Alcohol Extraction

ExtractCraft Source Turbo

Source Turbo Extractor by ExtractCraft Introducing the Source Turbo, with improved processing time, Turbo Mode, altitude-specific tuning, and upgraded crucible design. Perfect for at-home botanical extractions and easy to use with Bluetooth smart-device app (app is not necessary for operation), Source Turbo is the only at-home extraction appliance in the world that is made simple, smart, and safe for all your extraction needs. A Source Turbo purchase includes the full unit similar to photo (phone not included) but with the newly designed nickel-plated crucible! It also includes an ice tray for cooling the lid and ships in discreet packaging. Disclaimer: Do not use 710 extraction solvent with Extract Craft Products. They can only be used with pure ethanol. Perfect for At-Home Botanical Extraction Source Turbo makes it easy for you to quickly and safely create botanical oils and concentrates in the comfort of your own home, and comes equipped with altitude-specific tuning, so you're good to go whether you're in the mountains or on the beach. Request Source Turbo at your local hydroponics store or smoke shop, or check out our Store Locator for a nearby retailer currently carrying Source Turbo. Be a trendsetter and show all your friends how the pros do it! ExtractCraft Source™ Turbo - USER MANUAL **iPhone pictured not included.

$872.51$829.95

Cryogenic 45L Centrifuge Extractor Kit

Cryogenic 45L Centrifuge Extractor Kit EXPECT 3-WEEK LEADTIME Cryogenic 45L Centrifuge Extractor Kit Overview: The BVV Cryogenic 45L Centrifuge Extractor Kit is a modular closed loop alcohol extraction system with low temperature extraction in mind. It features low temperature rated (-60°C) components including PTFE envelope gaskets, pneumatic diaphragm pumps and cryogenic rated ball valves for longevity. The centrifuge controller and motor are EX rated and come with supporting documents making it easier to get approved for operation. Load centrifuge bags with 8-15lb (10lb avg.) biomass and line them up for an efficient extraction process. This system makes repeatability easier by letting the operator control extraction parameters including soak/agitation time, spin dry time, target alcohol temperature, and different pore material bags and filtration socks in our Pressure Filtration System (PFS). The system also allows operators to re-direct the first wash back to the holding vessel to re-chill if needed and go for a second extraction. This allows full use of alcohol’s extraction ability and minimize time spent recovering solvent in a rotary evaporator or falling film. Users will have to dial in their parameters and washes based on biomass potency. Low temperature extraction leads to less refinement after the extraction process. Inline PFS allows for fine particulate refinement down to 1µm. Higher potency will require further post processing for the removal of unwanted compounds. NOTE: CHILLER AND AIR COMPRESSOR NOT INCLUDED IN THE KIT. CALL IN FOR RECOMMENDED CHILLER AND AIR COMPRESSOR. Insulation: Insulation package is included with the order but does not come installed upon arrival. Insulation included are straight tubing, tees, and elbows. BVV can install insulation as an add on prior to shipping the system out. This will also include color coordinated zip ties that help assembly process. Assembly diagrams will also be included with the system. Installation requires taping seams cutting tubing to length, and zip tying tees and elbows. Holding vessel and centrifuge are vacuum insulated via the jacket. Supporting documents included: Standard Operating Procedure for CF45L-CRYO-01 Centrifuge Wiring Instructions CF45L-CRYO-01 Manual CF45L-CRYO-01 Assembly Diagram Centrifuge Controller EX Certificate Centrifuge Motor EX Certificate Pneumatic Pump specification sheet with operating pressure/flow chart CALL IN TO SCHEDULE A FULL PRESENTATION WITH ONE OF THE CRYOGENIC 45L CENTRIFUGE EXTRACT KIT. QUESTIONS CAN BE ANSWERED BY OUR ENGINEERING TEAM. Specifications Centrifuge Controller Power Requirements 220v 1PH 60Hz, 20A Circuit Liquid Transfer Pumps Pneumatic (Compressor Required) Drum Volume 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Centrifuge Bags Included 1 of Ea: 1, 10, 50, 100, 200 Micron Max Biomass Capacity 15lbs (6.8Kg), Recommended 10lbs Solvent Capacity per Run 17 Gallons Centrifuge Speed 1500 RPM Centrifuge Weight 794lbs (360Kg) Overall System Dimensions 12'6" x 13'8" x 71" (3810mm x 4166mm x 1804mm) **with chiller next to system System Temperature Rating -60C (-76F) Material in Contact with Solvent and Extract PTFE envelope, Silicone, 304SS, BIIR(butyl) *FDA & USDA compliant Footprint: NOTE: CHILLER INCLUDED IN EXTRACTION SPACE WILL NEED TO BE APPROVED FOR USE IN C1D2 SPACE. AIR COMPRESSOR FOR PNEUMATIC PUMPS NOT INCLUDED IN DIAGRAM.

$72,354.53

BVV 6" Turnkey Falling Film Evaporator

BVV 6" Turnkey Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation · The certified model is 22 State certified by PRV Engineers and includes an Infield Verification by PRV Engineers within the purchase price. States include but are not limited to: Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Illinois, Kansas, Louisiana, Maine, Massachusetts, Missouri, Nevada, North Carolina, Oklahoma, Oregon, Texas, Vermont, Washington, West Virginia, and Wyoming Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes Hubbell Process Water Heater Heater for Heat Exchanger Column (Evaporation) 240V 3-Phase 87 36kW Heating Capacity Taco ECM High-Efficiency Circulator Water Circulator for Heater 115V 1-Phase 2.5 Max flow rate 52GPM 10hp Polyscience Chiller 230v Chiller for Heat Exchanger Column (Condensation) 230V 3-Phase 78 38.7kW Cooling Capacity 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 174.4 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$102,147.57 - $106,687.46

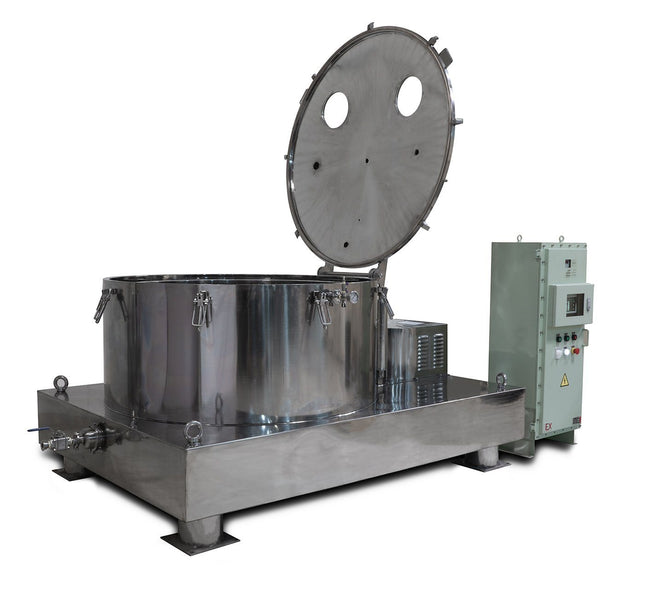

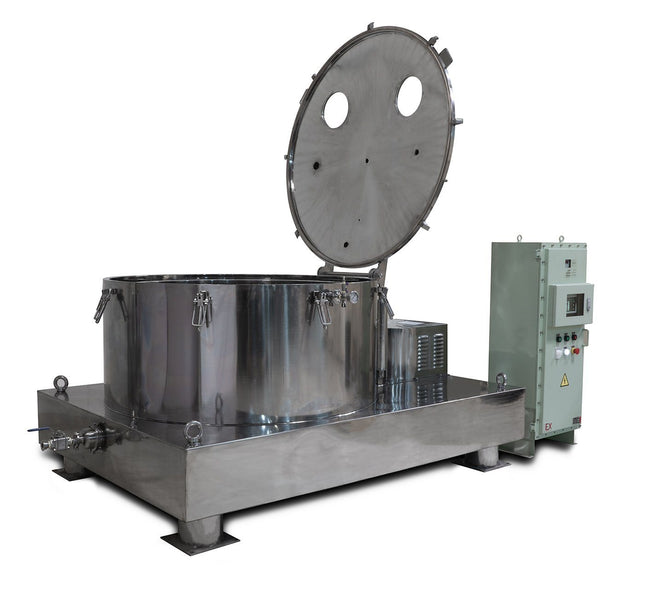

45L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 15LB Max Capacity

45L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1500 RPM with Gradual Speed Stepping 566 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation Specifications Capacity 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Max Capacity 15lbs (6.8Kg) Speed 1500 rpm Separation Factor 566 Electrical 240V 1Ø Weight 794lbs (360Kg) Exterior Dimensions 50" x 27.6" x 28.7" (1280mm x 700mm x 730mm) Viewport Diameter 5.5" Connection Size(s): 2" Tri-Clamp Drain Port 1" Tri-clamp Side Port X 2 1" Tri-Clamp Top Port 1.5" Tri-Clamp Top Port 1/4" FNPT Top Port KF25 Top Port

$27,664.97

160L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 55LB Max Capacity

160L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1200 RPM with Gradual Speed Stepping 643 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation Specifications Capacity 160L Drum Dimensions 31.5" (800mm) Diameter x 12.6" (320mm) Depth Speed 0-1200r/min Weight 3307lbs (1500KG) Exterior Dimensions 51.2" x 72.8" x 43.3" (1300 x 1850 x 1100mm) Material 304 Stainless Steel Motor Power 7.5KW Explosion Proof - 220v 60Hz 3 Phase

$46,108.28

280L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 85LB Max Capacity

280L Ethanol Wash/Dry Centrifuge NOTE: This item currently has a 2 week lead time. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it and will also ship via freight only. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1000 RPM with Gradual Speed Stepping 559 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation Specifications Capacity 280L Drum Dimensions 39.4" (1000mm) Diameter x 14.17" (360mm) Speed 0-1000r/min Weight 4,188lbs (1900KG) Exterior Dimensions 59.06" x 82.68" x 45.28" (1500x2100x1150mm) Material 304 Stainless Steel Motor Power 11KW Explosions Proof - 220v 60Hz 3 Phase

$51,073.79

475L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 150Lbs Max Capacity

475L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift with a 6000lb+ rating to lift it. Due to the size and weight of this item a custom freight quote will be required. If purchased, BVV will contact the customer to provide shipping options and their price. Confirming logistics will require a 2-3 week lead time. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 800 RPM with Gradual Speed Stepping 430 Separation Factor Multiple Connection Ports/Sizes. High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1.5" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation Specifications Capacity 475L Drum Dimensions 47.24" (1200mm) Diameter x 16-3/4" (425mm) Deep Max Capacity 440lbs (200Kg) Speed 800 rpm Separation Factor 430 Electrical 240V 3Ø Weight 5600lbs (2540Kg) Exterior Dimensions 85" x 65" x 49" (2150mm x 1650mm x 1250mm) Viewport Diameter Dual 9" Viewing Ports Connection Size(s): 4" Tri-Clamp Drain Port 1.5" Tri-clamp Jacket Port x 2 1.5" / 2.5" Tri-Clamp Top Ports 1/4" FNPT Top Port KF25 Top Port

$56,039.29

BVV 6" Falling Film Evaporator

BVV 6" Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 6.9 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$49,655.07

Solvent Recovery Kit - 2 Gallon (Compares to ExtractCraft Source Turbo)

Solvent Recovery Kit - 2 Gallon The BVV Solvent Recovery Kit makes it easy for anyone to recover and reuse their extraction solvent. The kit uses a vacuum pump to lower the boiling point of the solvent, then will use a cooling source such as ice or dry ice to turn the vaporized solvent back into liquid form. This kit has a few different seals, be sure that all materials are compatible with your solvent. These materials include: Viton (FKM) Silicone EPDM / Butyl Please verify before using that all these materials are compatible with your solvent. For an easy resistance chart please visit the Cole Parmer link below: https://www.coleparmer.com/chemical-resistance What's included: No Pump BVV-2G Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel Induction Heating Plate With Pump BVV-2G-V40 Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel Induction Heating Plate Chemically Resistant Vacuum Pump No Evap/ Pump BVV-2G-NEV Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel LID with Universal Gasket *NOTE: This option will fit any pot with an outer diameter of 6.5" - 10.5" Not included in the kit, you will need: Ice Tray Ice Bucket Ice or dry ice A 5 gallon bucket and disposable aluminum catering tray will suffice, however a container with a drain plug or valve would be ideal to easily drain the water produced throughout the process. This kit requires a vacuum pump to operate, we would recommend a chemically resistant diaphragm vacuum pump. We include a 1/4" JIC and 1/4" barb connection to connect to your vacuum pump. The included hosing is 1/4" ID Tygon tubing to easily attach to a barbed vacuum pump. Running the Unit Caution: Unit uses flammable solvents. Use caution while operating unit. ALWAYS OPERATE IN EXTREMELY WELL VENTILATED AREAS Place your solution into the Evaporating Vessel. This can be done by: removing the lid and pouring the solution into the vessel Using the vacuum pump to suck the liquid mixture through the Liquid Inlet Port. Using this method, you can use a Micro-Cap filter in-line to remove solid particulate. Close the Liquid Inlet Port valve and Air Inlet valve Add ice to the bucket and tray. A drain valve built in to the ice bucket and tray would help to drain water later in the test. Open the Vacuum Pump valve and turn on the Vacuum Pump Turn on the Heat Plate. An induction heating plate is recommended Replace ice as needed throughout the run When recovery is completed, close the Vacuum Pump valve and turn off the Vacuum Pump. Open the Air Inlet valve and release the vacuum pressure from the chamber. Use the included micron filter to prevent contaminants from entering the vessel. Turn off the Heat Plate and allow the solute in the Evaporating Vessel to come down to a safe temperature. Removing the solute is easiest when it is still warm. Remove the solvent from the Receiving Vessel. Once the kit is cooled down, use clean ethanol to wipe down the sealing surfaces for the next run. For a more detailed operating procedure please be sure to check out this website: HOME EXTRACTION BY ICHIBANCRAFTER : https://extractcrafter.com/2022/05/10/diy-vacuum-still-part-2-putting-together-and-operation/

$663.96 - $3,508.49