Shop BVV

20L Neocision ETL Lab Certified Rotary Evaporator

20L Neocision ETL Lab Certified Rotary Evaporator The 20L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 20L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Model 20L NEOCISION Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 0-120 RPM Set Temperature 0-99C / 0-210F Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 20L (20000ml) Receiving Flask Capacity 10L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Evaporation Capacity Alcohol >/= 12 L/H Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 4.1 Dimensions 49 x 24 x 83 in. Weight 155 lbs Vacuum Connection 10mm / 3/8 in. Barb Condenser Connection 10mm / 3/8 in. Barb Warranty 1 Year excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$9,251.74

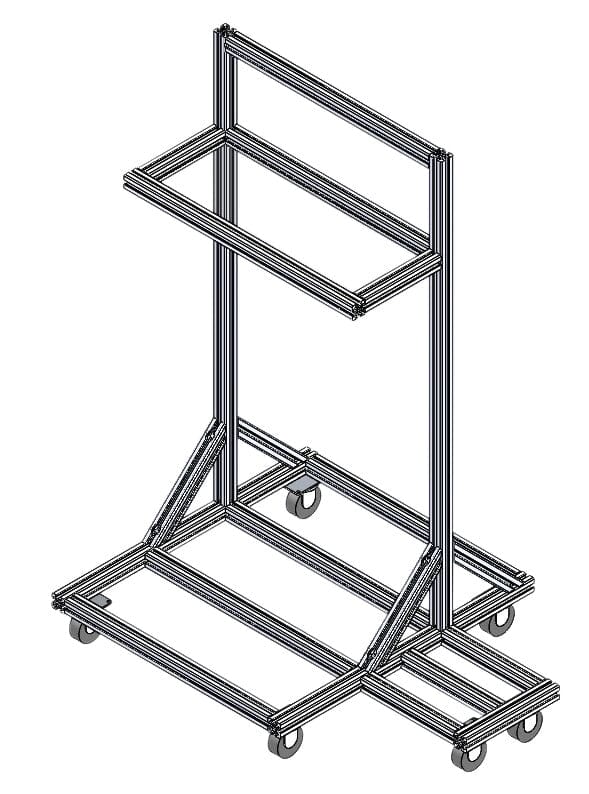

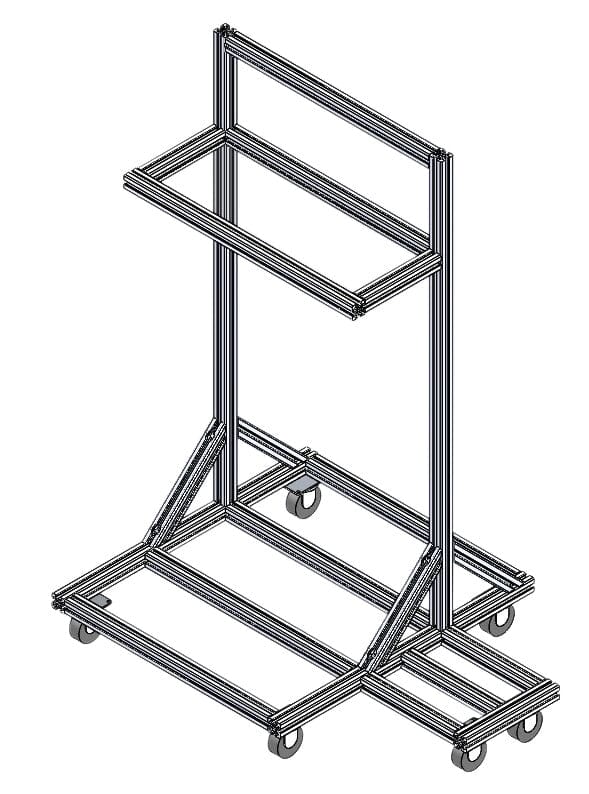

Extraction RACK # 2

BVV™ Extraction RACK # 2 (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges. Extraction Rack 2 Technical Drawing This rack fits the following BVV™ Extraction Systems: 8.5LB Athena 2LB Little Icarus 5LB Icarus Specifications (Does not include height with casters) Main Base Dimensions 33" X 30" Vertical Dimensions 33" X 48"

$1,067.51 - $1,352.18

Carbon Chemistry APG Granular (ZeoClear Y)

Carbon Chemistry APG Granular (ZeoClear Y) A selective zeolitic clay adsorbent designed for precise separation control. This thermally activated attapulgite-zeolite composite features a unique alkaline surface chemistry that provides measured adsorption rates, making it ideal for gentle refinement processes. Its carefully engineered pore structure and granular stability allow for controlled removal of specific compounds while preserving desired characteristics of the process stream. Key Features: Micron Size 250-595um Attapulgite granular media, alkaline medium Easy handling, fast flow, color improvement General product improvement with high contaminant absorptivity Color Remediation In-Line Filtration Hot Scrub Recirculate Granular Media FAQ: How do I use granular media? Zeolite adsorbents can be used inline during extraction with LPG solvents or in a hot scrub with non-polar solvents of higher BP like Heptane Is this a replacement for powders? The answer depends on what your processing goals are e.g. color removal, pesticide remediation, etc. Each adsorbent for filtration media will have its own unique set of properties including pH, pore size, polarity, surface area that make certain adsorbents more suitable to certain uses. Can I mix granular media and powders? Yes, you can either mix powders with granular media or place the granular media on top a bed of powdered media. This will however result in a more restricted flow which will require additional pressure to pass your solution through your filter cake. Do I need to bake the media? Media does not need to be baked prior to use but can be only superficial water will be removed which may improve performance. To remove superficial moisture, bake for 8hrs at 200C (392F) How do I know how much media to use? This will depend on a few variables such as the amount of your starting material, the age of your starting material, and desired color of your final product. How does the media need to be stored? before and after use. Before use; Keep container tightly closed and dry; store in a cool place. After use; Store in a well-ventilated area, this media is saturated with flammable/explosive solvent and can self-ignite if not not handled properly. Is the media safe to handle without PPE (Personal Protective Equipment)? Breathing must be protected when large quantities are decanted without local exhaust ventilation. When workers face exposure to dust exceeding the occupational exposure limits they must use appropriate certified respirators. Wear a NIOSH-certified (or equivalent) particulate respirator. What micron size filters are required? / The media is larger but are there fines? The media might be large but there are fine dust particles (about 5 million per lb.) that can get carried away in your solution and require separation. We suggest stacking a 5-micron filter on top of a 1-micron filter which will help keep your flow slow as well as filtering out any fine dust particles. The media didn't work, what did I do wrong? There is an exceptionally good chance you did not restrict your solvent flow enough. Try again with a much slower flow through your filter. Another variable you might consider adjusting is solvent temperature. Colder solvent will pull less lipids and waxes which can impede the efficiency of the adsorbent. Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack

$56.93 - $11,386.76

10 Gallon Resin Trap Vacuum Chamber

10 Gallon Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 10 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 15" Tall x 14" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$444.08

3 Gallon Stainless Steel Resin Trap Vacuum Chamber

3 Gallon Stainless Steel Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 3 Gallon Stainless Steel Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 10-7/8" Tall x 9" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water.• ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$213.50

Graco Pneumatic Diaphragm Pump for Ethanol

Graco Pneumatic Diaphragm Pump for Ethanol This air driven diaphragm pump is designed to be used with ethanol filtration, pumping processes, and BVV Centrifuges. It's unique rugged design can withstand temperatures from -40C to -80C. The inner diaphragms are made out of PTFE and the main body of the pump is made out of 316 Stainless Steel. The pre-built version comes with a 0-160 psi pressure gauge, mini ball valve, and 1.5" Tri-Clamp connections for the inlet and outlet ports. Specifications -40C -80C Power Source Air Operated 100PSI 28CFM Certification Required No Certifications ATEX Fluid Section Material Stainless Steel Pump Inlet/Outlet 716-3/4 Inc, 16gpm (19mm, 61lpm) Center Section Polypropylene Standard Air Vale (NPT) Porting SST Standard Porting (NPT) Seats 316 SST Balls PTFE Diaphragms PTFE PTFE Overmolded Manifold O-rings PTFE Max Operating Temp. 220°F (105°C)

$3,672.23 - $5,116.92

Triclamp / Tri Clover Y

Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1" or 1.5" Triclamp Unique Y Connection Disclaimer: All Stainless Steel Parts bought seperately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system"

$54.09

5 Gallon Refinement Filter

The BVV™ 5 Gallon Refinement Filter is a stainless steel filtration system that provides large scale, high flow filtering, with greatly improved functionality compared to a traditional Buchner filter. Utilizing a collection base for vacuum assistance and storage of material, the Refinement Filter allows for benchtop filtration with a longer lifespan and ease of use. Key Features: Stainless steel design for greater thermal conductivity and improved lifespan Easy to clean and disassemble with Tri-Clamp stainless steel parts Small tabletop footprint with wide mouth design Secondary collection vessel for vacuum and storage of material Liquid dip tube for direct injection into rotary evaporator after filling Key Specifications: Large 6" Diameter x 12" Long Dewaxing Column 20 Liter Collection Base 5 micron Sintered Stainless Steel Filter Disc 100 Pack of 6" Ashless Filter Paper (BIO-1-180) Dedicated 3/8" Vacuum Valve Dedicated 3/8" Dip Tube Valve Silicone gaskets with high alcohol resistance 3/8" Stainless steel hose barb connections Polycarbonate sights for easy viewing 2" Tri-Clamp Short Sight Glass for Flow Viewing Operation Instructions: Before beginning filtration, place refinement filter in freezer for best thermal conductivity Secure ashless filter paper with filter plate ring Place collection base on floor and connect tubing from refinement filter to to a vacuum pump Attach vacuum system to the dedicated vacuum valve Begin to pour solution into filter Close dedicated dip tube valve and start vacuum Once solution has been completely filtered, stop vacuum system and disconnect from dedicated vacuum valve Connect dedicated dip tube valve to injection valve on rotovap Begin rotovap procedure Open dedicated dip tube valve and begin injecting filtered solution into rotovap

$2,135.02

150 Liter Collection Vessel with Internal Coil, Coned Bottom, and Baffle in Jacket

150 Liter Collection Vessel with Coned Bottom and Baffle in Jacket (Note: this unit comes bare and does not include any fittings besides the legs with casters.) ***Note: This item will ship via freight ONLY. This massive 304 Stainless Steel Jacketed vessel can hold up to 150L of water (~40 gallons) and multiple connections on top of the vessel and lid. The outer jacket has large ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 21.5L or 5.68 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily. This Vessel is rated to 100 PSI MAX

$4,554.70

TRS21 Upgraded Compressor head SS ¼” SAE 45D IN and OUT fittings

BVV-9-1 Included in this kit: TRS21 compressor head SS ¼” SAE 45D IN and OUT fittings, Viton o-rings. Use these fittings to replace the OEM brass fittings on your TRS21. The SS fittings minimize and help eliminate bacterial growth in the recovery process.

$39.85

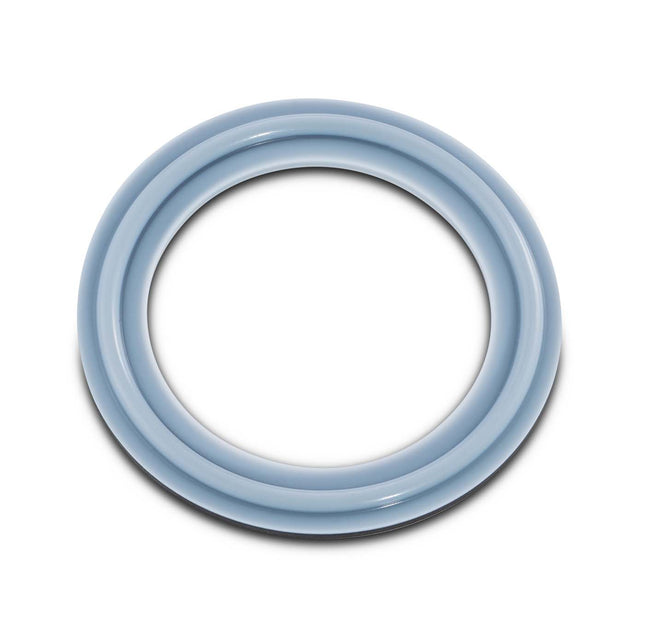

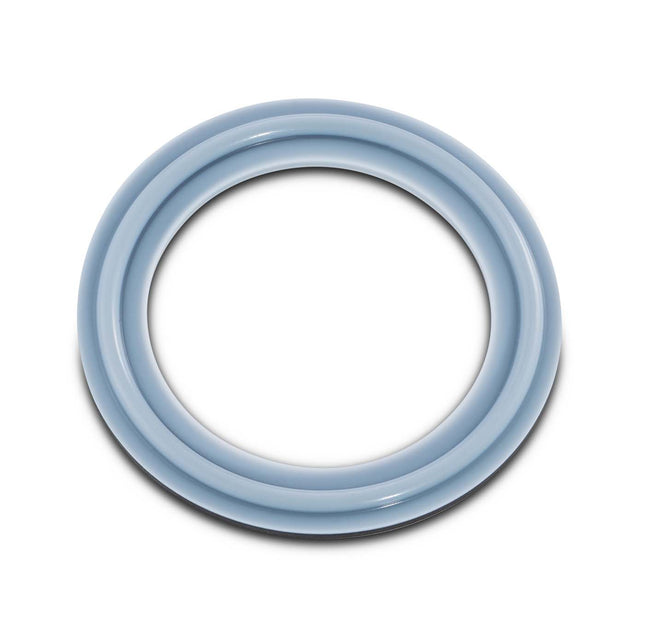

Tef-Flex PTFE / EPDM Unitized Sanitary Tri-Clamp Gasket

Tef-Flex Sanitary Tri-Clamp Gasket Tef-Flex: A Tef-Flex sanitary gasket’s contact surface is a layer of PTFE grafted to an EPDM rubber inner core. This totally bonded construction provides an exceptionally pure and incredibly flexible seal. By grafting the elastomer with a layer of PTFE, Tef-Flex will behave like an elastomer but will prevent product contamination, service interruptions and clean-up costs associated with traditional elastomer seals. The PTFE grafted elastomer in a Tef-Flex sanitary gasket will maintain I.D. without re-torquing or leaking. Key Features: Excellent resistance to almost all chemicals Excellent Temperature Range Excellent Cleanability due to PTFE (Teflon) Excellent Flexibility Sizes Available: 1.5" 2" 2.5" 3" 4" Chemical Compatibility: Butane A - Excellent Propane (liquified) A - Excellent Alcohols: Amyl A - Excellent Benzyl A - Excellent Butyl A - Excellent Diacetone A - Excellent Ethyl A - Excellent Hexyl A - Excellent Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl A - Excellent Propyl A - Excellent Disclaimer: BVV Recommends no more than a -40F Operating Temperature and is not responsible for the user running their system with incompatible chemicals.

$27.04 - $65.47

Tygon 2475 Smooth Bore High Purity PVC Tubing - 1/2"

1/2" Tygon 2475 Smooth Bore High Purity PVC Tubing Formulation 2475 Tygon tubing is the ultimate in performance PVC tubing this tubing is free of plasticizers, made of FDA listed materials, rated for vacuum, and has a minimum temperature range of -90°F all the way up to 120°F. This tubing is meant for sensitive transfer fluids, pharmaceutical solutions, biotechnological applications because of its high performance and smooth bore. Formulation 2475 also resistance damage from aggressive chemical cleaners and sanitizers and contains no plasticizers which could contaminate the transferred fluids. The smooth non-wetting inner bore prevents the build-up of particulates and limits absorption and adsorption to further preserve fluid purity and integrity. When burned for disposal this tubing will not release any hazardous byproducts such as chlorine and will only release carbon dioxide and water for a less toxic means of disposal it can also be sterilized with ethylene oxide (ETO), chemicals, or radiation. The tubing has a working temperature of -90 to 120°F and a durometer of 70a and a pressure rating of 29.9 psi at 72F. this tubing meets U.S. Pharmacopoeia (USP) Class VI criteria for medical grade plastic materials and U.S. Food and Drug Administration (FDA) 21 CFR 177.1520 criteria for food contact for quality assurance. Tygon 2475 Brochure Key Features: Plasticizer-free plastic tubing for transferring fluids in medical, pharmaceutical, and biotechnological applications Clear Tygon formulation 2475 plastic for visually monitoring transfer of fluids Smooth bore to allow full drainage and prevent absorption and particulate build-up for preserving fluid integrity Working temperature range of -90 to 120°F and durometer (hardness) of 70A Meets USP Class VI and FDA CFR21 177.1520 standards for quality assurance Vacuum Rated to 29.9inHG Specifications ID 1/2" OD 3/4" Wall Thickness 1/8" Temperature Rating -90° to 120°F Vacuum Rating 29 in. of HG @ 72°F Durometer 70A Hardness Rating Soft Flexibility Very Flexible Bend Radius 1-1/2" Maximum Pressure 29psi @ 72°F Compatible Tube Fittings Barbed Formulation 2475 Standards Meets USP Class VI FDA CFR21 177.1520 standards for quality assurance Chemical Resistance: Excellent Acetic Acid (10% in Water) Acetic Acid (30% in Water) Deionized Water Hydrochloric Acid (10% in Water) Hydrochloric Acid (30% in Water) Hydrogen Peroxide (10% in Water) Hydrogen Peroxide (30% in Water) Isopropyl Alcohol Methanol (Methyl Alcohol) Nitric Acid (Up to 50% Concentration) Phosphoric Acid (25% in Water) Phosphoric Acid (85% in Water) Sodium Hydroxide (Caustic Soda) (10% in Water) Sodium Hydroxide (Caustic Soda) (30% in Water) Sodium Hypochlorite (Bleach) Sulfuric Acid (10% in Water) Sulfuric Acid (30% in Water) Moderate Acetone, Methyl Ethyl Ketone (MEK) Vegetable Oil Not Recommended Mineral Oil Note Chemical compatibility must be determined by the customer based on the conditions in which the product is being used, including the presence of other chemicals, temperature, and consistency. Safety Data SDS RoHS Compliant

$64.05 - $640.51

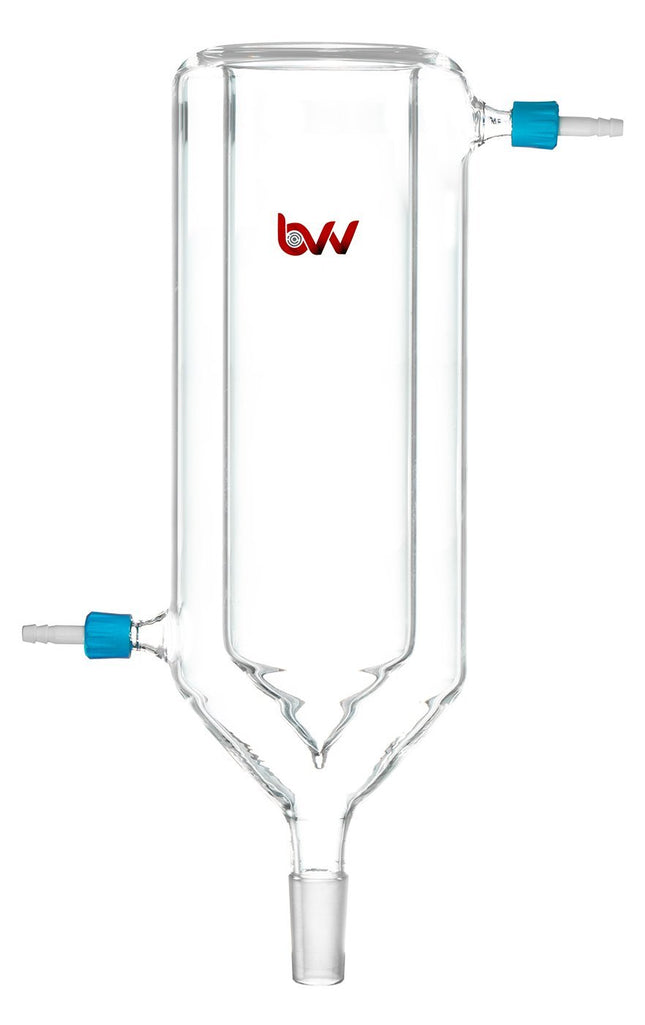

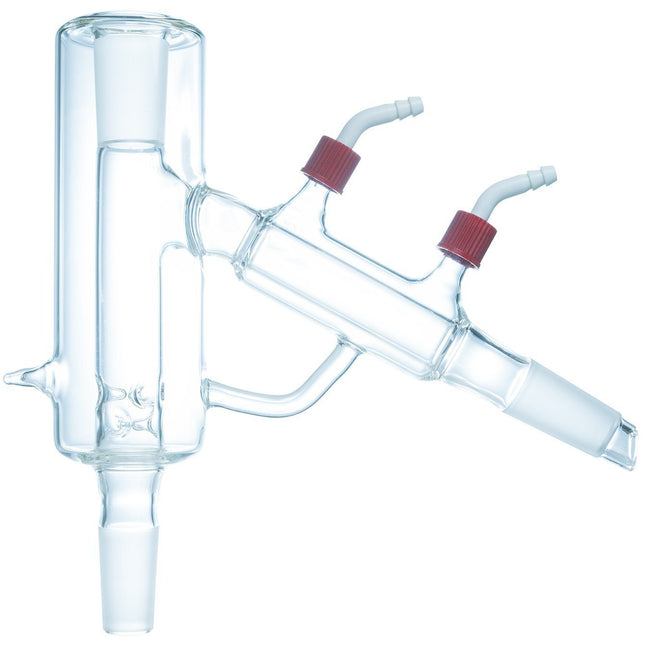

2L Electric Lift Condenser

Condenser for Best Value 2L Electric Lift Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$355.84

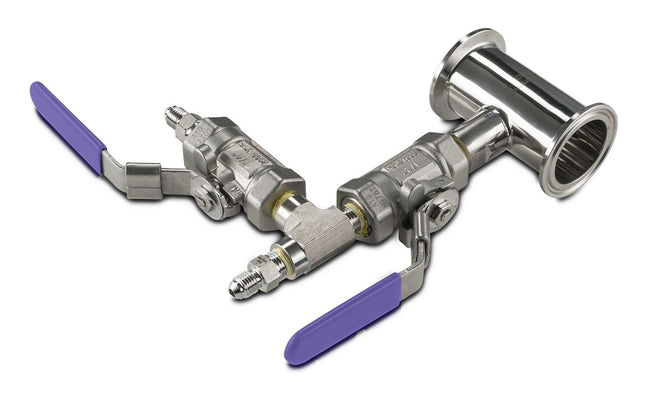

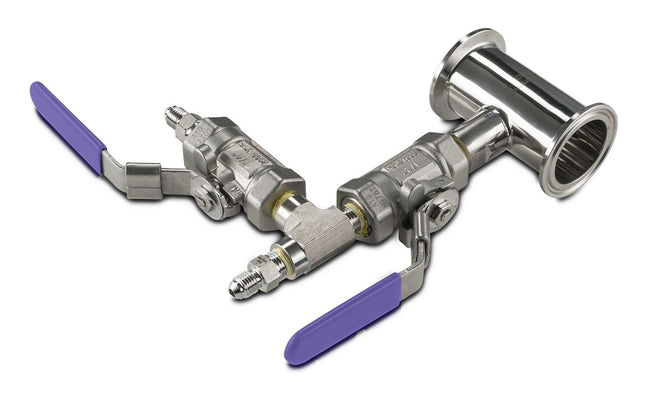

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves (This part is fully assembled and Nitrogen Tested for Leaks at BVV™) This BVV™ BIFLOW Manifold is fully assembled and nitrogen tested for leaks at our warehouse. This manifold comes with 2 BVV 316SS Full Bore Valves with (2)1/4" 37° JIC Flares. This manifold is made out of 304 stainless steel with a Tri-Clamp end connection on either side. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel 1.5" or 2" Tri-Clamp Connections Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" 37° JIC Tri-Clamp Size(s) Selectable through Dropdown Nitrogen Tested Yes

$303.17 - $307.44

1.5" Fully Jacketed Tri-Clamp x 8" 90 Degree Bend

1.5" Fully Jacketed Tri-Clamp/ Tri Clover x 8" 90 Degree Bend This 1.5" Fully Jacketed Triclamp/ Tri Clover 90 Degree bend is extended out to 8" end to end to add extra length to the fitting. It is made out of 304 Stainless steel with a high polish interior and exterior and has (2) 1/2" FNPT ports on the outer jacket and is made to circulate fluid through the outer jacket to either condense or heat up the internal vapors or liquids. Specifications Material 304 Stainless Steel Connection Size 1.5" Tri-Clamp 1/2" FNPT Length 8" Standard 3A High Polish

$334.49

UL Listed BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 21.2CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 1100 Watts Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 95lbs Shipping Weight: 105lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$4,981.71

Best Value Vacs 3 Gallon WIDE Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Best Value Vacs 3 Gallon WIDE Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 3 Gallon WIDE Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$424.16 - $666.13

Best Value Vacs 3 Gallon Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Best Value Vacs 3 Gallon Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 3 Gallon Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 10-7/8" Tall x 9" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$424.16 - $666.13

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$569.34

Habonim Cryogenic Ball Valve

Habonim Cryogenic Ball Valve BVV™ Habonim Cryogenic Ball Valve - Data Sheet General Specifications Body Material CF8M Seat Material TFM Ball Material 316 SS Pressure Class 800 Temperature Range -60°C to 200°C

$213.50 - $711.67

Best Value Vacs 3 Gallon WIDE Stainless Steel Vacuum Chamber W/GLASS LID

3 Gallon Wide Stainless Steel Vacuum Chamber W/GLASS LID (Comes with 2 Year Limited Warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$216.35

Best Value Vacs 3 Gallon SS WIDE SIDEMOUNT Vacuum Chamber and Vacuum Pump Kit

Best Value Vacs 3 Gallon SS WIDE SIDEMOUNT Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 3 Gallon SS WIDE SIDEMOUNT Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is the only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$424.16 - $666.13

KF-25 Y Bellow

This Unique 304 Stainless Steel KF-25 Y Bellow has 3 attachment points for KF-25 fittings and 2 flexible ends and 1 rigid end that let the user position them the way that best suits their operation. It has an overall length of 17" and a width of ~16".

$298.90

Isopropyl Alcohol 70% Tech Grade

Isopropyl Alcohol 70% Technical Grade Isopropyl alcohol is a fast-evaporating solvent and industrial cleaning agent, intended for industrial or professional use only. It can be used as a solvent for gums, shellac, and essential oils. Can be used as a fuel additive. Isopropyl Alcohol (liquid) - 70% Purity / 30% De-Ionized Water Shelf Life - 5 years Chemical Formula: C3H8O Molecular Weight: 60.096 g/mol CAS Registry Number: 67-63-0 Appearance Colorless Liquid Odor: Pungent Alcoholic odor Density 0.858 g/cm3 @ 20 - 25 °C (68 - 77 °F) Boiling Point: 80.9 - 83.2 °C (177.6 - 181.8 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319, H336 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P261, P264+P265, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P319, P337+P317, P370+P378, P403+P233, P403+P235, P405, and P501 UN Identification Number: 1219 Proper Shipping Name: Isopropanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Isopropyl Alcohol 70% Tech Safety Data Sheet (SDS) Isopropyl Alcohol 70% Tech Certificate of Analysis (COA)

$19.93 - $854.01

1" FNPT X 1.5" Tri-Clamp Top Cap

1" FNPT X 1.5" Tri-Clamp Top Cap These tri-clamp end caps: Have a 1" Female NPT connection Are made of 304 stainless steel

$28.47

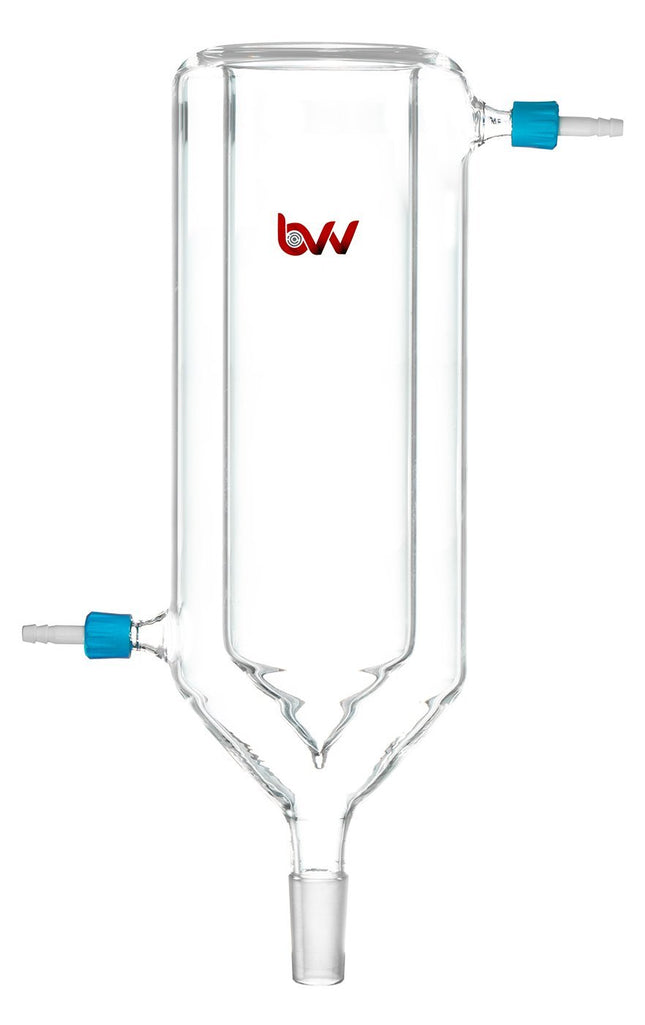

Dewar Glass Cold Trap

BVV™ Dewar Glass Cold Trap This dewar style glass is designed for maximum vapor condensation and it also has a 24/40 bottom joint and (2) GL-14 8mm Hose Barbs *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$355.84$298.90

Glass Vac 3 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit

Glass Vac 3 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 2 Gallon Aluminum Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 9" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC HosePlatinum Cured Silicone PadBlack 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$439.81 - $660.43

Best Value Vacs 3 Gallon SIDEMOUNT Vacuum Chamber and Vacuum Pump Kit

Best Value Vacs 3 Gallon SIDEMOUNT Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent-pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 3 Gallon Sidemount Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 9" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$409.92 - $651.89

5L Neocision ETL Lab Certified Rotary Evaporator

5L Neocision ETL Lab Certified Rotary Evaporator The 5L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 5L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 5L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 110V 50/60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5 - 99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 5L (5000ml) Receiving Flask Capacity 5L (5000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 1800w Dimensions 45 x 32 x 15in Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 1 Year Excluding: Moving Parts Glassware Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,693.38

UL Listed BVV™ Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,700.70

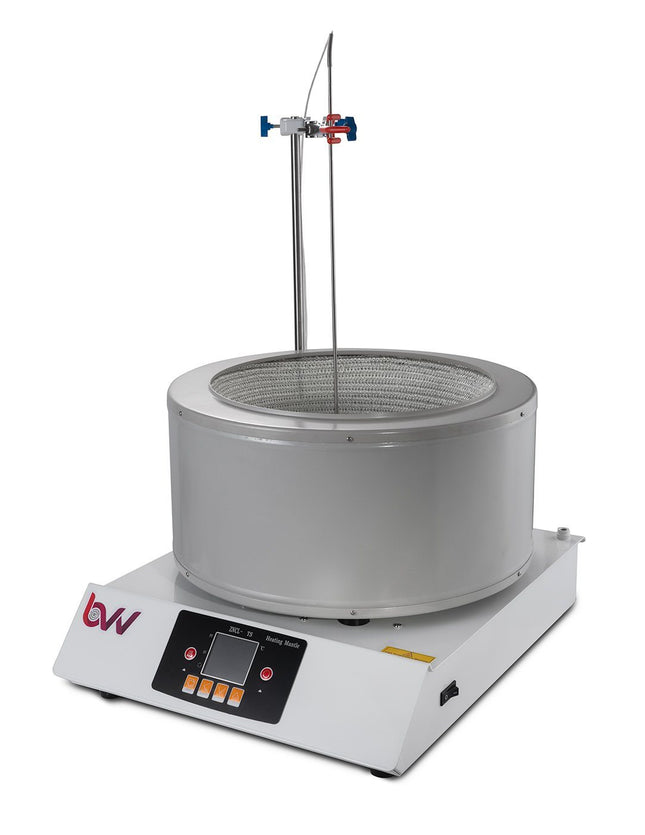

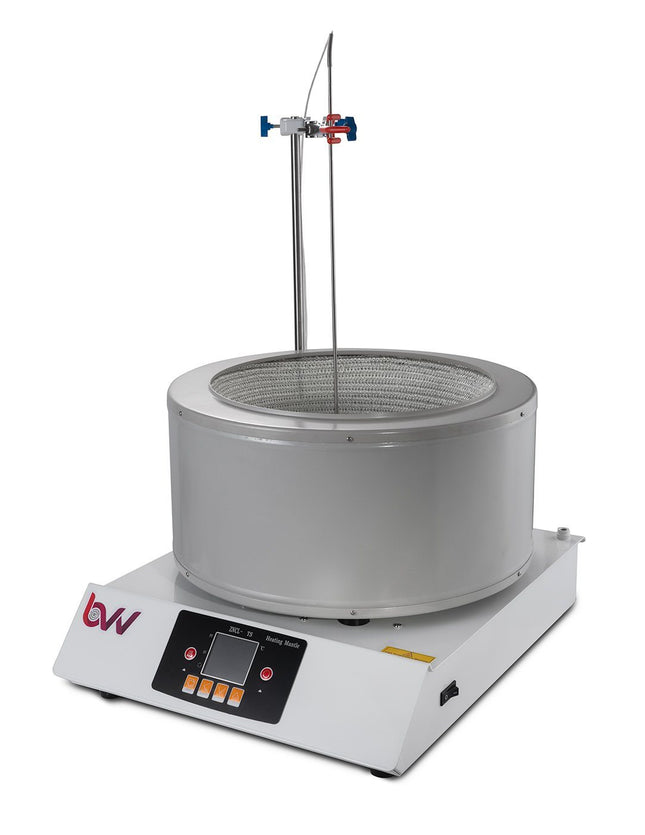

10L Digital Heating and Stirring Mantle

10L Digital Heating and Stirring Mantle Digital Heating and Stirring Mantles give the operator the most precise temperatures and readouts during distillations. These mantles autotune to specific user input to provide consistent results. Each mantle is equipped with large digital display that will give you readouts for both set temperature, actual temperature, and stirring speed. Each mantle also comes with a vertical brace bar and boss head as well as a temperature probe which plugs directly into the mantle. For first time use, the mantle should have an initial burn out done. This will burn off any residual oils used in the production of the insulation rope. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Specifications Capacity: 10L (10000mL) Power Supply: 220V 60Hz Adjustable Rotation Speed: 50-1800 RPM Motor Power: 40W, DC14-24V Heating Power 180-2200W Temperature Control Accuracy: +/- 1C Intelligent Temperature Control: Yes Temperature Range: RT+10-380C Insulation Material: Alkali-free Glass Fiber, temperature resistant up to 450C Shipping Dimensions: 23 x 23 x 16 in. Weight: 20 lbs

$1,636.85

19/26 Inert Gas Valve for BVV™ ECO Rotary Evaporators

19/26 Inert Gas Valve for BVV™ ECO Rotary Evaporators

$42.70

Digital Vacuum Chamber Gauge Upgrade *Wireless

Digital Vacuum Chamber Gauge Upgrade *Wireless After many requests, we have combined our infamous vacuum tight bulkhead with the power of a wireless vacuum gauge that can be a simple upgrade to ANY of our vacuum chamber products or resin traps. For those seeking truly accurate readings at any altitude and wireless monitoring this is the ultimate gauge for any vacuum system!. *To install: All that is required is a 1/2" wrench to remove the original and replace the digital one. The VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$253.36

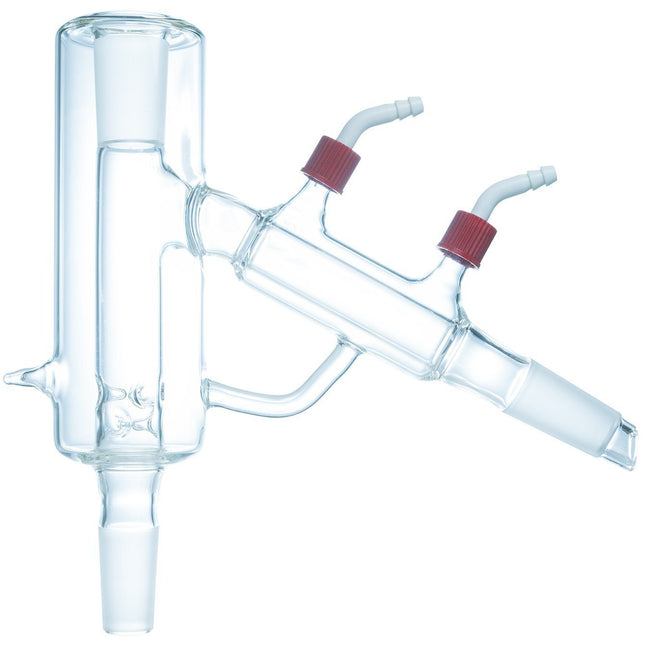

P5V6 Neocision Distillation Head - USA Made

P5V6 Distillation Head P5V6 Distillation Head has 6 sets of vigreux in the distillation column with 34/45 lower joint and 24/40 upper and side joints and includes GL-14 barb connections. MADE IN THE USA Designed for 5 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$782.84

Glass Vac 3 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Glass Vac 3 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 3 Gallon TALL Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 10-3/4" Tall x 9" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$446.93 - $667.55

Glass Vac 8" Diameter LID

Glass Vac 8" Diameter LID Disclaimer: This item Includes Lid and Gasket Only This is a Replacement Lid for the following Vacuum Chambers: Glass Vac 1 Gallon Tall Stainless Steel Vacuum Chamber Glass Vac 1.5 Gallon Tall Stainless Steel Vacuum Chamber

$76.86

20L Digital Heating Mantle