composition with smooth round surface Moisture and gas impermeable High thermal conductivity Working temperature range is -80°C to 180°C Non-toxic, non-vaporizing material Recyclable! Multiple uses – ice replacement Frequently Asked Questions Are Lab Armor™ beads autoclavable?They are not. The steam and pressure ruins the surface of the beads. We recommend a dry heat sterilization: 180°C for 2.5 hours. For a quick touch-up we recommend spritzing with 70% ethanol and stirring. If some debris falls into the beads we recommend placing them in a pail with water and a small about of Dawn, rinsing out multiple times, and then putting through the dry heat sterilization process. How long can I use Lab Armor™ Beads under normal conditions?Under normal conditions, Lab Armor™ Beads should last the life of the bath. If used incorrectly or if not maintained and cleaned properly, the surfaces of Lab Armor™ Beads can become damaged. We recommend that you avoid strong detergents, acids and bases. Bleach, for instance, may tarnish the surface of the Lab Armor™ Beads, reducing its fluidity and overall performance. Can Lab Armor™ Beads be used as an ice bath?There are a number of different ways to use thermal beads. Many customers place containers of beads in their refrigerators, incubators and ovens. When creating an ice bath, be sure to keep the beads dry. We recommend separating the beads from the ice packs, which accumulate condensation. Some kind of mesh wire or fabric helps with this as well. Also, any condensation that builds on the surface of the beads will be able to drip through the mesh. It’s important to keep the beads from soaking in water for extended periods of time. Besides attracting contamination, excessive water contact will tarnish the surface of the Beads and reduce the fluidity of the bath. Also, as an alternative to ice packs, dry ice can be used to make a colder bath (<0ºC).

$4,907.25

Centrifuge Lid Replacement Gasket

Centrifuge Lid Replacement Gasket These lid replacement gaskets are cut to fit, they will not be fully connected once installed. The main purpose is to prevent splashing while operating, the gasket will not hold pressure.

$568.96 - $1,280.15

Julabo Adapter 8891609 M16x1 f to NPT 1/2″ f

Julabo Adapter 8891609 M16x1 f to NPT 1/2″ f 2 Adapters M16x1 f. to NPT 1/2″ f.

$364.13

Solvent Pro Series 60/80 Clamp and Gasket Set

Solvent Pro Series 60/80 Clamp and Gasket Set This is a replacement Clamp and Gasket for 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 60mm(2.36") Inner Diameter and 80mm(3.15") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$49.78

Pump Part - MVP - 60 PSI, 150 PSI, Liquid, XL150 - Diaphragm Cover Bolts - 8 pack

Pump Part - MVP - 60 PSI, 150 PSI, Liquid, XL150 - Diaphragm Cover Bolts - 8 pack All sales final

$156.46

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3081-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3082-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr Specifications Application CRVpro8 Free Air Displacement @ 60 Hz, cfm (L/min) 5.6 (158) Free Air Displacement @ 50 Hz, m³/hr (L/min) 8 (133) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1000 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 49.6 (22.5) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$5,902.92

KF-25 Stainless Steel 90 Degree Manifold

KF-25 Stainless Steel 90 Degree Manifold This 90 degree stainless steel KF-25 manifold has 2 1/4" FNPT ports and measures 10" x 7".

$92.46$56.90

Julabo C5 Thermal Bath Fluid - 10 Liters

Julabo C5 Thermal Bath Fluid JULABO Thermal bath fluids are ideally suited for all of your temperature control applications and guarantee safe and reliable operation. Choosing the proper bath fluid is critical for best results in temperature control. Viscosity, oxidation characteristics and heat transfer of Thermal fluids are specifically matched with each JULABO temperature control unit. C5 Thermal Bath Fluid SDS C5 Thermal Bath Fluid Product Data Sheet JULABO Thermal bath fluids have been carefully selected and are optimized for maximum performance with JULABO instruments. Benefits Low toxicity Low viscosity High stability Minimum odor Good heat conductivity Low corrosion tendency Wide temperature ranges Technical Data Order no. 10 liters 8891402 Working temperature (°C) -60...+110 Flash point (°C) > +135 Fire point (°C) > +443 Viscosity (kinematic at 20 °C in mm²/s) 5 Density (at 20 °C in g/cm³) 0.918 Pour point (°C) -100 Boiling point (°C) >205 Ignition temperature (°C) 443 Color clear

$3,006.93

HTP Big Daddy Press - 2 Ton

HTP Big Daddy Press - 2 Ton If you are looking for a quality press then the Big Daddy Press is for you! These high quality presses are built from Aircraft Aluminum and stainless steel designed to be used in conjunction with a unique heating process.The Big Daddy Press operates with a 2-Ton Hydraulic cylinder. It has a capacity of 3x3.High Tech Pipes make quality presses that are manufactured in the U.S.A. using American materials and labor. Each Press is assembled and individually inspected before shipping. Our Presses are designed to be heated to the ideal temperature which is an important aspect of the Pressing process. We design and build our products to stand the test of time and to become a permanent piece of equipment for the end user. We use aircraft aluminum which maintains heat as opposed to other Presses on the market which use steel that either quickly loses heat or heats up too fast thus destroying the material that is being pressed. Each Press comes with full step by step instructions and a video is available as well.

$597.33$561.84

2L Electric Lift Glass Axis

Glass axis for 2L Best Value Electric Lift Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$64.01

1/4" Cap

SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 0.92 in C 0.70 in D 0.60 in G 9/16 in H 1/2 in T 1/4 in B 0.63 in

$7.11$2.84

Table Clamp for Supporting Lattice

Table Clamp for Supporting Lattice This Table Clamp for supporting lattice can easily hold up to 12mm diameter rods.

$9.96

10L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

10L NEO Rotary Evaporator Turnkey System 10L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram 10L NEO Rotary Evaporator Turnkey System setup includes: 10L Neocision ETL Lab Certified Rotary Evaporator Polyscience 6160T 1HP Chiller 3/8" Gum Rubber - 100ft 3/8" Silicone Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. **Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$24,109.52 - $27,025.42

HUBER CS Chillers

HUBER CS Chillers The new CS chillers expand the Huber product range with compact and highly affordable recirculating coolers. The Huber CS chillers combine cool and smart technology in one unit. The new chillers further reduce water consumption and lower the operating costs for many applications. The investment pays itself off after a short time because of the water savings and the low purchase price. Your advantages: Working temperature from -20 °C to +15 °C Cooling power up to 70 kW Pump performance up to 125 l/min Quiet operation less than 79 db Economic and ecological solution to eliminate costly water waste Easy to use and maintenance free With a cooling power up to 70 kW, the devices are particularly suited for constant temperature control for laboratory applications, e.g. for cooling vacuum pumps, rotary evaporators, electron microscopy, AAS-devices, ICP-devices, extraction, distillation and many more. Sku Model Temperature Range Pump Vapacity Max/Pump Connection Cooling power(kW) at (°C) HeatingPower NoiseLevel Dimensions Voltage Data Sheet (°C) (l/min) (bar) 15 10 0 -10 -20 (kW) (dB) W x D x H (inch) PDF VDH1100664 CS 25 -20...15 50 4.5 1/2" 3.5 2.5 1.6 0.98 0.7 - 60 22.8 x 26.0 x 32.3 208V 2~ 60Hz VDH1101336 CS 35 -20...15 30 4.0 1/2" 4.0 3.5 2.1 2.0 0.8 62 22.8 x 26.0 x 32.3 208V 2~ 60Hz VDH1100689 CS 50 -20...15 83 4.0 3/4" 8 5 4.2 3.5 2 - 63 26.8 x 28.7 x 59.8 460V 3~ 60Hz VDH4100126 CS 50-H -20...85 83 3.7 3/4" 8 5 4.2 3.5 2 2.8 63 26.8 x 28.7 x 59.8 460V 3~ 60Hz VDH1100690 CS 100 -20...15 83 4.0 3/4" 18 10 9.5 7.5 4.5 - 70 31.5 x 33.5 x 65.6 460V 3~ 60Hz VDH4100106 CS 100-H -20...85 83 3.7 3/4" 18 10 9.5 7.5 4.5 5.5 70 31.5 x 33.5 x 65.6 460V 3~ 60Hz VDH1100688 CS 200 -20...15 125 4.2 1" 28 20 18 15 9.5 - 78 55.1 x 39.4 x 70.9 460V 3~ 60Hz VDH4100091 CS 200-H -20...85 125 4.2 1" 28 20 18 15 9.5 5.5 78 55.1 x 39.4 x 70.9 460V 3~ 60Hz

$22,047.05 - $81,431.86

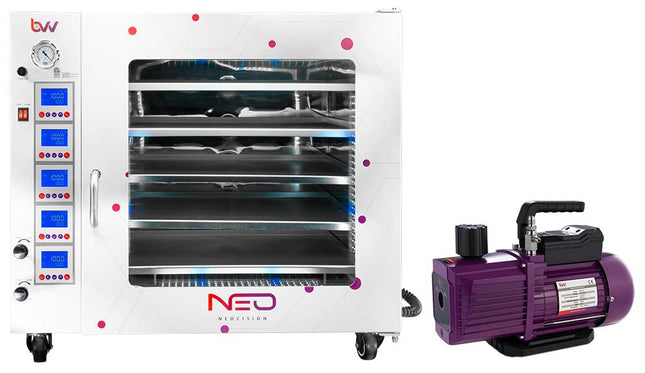

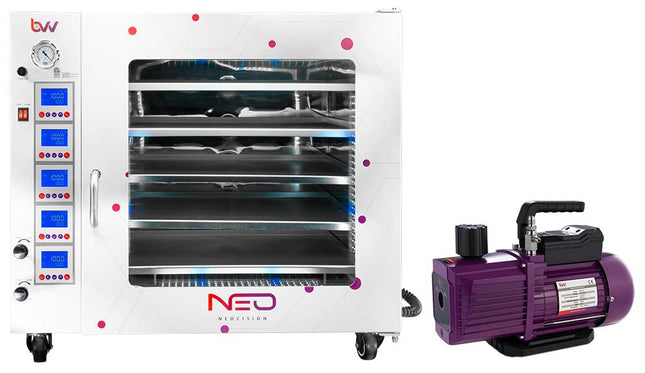

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and and V9D 9CFM Two Stage Vacuum Pump kit

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and V9D 9CFM Two Stage Vacuum Pump Kit Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 10 minutes to 29"Hg Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Individual Direct-Heat shelves Temperature Range RT+18°-212°F Chamber Material Stainless Stee Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump Best Value Vacs VE280 9CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$11,948.08

$14.22

Liquid Filled Vacuum Gauges - NPT Lower Mount

Liquid Filled Vacuum Gauges - NPT Lower Mount 2-1/2" Liquid Filled Pressure Gauges - Stainless Steel Case, Brass, 1/4" NPT, Lower Mount Connection Dial Size: 1-1/2", 2", 2-1/2" or 4" Dial Sizes (Crimped Casing) Accuracy: +/- 3/2/3% Scale: Dual Scale - PSI/Bar Movement: Copper Alloy* Bourdon Tube: Copper Alloy* Window: Poly-carbonate Case: Stainless Steel case for protection in harsh environments Connection: Copper Alloy Lower Mount*: 1/8" NPT for 1-1/2" dial, 1/4" NPT for 4" dialsNormal Ambient Temp: -4F to +140F (-20C to 60C) 2-1/2" Oil Filled Vacuum Pressure Gauge - Stainless Steel Case, Brass, 1/4" NPT, Lower Mount Connection, -30HG/30PSI

$17.07

Compression Ball Valve

BVV manually operated two-way ball valves provide quick ¼ turn directional flow control of fluids in instrumentation and process systems. Features: Directional handle indicates flow direction Panel Mountable 90-degree actuation Straight through flow path Micro-finished ball provides positive seal Free-floating ball design provides compensation for seat wear for repetitive sealing Blow-out proof ball & stem BVV™ Compression Ball Valve - Data Sheet Specifications Body Material 316L Stainless Steel Pressure Rating @ 100F 1000 PSIG Connection Type 1 Double Ferrule Tube Fitting Connection Size 1 Specified by User Connection Type 2 Double Ferrule Tube Fitting Connection Size 2 Specified by User Handle Type Nylon-Stainless Steel Insert Handle Color Black Packing Material PTFE

$113.79 - $213.36

Oxone PS-16 Monopersulfate (Non-Chlorine Shock)

OxoneTM PS-16 Monopersulfate | Non-Chlorine Shock Oxone PS-16 Compound is used as an active ingredient in disinfectant formulations (not registered as a biocide in USA), and as an oxidizing agent in other formulations, such as pool & spa non-chlorine shock oxidizers, denture cleansers and laundry bleaches. The grade is also used as a wet strength resin paper repulping aid, metal surface treatment agent, selective oxidizer in chemical synthesis, wool shrink-proofing treatment, waste water treatment and odor control agent. Applications: Water Treatment: It can be used to treat water, including drinking water and pool & spa water, due to its ability to kill bacteria and neutralize contaminants. Cleaning and Sanitization: It's used in various industrial cleaning products, especially for disinfecting surfaces or purifying air and water. Oxidation Reactions: In chemical processes, Oxone PS-16 can be used as a strong oxidizing agent to break down pollutants or aid in chemical synthesis. Active Ingredients: Potassium Peroxymonosulfate (KHSO₅) - 45% Other Ingredients - 55% Total -100% Bag Dimensions: 21"x14"x4" (55.1lbs) Chemical Formula: KHSO₅·KHSO₄·K₂SO₄ Molecular Weight: 614.8 g/mol CAS Registry Number: 70693-62-8, 7646-93-7, 7727-21-1 Appearance White Granules Odor: Odorless Density 2.35 g/cm3 (68 °F / 20 °C) Boiling Point: None Solubility in water: Highly and Readily Soluble at 297–357 g/L at 22°C (72°F) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H302, H314 GHS Precautionary Statements P260, P264, P270, P280, P301 + P312 + P330, P301 + P330 + P331, P303 + P361 + P353, P304 + P340 + P310, P305 + P351 + P338 + P310, P363, P405, P501 UN Identification Number: 3260 Proper Shipping Name: Corrosive solid, acidic, inorganic, n.o.s. (Monopersulfate Compound) Transport Hazard Class: 8 Packing Group: II DOT Placard: Oxone PS-16 Monopersulfate (SDS)

$392.58

You have seen 1152 out of 1737 products