New Products

-

Across International 350C 2000RPM 0.8-Gallon PID Magnetic Stirrer 5.5" Heated Plate

350C 2000RPM 0.8-Gallon PID Magnetic Stirrer 5.5" Heated Plate A magnetic stirrer or magnetic mixer is a laboratory device that employs a rotating magnetic field to cause a stir bar (also called "flea") immersed in a liquid to spin quickly, thus stirring it. A rotating magnet or a set of stationary electromagnets placed beneath the vessel with the liquid may create a rotating field. Since glass does not affect a magnetic field appreciably (it is transparent to magnetism), and most chemical reactions take place in glass vessels (i.e., see beaker (glassware) or laboratory flasks), magnetic stir bars work well in glass vessels. On the other hand, the limited size of the bar means that magnetic stirrers can only be used for relatively small experiments. They also have difficulty dealing with viscous liquids or thick suspensions. Mechanical stirring is typically needed for larger volumes or more viscous fluids. Magnetic stirrers are often used in chemistry and biology. They are preferred over gear-driven motorized stirrers because they are quieter, more efficient, and have no moving external parts to break or wear out (other than the simple bar magnet itself). Because of its small size, a stirring bar is more easily cleaned and sterilized than other stirring devices. They do not require lubricants, which could contaminate the reaction vessel and the product. They can be used inside hermetically closed vessels or systems without complicated rotary seals. Magnetic stirrers may also include a hot plate or other liquid heating methods. Model HP5 Electrical requirements 110V 60Hz 1-Phase, 450 watts Temperature range Ambient to 350°C Heating plate Diameter: 5.5 inches Material: ceramic-coated aluminum Stirring Min. speed: 110 rpm, max. speed: 2000 rpm Motor power: 40 watts Motor type: brush-less DC motor Max. stirring volume: 0.8 gallons (3 liters, water as media) Controller PID control with digital temperature and rotation speed display External thermocouple Type: PT100 Cable length: 35 inches Stainless steel probe length: 11 inches Stainless steel probe diameter: 5 mm Dimensions (WxDxH) Unit: 6.5 x 12 x 4.25 inches, shipping: 16 x 9.5 x 7.5 inches Weight Unit: 9 lbs, shipping: 18 lbs Safety Thermocouple failure protection Built-in fuse protection Certification ETL tested to UL and CSA standards (optional), CE (standard) Warranty One year Standard package Part description Quantity Part image Ai HP5 digital heated magnetic stirrer 1 set External temperature probe Cable Length: 35", Probe Length 11" 1 pc Internal temperature plug 1 pc Boss head 1 pc Stainless steel support rod (16 inches) 1 pc PTFE coated stir bar 2 pcs PTFE-coated magnetic stir bar remover 1 pc 4 prong stainless steel clamp opens to 3 1/2" 1 pc User's manual 1 pc

$525.22 - $732.54

-

50% Hydrogen Peroxide Food Grade H2O2

50% Food Grade Hydrogen Peroxide Our Food-grade 50% peroxide tests at ~50.4%. This the strongest peroxide we offer, next to our 35% Food Grade Peroxide, Our Food Grade 50% hydrogen peroxide is formulated with a special stabilizer package (organophosphonate) that replaces transition metals stabilizers typically found in hydrogen peroxide solutions. Our Peroxide is NSF® Certified. NSF-certified means a product was independently verified for safety, sanitation, and quality by NSF. NSF certification is recognized by health departments, government agencies, and industry associations. *Certified under ANSI/NSF Standard 60 Drinking Water Additives-Health Effects. Dosage levels shall be in accordance with NSF requirements. 55 Gallon Drum weights 548lbs, 270 Gallon Tote weighs 2500lbs. hydrogen peroxide usually loses less than 1% of its initial concentration in one year (0.5% for a 50% solution). 50% Hydrogen Peroxide NSF Food Grade Certificate of Analysis 50% Hydrogen Peroxide NSF Food Grade Safety Data Sheet Chemical Formula: H2O2 Molecular Weight: 34.015 g/mol CAS Registry Number: 7722-84-1 Appearance Colorless Liquid Odor: None Density 1.196 g/cm3 @ 20 °C (68 °F) Boiling Point: 114 °C (237 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H302 + H332, H314, H335 GHS Precautionary Statements P210, P220, P260, P261, P264, P270, P271, P280, P283, P301+P317, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P306+P360, P316, P317, P321, P330, P363, P370+P378, P371+P380+P375, P405, P420, and P501 UN Identification Number: 2014 Proper Shipping Name: 50% Hydrogen Peroxide, Aqueous Solution Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard:

$387.00 - $905.31

-

4" Industrial Plant Material Grinder (Compare to Custom Cones)

BVV 4" Industrial Plant Material Grinder The 4" grinder from BVV will grind your dried plant material into a consistent, manageable size. The grinder is easy to use and can power through over 1.5 lbs per minute or as fast as you can feed it! It can grind dense flower or leafy trim , as long as it is pre dried. This machine will help you keep the trichomes and terpenes in the plant where they should be due to the low operating temperature, in comparison to a common blender or food processor. This Grinder is made of food grade aluminum and stainless steel, and can be broken down for cleaning in a matter of seconds. Very few tools are needed to assemble and operate so you can keep your focus on moving material through this step in your production line. Included with the grinder are two stainless steel screens; 3.8mm small 6mm large Specifications Model Number G400 Voltage 115V / 60Hz Wattage 850w External Dimensions 16" x 9" x 20" Weight 42lbs

$2,971.64

-

NPT Stainless Steel Thermowell

NPT Stainless Steel Thermowell These stainless steel thermowells are the perfect addition to an extraction system allowing the user to probe the internal temperate of a system component to know what temperature it is at. This thermowell feature 304 stainless steel and is 2.5" to 6" long with a 1/4" - 1/2" Male NPT threaded connect and a 1/4"-1/2" female NPT threaded connection on the top of the hex head.

$48.38 - $62.20

-

SHEL LAB SHEL LAB 9.3 Cu Ft Vac Oven SVAC9-2

SHEL LAB - VAC OVEN, 9.3 CUFT, 230V The SHEL LAB Model SVAC9-2 is one of the largest vacuum ovens on the market, with 9.3 cubic feet of capacity. This unit also features a fully programmable Watlow PM9 Plus controller and a cool touch surface. A digital vacuum gauge shows chamber vacuum level in measurements of Torr and m/Torr. The display range is 760 Torr down to 0 mTorr (Maximum permitted end vacuum is 10 mTorr. Leak rate is 30 mTorr in 30 min). A secondary independent high limit controller provides overtemperature safety protection. This unit includes true vacuum valves and has cross-flow ventilation within the oven chamber to enhance total performance. The vacuum oven is secured to a ruggedly constructed mobile stand to create a vacuum pump at the base. Although the oven is not supplied with a vacuum pump, all vacuum plumbing and KF25 connections are provided. The SHEL LAB SVAC9-2 vacuum oven is equipped with a Viton gasket, which provides an excellent combination of high-temperature performance and chemical resistance. When paired with this oven’s deep-draw capacity and large chamber volume, the SVAC9-2 serves as one of the most robust vacuum work stations available on the market. Features include: Watlow PM9 Plus Controller Capable Of 40 Step Ramp And Soak Profiles, Or 4 Files With 10 Steps Per File Stainless Steel Interior Stainless Steel Exterior Option Available (Ideal For Cleanroom Applications) KF25 Fitting Included Built in Vacuum Pump Mount 24 Month Limited Warranty

$32,372.86 $28,487.62

-

SHEL LAB SHEL LAB 4.5 Cu Ft Vac Oven SVAC4

SHEL LAB - VACUUM OVEN, 4.5 CUFT Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications. To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available* (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$18,880.25 - $20,730.96

-

SHEL LAB SHEL LAB 1.67 Cu Ft Vac Oven SVAC2

SHEL LAB - VACUUM OVEN, 1.67 CUBIC FEET Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications.To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$9,889.33 - $10,834.72

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC1

SHEL LAB - VACUUM OVEN, 0.6 CUBIC FEET Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications. To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$8,743.52 - $9,578.34

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC2E

SHEL LAB - ECONOMY VACUUM OVEN, 1.7 CUFT, NON CE SHEL LAB vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. They prevent residue accumulation on products and allow safe drying of materials at lower temperatures than typically required when using convection ovens. These units feature a radiant heating system that optimizes chamber space and provides excellent heat transfer and temperature uniformity. All SHEL LAB vacuum ovens are built with stainless steel chambers that are easy to clean and have exceptional durability. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. A selection of gaskets (for specific applications) and a small benchtop footprint increase the versatility of these ovens. The SHEL LAB economy series of vacuum ovens are outstanding in any application. Features include: Analog Temperature Control Stainless-Steel Interior Built-in Overtemperature Protection 24 Month Limited Warranty

$4,114.68 - $4,505.83

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC1E

SHEL LAB - ECONOMY VACUUM OVEN, 0.6 CUFT, NON CE HEL LAB vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. They prevent residue accumulation on products and allow safe drying of materials at lower temperatures than typically required when using convection ovens. These units feature a radiant heating system that optimizes chamber space and provides excellent heat transfer and temperature uniformity. All SHEL LAB vacuum ovens are built with stainless steel chambers that are easy to clean and have exceptional durability. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. A selection of gaskets (for specific applications) and a small benchtop footprint increase the versatility of these ovens. The SHEL LAB economy series of vacuum ovens are outstanding in any application. Features include: Analog Temperature Control Stainless-Steel Interior Built-in Overtemperature Protection 24 Month Limited Warranty

$3,420.84 - $3,742.88

-

Sheldon Manufacturing SHEL LAB FORCED AIR OVEN, 27.6 CUBIC FEET

SHEL LAB - FORCED AIR OVEN, 27.6 CUBIC FEET The SHEL LAB Model SMO28-2 is the largest general-purpose oven on the market. The independent overtemperature safety feature is user adjustable and provides added safety. The turbo blower-assisted forced airflow design coupled with a heavy-duty blower motor offers excellent temperature uniformity and fast recovery times. Airflow is directed evenly across all shelves and samples to ensure consistent drying, curing, and baking results. The SMO large capacity units are perfect for high volume sample and drying applications, including production processes. These units are especially ideal for glassware drying. These SHEL LAB ovens Feature: Three-inch Adjustable Exhaust Port Stainless Steel Shelves Independent Overtemperature Safety High-Temperature Silicone Door Seal No Exposed Heating Elements Added docking collars to intake and exhaust ports to allow ducting to be attached for venting exhaust out of the workspace Shelf standards moved to the sides of the unit for easier shelf installation Wrap Around Insulation Durable Powder Coat Paint Exterior Finish Digital Timer 24 Month Limited Warranty

$13,124.95 $9,854.77

-

Sheldon Manufacturing SHEL LAB FORCED AIR OVEN, 13.8 CUBIC FEET, 230V

SHEL LAB - FORCED AIR OVEN, 13.8 CUBIC FEET, 230V The SHEL LAB SMO14-2 features 14 cubic feet of economical oven space. The independent overtemperature safety feature is user adjustable and provides added safety. The forced, blower-assisted airflow design offers excellent temperature uniformity and fast recovery. A turbo blower and heavy-duty motor combine to direct air over the shelves and samples for even, constant drying, curing, and baking. The large capacity SMO ovens are perfect for high volume sample and drying applications, including production processes. These units are especially ideal for glassware drying. These SHEL LAB Ovens Feature: Three-inch Adjustable Exhaust Port Stainless Steel Shelves Independent Overtemperature Safety High-Temperature Silicone Door Seal Added docking collars to intake and exhaust ports to allow ducting to be attached for venting exhaust out of the workspace Shelf standards moved to the sides of the unit for easier shelf installation No Exposed Heating Wrap Around Insulation Durable Powder Coat Paint Exterior Finish Digital Timer 24 Month Limited Warranty

$9,336.46 $7,740.07

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 5 CUFT

SHEL LAB - OVEN, FORCED AIR, 5 CUFT The SMO5 is equipped with a stainless-steel interior for long-life operation and easy cleaning. With triple wall construction, this oven’s walls minimize external wall temperature which meets CE requirements to keep work spaces cool. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. The SMO5 forced air oven delivers precise uniformity, air distribution, and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45 mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty

$5,653.02 - $5,735.95

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 3 CUFT

SHEL LAB - OVEN, FORCED AIR, 3 CUFT The SMO3 has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit is equipped with a stainless-steel interior for long-life operation and easy cleaning. Its triple wall construction minimizes external wall temperature which meets CE requirements to keep workspaces cool. The SMO3 forced air oven delivers precise uniformity, air distribution, and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty Options: SMO3: OVEN, FORCED AIR, 3 CU FT, 115V SMO3-2: OVEN, FORCED AIR, 3 CU FT, 230V

$4,733.88 - $4,802.99

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 1.5 CUFT

SHEL LAB - OVEN, FORCED AIR, 1.5 CUFT The SMO1 has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit is equipped with a stainless-steel interior for long-life operation and easy cleaning. Its triple wall construction minimizes external wall temperature which meets CE requirements to keep work spaces cool. The SMO1's forced air ovens deliver precise uniformity, air distribution and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45 mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty Options: SMO1: OVEN, FORCED AIR, 1.5 CU FT, 115V SMO1-2: OVEN, FORCED AIR, 1.5 CU FT, 230V

$4,284.68 - $4,388.35

-

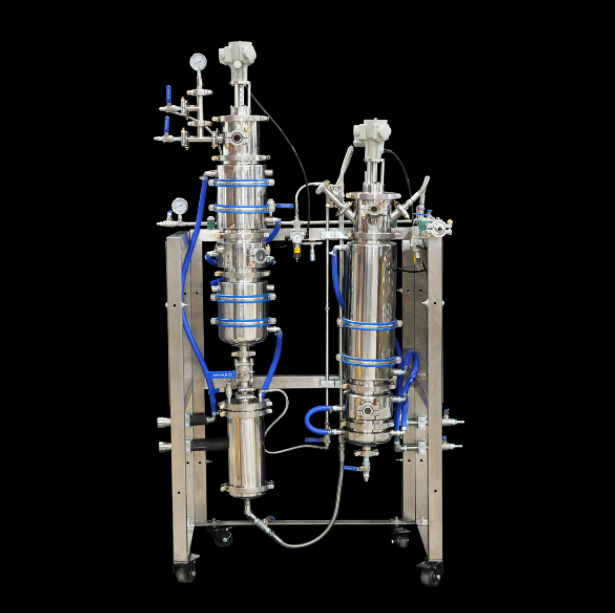

ChemTek ChemTek - Snow Queen Oil Filtration

ChemTek - Snow Queen Oil Filtration Create isolate in minutes Redissolve and reformulate Dual Mixer

$34,553.90

-

ChemTek ChemTek - Magnetic Hot Plate

ChemTek - Magnetic Hot Plate SPECS Hot Plate Area Size: 6” x 6” Power: 110v-550w Display: LCD Display Speed: 100-1600 RPM Temperature Range: RT - 300c

$525.22

-

ChemTek ChemTek - Planetary Centrifuge Vacuum Mixer

ChemTek - Planetary Centrifuge Vacuum Mixer The combination of centrifugal force and vacuum in a planetary vacuum centrifuge mixer allows for the rapid and thorough removal of residual solvents from extracts. The vacuum environment lowers the boiling point of solvents, enabling their efficient evaporation without excessive heat. This is crucial for preserving the integrity and potency of heat-sensitive compounds, such as terpenes, ensuring a purer final product. T-500 Power Supply: 220V Max Speed: 1500 RPM Max Capacity: 2 x 500ml Program: Adjustable program settings for different viscosities Dimensions: L: 29” W: 24” H: 39” Net Weight: 65kg Safety Function: Emergency Stop Button T-1000 Power Supply: 220V upon request Max Speed: 1500 RPM Max Capacity: 2 x 1000ml Program: Adjustable program settings for different viscosities Dimensions: L: 32” W: 29” H: 43” Net Weight: 75kg Safety Function: Emergency Stop Button

$24,878.81 - $34,553.90

-

Fireplace Fuel Clean Burning, Odorless, and Smokeless Grain Ethanol, Fuel for Table Top Fire Pit

Fireplace Fuel Made in USA - From Grain Alcohol Bright Flame fireplace fuel contains two ingredients and were open about sharing our fuel recipe. The mixture is made from grain derived corn based ethanol and there is about 7.8% Isopropyl Alcohol added for enhanced flame ambiance. Ethanol 200 Proof - 87.49% by Wt% (CAS# 64-17-5) Isopropyl Alcohol (IPA) - 7.8% by Wt% (CAS# 67-63-0) Fireplace Fuel Safety Data Sheet (SDS)

$17.95 - $124.38

-

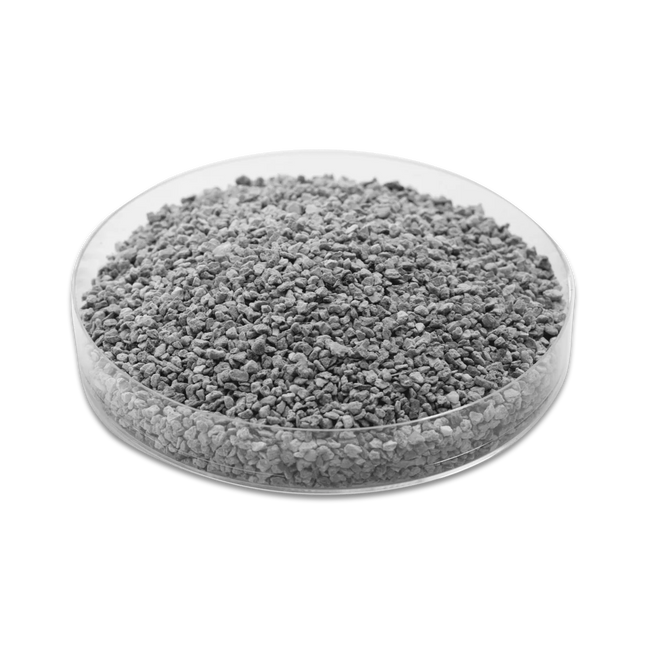

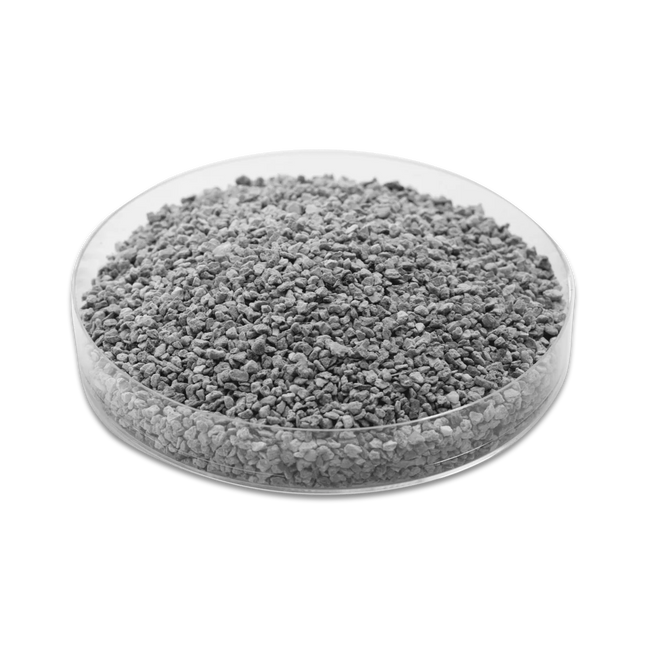

Media Bros Media Bros CRAC Filter Media

COLOR REMEDIATION ACTIVATED CARBON (CRAC) FOR ETHANOL EXTRACTION Our powdered version of the G-CRAC, CRAC, is a highly modified bituminous coal carbon with increased surface area. CRAC is unique because it concentrates reactants via adsorption and then promotes their reaction on the pore's surface, which is best suited for heavy environmental clean-up. PH 7 DESCRIPTION Color Remediation Activated Carbon (CRAC) is a top-shelf carbon powder that has revolutionized extraction. Its high-performance selectivity sets it apart from other filter media and is crucial in producing a high-quality extract free of undesirables and impurities. CRAC stands out due to its meticulous preparation process. Its granular consistency makes it easy to handle and is thoroughly sifted, which minimizes the risk of carbon or dust contamination. This commitment to quality creates a safer, cleaner work environment. CRAC is also environmentally friendly; it's non-toxic, biodegradable, and recyclable. This added layer of safety doesn't compromise its effectiveness; instead, it ensures the integrity of the end product and the health of your workforce. CRAC is pH-neutral double activated, which maximizes the carbon's surface potential, allowing for more efficient adsorption and color remediation. By opting for CRAC, you are choosing a product that has been fine-tuned to deliver the best possible extraction results. CRAC stands out not just for what it contains but also for what it doesn't. CRAC delivers all the microporous, mesoporous, and macroporous media you can handle, providing comprehensive remediation of ethanol extract and oil purity you can count on. At Media Bros, we understand the diverse needs of various operations. Hence, CRAC is available in a 1.5 kg pouch, a 4 kg package, a 10 kg bucket, and a 100 kg drum. Regardless of your operation's size, there is a bag of CRAC tailored to your needs. Wine, cheese, peanut butter, jelly, CRAC, and Activated Alumina. The combination of CRAC and Activated Alumina as a filter bed provides a practical and robust solution for ethanol extraction, creating a superior filter blend that enhances the overall remediation process. NSF Certified Use Media Bros Activated Alumina as an alumina media filter bed for best results. TECHNICAL SPECS Solvent Type Hydrocarbon + Ethanol Color Remediation Level Heavy/High Pesticide Remediation Level High Selectivity/Polarity Level Less Selective/Most Polar Heavy Metal Remediation Yes Moisture Remediation Level Low Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Low Flow pH Level Neutral (pH 7) Best For Older Biomass, Low Quality Suitable for Reruns Yes Distillation Clean-up High Scrub

$103.66 - $5,805.05

-

Media Bros Media Bros G-CRAC Filter Media

GRANULAR COLOR REMEDIATION ACTIVATED CARBON (G-CRAC) FOR EXTRACTION This highly modified granular bituminous coal carbon is specifically engineered to tackle the heaviest environmental contaminants like pesticides, heavy metals, and other environmental factors; G-CRAC is unique in that it concentrates reactants via adsorption and then promotes their reaction on the surface of the pores. PH 7 DESCRIPTION Pssst, bro. If you are looking for a non-toxic, environmentally friendly, highly effective solution to remediate pesticides and heavy metals in biomass, check out G-CRAC. This breakthrough granular activated carbon solution is specifically designed to target and eliminate environmental contaminants in your concentrates and revive your bottom line. The standout feature of G-CRAC is its exceptional ability to remove smoke, pesticides, and heavy metals. It can also reanimate older biomass, giving new life to lower-quality yields. Lost all your profits because of environmental factors outside of your control? No, you didn't — because G-CRAC is here to save the day. Just add G-CRAC to your inline extraction process and let it do its thing. It will absorb those pesky environmental contaminants, leaving you with a product that is free of toxins and safe for consumption. Plus, G-CRAC won't disrupt the flavor or aroma of your extract: like its chunky cousin, CRAC, G-CRAC utilizes a double-activated, pH-neutral, granular blend. This unique feature allows efficient inline processing without compromising terpene retention or processing speed. This product doesn't just meet industry standards - it sets them. With G-CRAC, you can be confident that your concentrates are free from harmful contaminants, ensuring a pure, high-quality end product. Like all of Media Bros' premium filter media, G-CRAC is a food-grade, non-toxic, organic formulation. It is safe to use, environmentally friendly, and will not alter the chemical composition of your concentrates. Packaged in: 1.5 kg pouch, 10 kg bucket, and 100 kg drum NSF Certified TECHNICAL SPECS Solvent Type Hydrocarbon + Ethanol Color Remediation Level Heavy/High Pesticide Remediation Level High Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Low Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate High Flow pH Level Neutral (pH 7) Best For Older Biomass, Low Quality Suitable for Reruns Yes Distillation Clean-up High Scrub

$103.66 - $4,975.76

-

Media Bros Media Bros CR2 Filter Media

CR2 Filter Media Achieving optimal results in supercritical (CO2) extraction requires superior filter media. Enter CR2™ inline filter media. DESCRIPTION Achieving optimal results in supercritical (CO2) extraction requires superior filter media. Enter CR2™ inline filter media. Designed specifically for CO2 extraction, CR2™ is a non-toxic, non-reactive blend of naturally occurring zeolites. Its unique formulation gives it a high adsorption capacity, effectively removing undesirables in CO2 extracts. Like CRX™, CR2™ Filter Media is also designed to handle high flow rates. It exhibits full particle retention even under the demanding high psi conditions present in CO2 extraction. This feature ensures that your CO2 extraction process runs efficiently without compromising the quality of the extract. One common complaint about CO2-extracted products is the so-called "CO2 taste," which can be off-putting for consumers. CR2™ Filter Media tackles this issue head-on, eliminating this bitter taste and ensuring that the final product has greater purity, aesthetic appeal, and consistency. The effect of CR2™ Filter Media on the ‘CO2 taste’ in extracted products can be a game-changer for product quality and consumer satisfaction. All extractors hate baking their filter media or cleaning out caked-on media from their equipment. CR2™ Filter Media does not clog or damage CO2 systems, ensuring smooth operation and longevity of your extraction setup. It was designed by CO2 extraction operators for CO2 operators, so you can focus on extraction rather than worrying about handling issues. Like all of our premium filter media, CR2™ is non-toxic and non-reactive. Nobody should have to wear a HAZMAT suit during CO2 extraction. Using basic safety procedures, our media is organic, natural, and safe to handle. We understand that different operations have different needs, so we provide CR2™ Filter Media in various packages: a 2.5 kg pouch, an 18 kg bucket, and a 200 kg drum. Whether you run a small-scale operation or a large extraction facility, there is a packaging option to suit your needs. FDA GRAS Approved 100% Natural TECHNICAL SPECS Solvent Type CO2 Color Remediation Level Moderately Heavy/High Pesticide Remediation Level Low Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Low Fats/Lipids/Waxes Level Low Crystal Growth Fast Depth Filtration No Flow Rate High Flow pH Level Neutral (pH 7) Best For Slightly Aged Biomass, Medium Quality Suitable for Reruns No Distillation Clean-up Moderate Scrub

$41.46 - $2,764.31

-

Media Bros Media Bros -CRY+ FILTER MEDIA

Media Bros -CRY+ FILTER MEDIA CRY+ is our largest granule size. With a mesh size of 16-x30, this media allows operators to run high-flow processes while maintaining a consistent quality output. DESCRIPTION: CRY+™ Filtration Media: High-Flow, High-Efficiency Filtration CRY+™ is our premium filtration media, designed with a larger granule size (16-30 mesh) to deliver unmatched flow rates without compromising the quality of your extraction. Whether you're processing high volumes or working with challenging biomass, CRY+™ ensures consistent, effective results in every run. Engineered for operators who demand speed and precision, CRY+™ is ideal for high-flow processes where residence time and color remediation are key. With a recommended solvent ratio of 6:1 to 10:1 and the ability to operate at room temperature or below -10°C without clogging, CRY+™ offers flexibility and efficiency for modern extraction setups. Key Features: Larger Granule Size (16-30 mesh): Delivers faster flow rates while maintaining purification performance. Needle Valve Recommended: Fine-tune flow rates for optimal color correction, especially when processing dark or oxidized material. Temperature Resilience: Performs optimally at sub-zero temperatures without clogging. Technical Specs: Use a 4-6” diameter CRC column for best results. Recommended operating pressure: 20-45 psi. Media ratio: 200-300g per 1 lb of biomass. Available Exclusively Through Our Dealer NetworkFind a dealer near you to purchase CRY+™: *A needle valve is recommended on the output (bottom) of the filtration column to properly fine-tune your flow rates. If you are processing dark or oxidized material, a tighter flow restriction will increase residence time, allowing for better color correction. TECHNICAL SPECS Solvent Type Hydrocarbon Color Remediation Level Moderately Heavy/High Pesticide Remediation Level Medium Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Moderate Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate High Flow pH Level Neutral (pH 7) Best For Fresh Frozen, Nugs, High Quality Suitable for Reruns Yes Distillation Clean-up Moderate Scrub SDS

$124.39 - $1,243.94

-

Media Bros Media Bros Medium flow CRX-M

Media Bros Medium flow CRX This non-reactive medium flow variant allows operators to increase operating pressures and surface area for a more fine-tuned process. PH 7 Description: Introducing CRX Medium Flow™ (CRX-M™), a not-quite-powder/fine-grain premium filter media formulated for non-reactive, high flow and high-pressure hydrocarbon extraction. Its texture is designed to replace traditional powdered media like B80 without channeling and clogging issues commonly encountered with conventional powders. Extractors accustomed to traditional powders like B80 will find that CRX-M™ offers similar flow properties but with the added benefit of superior terpene retention. Like all of our premium blends, CRX-M™ is non-reactive, ensuring it's safe and easy to handle in your lab setting. It eliminates the need for extensive clean-up, saving you time and effort. CRX-M™ has all the benefits of its more granular twin, the flagship CRX™. It is a "perfect scrub" media, ideal for high-quality biomass and nug run processing. You want total control over flow and ensure the terpenes and flavonoids are retained from plant to extracted oil. Extraction labs vary in size, and so does our range of filter media. Our CRX-M™ product is available in three convenient packaging options: a 1.5 kg pouch, a 10 kg bucket, and a 100 kg drum. Whether operating on a small scale or running an extensive industrial process, we have the perfect packaging to meet your needs. Technical Specs: Solvent Type Hydrocarbon Color Remediation Level Average/Moderate Pesticide Remediation Level Low Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation No Moisture Remediation Level Low Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Moderate Flow pH Level Neutral (pH 7) Best For Fresh Frozen, Nugs, High Quality Suitable for Reruns No Distillation Clean-up Low Scrub SOP SDS Before you get started, please remember this: As CRX™ and CRY™ are not powders designed not to absorb moisture before use, no baking or preparation is needed. For optimal success, ensure your flow is gentle and consistent. RATIOS Solvent to Biomass: ratios range from 6:1 to 10:1, depending on the quality of the plant matter you are distilling—lower ratios for top-tier biomass and higher ratios for older or lower-quality biomass. Media to Biomass: Load 150 - 250 grams of filter media into filtration housing for every 1 lb of biomass. The media quantity used is dependent on the quality of the biomass. Higher-quality biomass requires less media. Lower-quality biomass requires more media. The lookup table can be used as a reference, but because every kind of plant matter is different, you will need to experiment a little bit to achieve the best results. That said, this chart is an excellent baseline from which to start. TEMPS To ensure optimal performance, keep the temperature at -10°C or below while using the media. Our media is designed to prevent clogging. FLOW When transferring from the biomass vessel to the recovery vessel, maintain a maximum flow rate of 1 GPM. Our media performs best with a consistent and gentle flow. To prevent channeling, avoid sudden hydraulic surges through the CRC column. A shower or initial fill of the column is highly recommended for optimal results. YIELD Any lost yield can be fully recovered by flushing the media with solvent. Most users report achieving substantial yield gains by maintaining high solvent-to-biomass ratios or flushing our media after an extraction transfer.

$41.46 - $2,211.45

-

High Purity Paraffin Lamp Oil - Smokeless, Clean Burning- Kosher - 99.5% Pure

Paraffin Lamp Oil 99.5% Pure - Kosher BVV's 99.5% High Purity Lamp oil is great for indoor and outdoor use. It is a clear, water-white, oily liquid with a low viscosity, and will not thicken with age. Our lamp oil has an extremely low sulfur and nitrogen content. It's a highly refined mineral oil that comes from petroleum and is stripped of its odors. The shelf-life of paraffin lamp oil will last indefinitely if stored in a sealed container. Paraffin oil is a fuel source used to power oil lamps, providing light in a situation where electricity is unavailable, making it a valuable item to stockpile for emergency situations due to its ability to provide light without needing batteries or power. If you're a prepper looking for a fuel source that won't sour with age, we recommended our paraffin lamp oil. BVV® Paraffin Lamp Oil Certificate of Analysis COA BVV® Parafin Lamp Oil Safety Data Sheet

$19.72 - $4,849.99

-

SSP Corporation Tube Stub Adapter

Tube Stub Adapter Duolok Tube Stub Adapter, 3/8 Tube Fitting x 1/2 Tube Stub, 316 SS. Body Material 316 SS Connection 1 - Type Tube Fitting Connection 1 - Size 3/8 in Connection 2 - Type Tube Stub Connection 2 - Size 1/2 in Brand Series Duolok Shape Straight End Connections TF x Tube Stub Production Category 1 Handle Type 0 Handle Color

$41.46

-

Caffeine Powder ≥99.0% USP/FCC/Food Grade

Pure Caffeine Powder USP/FCC/Food Grade - ≥99.0% Pure Our Caffeine Powder has a nice fine consistency. Similar to powdered sugar. It is an anhydrous product so it's free of any water/moisture. Synthetically derived. Caffeine Example COA Certificate of Analysis Chemical Formula: C8H10N4O2 Molecular Weight: 194.19 g/mol CAS Registry Number: 58-8-2 Appearance White Powdery Crystalline Odor: None Density 1.23 g/cm3 @ 20 °C Boiling Point: 178C/352F Solubility in water: Moderately Soluble GHS Pictograms: Irritant GHS Signal Word: Warning GHS Hazard Statements: H302 GHS Precautionary Statements P264, P270, P301+P317, P330, P501 What is Caffeine? Caffeine is a natural stimulant most commonly found in coffee, tea, and certain plants like cacao. It works by stimulating the brain and central nervous system, helping to reduce fatigue and enhance alertness and focus. Chemically classified as a psychoactive drug, caffeine blocks the action of adenosine, a neurotransmitter that promotes relaxation and sleepiness. In addition to its natural sources, caffeine is also added to many soft drinks, energy drinks, and over-the-counter medications. As the world's most widely consumed psychoactive substance, moderate consumption of caffeine has been linked to various health benefits, including improved cognitive function and mood. However, excessive intake can lead to side effects such as insomnia, jitteriness, and increased heart rate. How Much Caffeine is found in coffee, tea, soda, & etc? Coffee drinks Size in oz. (mL) Caffeine (mg) Brewed 8 (237) 96 Brewed, decaf 8 (237) 2 Espresso 1 (30) 64 Espresso, decaf 1 (30) 0 Instant 8 (237) 62 Instant, decaf 8 (237) 2 Teas Size in oz. (mL) Caffeine (mg) Brewed black 8 (237) 47 Brewed black, decaf 8 (237) 2 Brewed green 8 (237) 28 Ready-to-drink, bottled 8 (237) 19 Sodas Size in oz. (mL) Caffeine (mg) Citrus (most brands) 8 (237) 0 Cola 8 (237) 22 Root beer (most brands) 8 (237) 0 Energy drinks Size in oz. (mL) Caffeine (mg) Energy drink 8 (237) 71.9 Energy shot 2 (60) 215 How Much Caffeine should I take? The recommended dosage of caffeine varies based on individual tolerance, age, and health factors. For most healthy adults, a moderate daily intake of 100-200 mg of caffeine is considered safe. This equates to about 1-2 cups of brewed coffee or 2-3 cups of tea. Consuming caffeine in moderate amounts can enhance alertness, boost mood, and improve focus. However, exceeding 200 mg per day may lead to side effects like restlessness, insomnia, rapid heart rate, and headaches. For sensitive individuals or those with certain health conditions, even lower doses can cause adverse effects. It’s important to monitor caffeine intake from all sources, including coffee, tea, energy drinks, and supplements, to ensure safe consumption levels.

$23.50 - $1,243.94

-

Mastercool Mastercool Blue 60" HVAC Hose

This HVAC hose will fit 1/4" SAE or JIC fittings. One end of the hose has a fitting made to depress a Schrader valve within the male fitting, the other end of the hose is a standard connection.

$24.88

-

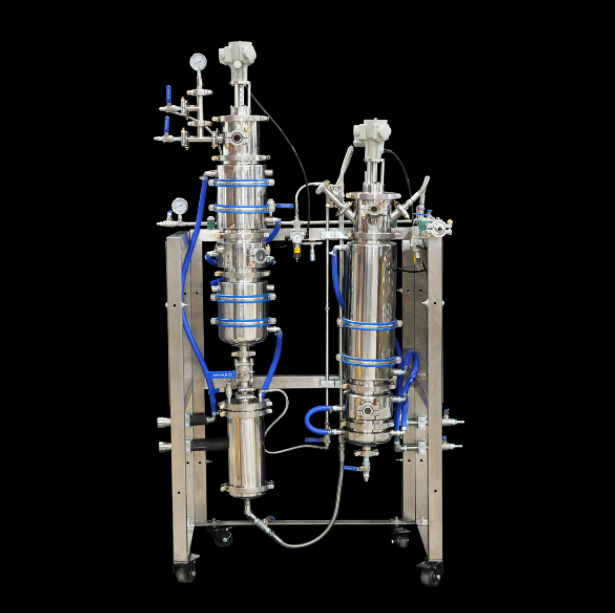

10LB+ EVO Certified Closed Loop Extractor

10LB+ EVO Certified Closed Loop Extractor The 10LB+ EVO Certified Closed Loop Extractor builds upon the proven success of the 5LB EVO, pushing the boundaries of performance, capacity, and innovation. Tailored for extractors scaling up their operations, this system retains the advanced features of its predecessor while offering increased throughput and operational efficiency to meet the demands of larger-scale production. With a rugged design suited for both cured and fresh frozen materials, the 10LB+ EVO supports low-temperature extractions and rapid solvent recovery, leveraging 1.5" full-bore recovery lines to reduce cycle times without compromising on extract quality, safety, or ease of operation. Optimized for a 10-pound extraction process at a 5:1 butane-to-biomass ratio, the system includes dual 55LB jacketed and baffled solvent collection/recovery tanks and an additional jacketed material column for pre-packing. This feature enhances efficiency and ensures seamless processing. With 3X 6"x36" jacketed material columns, each equipped with individual inline CRCs (Color Remediation Columns), the 10LB+ EVO guarantees maximum extraction efficiency, exceptional extract purity, terpene preservation, and unmatched filtration flow rates. Engineered for compliance and reliability, the 10LB+ EVO is peer-reviewed and 3P-certified to meet or exceed Class 1 Division 1, NFPA 58, and ASME standards, incorporating 3A sanitary compression and Tri-Clamp fittings for durability and precision. Capable of processing 80+ pounds of biomass per 8-hour shift, this system delivers the scalability, precision, and affordability extractors need to elevate their production capabilities. Key Features 1.5" Full-Bore Recovery LineAccelerate recovery with oversized 1.5” lines, minimizing cycle times and boosting throughput. Inline and Independent Adsorbent Filtration ColumnsEnsure pristine extract clarity and unadulterated terpene profiles with individual inline CRCs for each material column. Optimized for maximum flow rates and minimal retention time to preserve flavor. Independent Solvent InjectionReduce downtime and streamline operations with independant solvent injection for smooth transitions and increased efficiency. Additional Standby Material ColumnIncrease throughput with an extra pre-packed material column, ready to swap in for non-stop processing. Sanitary Compression and Tri-Clamp FittingsBuilt for reliability, the system’s sanitary compression and Tri-Clamp fittings ensure leak-proof assembly and simplified maintenance. Processing Power Capacity Per Batch: 10LB Cycle Time: 30-45 Minutes* Capacity: 80+lb, per 8-hour shift* Extracts: isolate/sauce, distillate, vape pens, shatter, and wax/sugar *Cycle Time & Capacity vary based on heater and chiller pairing* Specifications 3X 6"x36" 5LB Material Column 3X 6"x6" Adsorbent Filtration Column 3X 1-5um Dutch Weave Sintered disk filter stacks 1.5"X 48" Braided Inline molecular sieve recovery line 10X 1.5" Certified Borosilicate Sight Glasses 5X 250 PSI ASME Safety Valves 5X -30hg-250PSI Compound Pressure Gauges 1.5" Full Bore Recovery Lines 1/2" Compression process Flow lines Footprint (DxWxH) 30"x68"x79" Weight: 650 lb Maximum Pressure Rating: 250PSI Compliance Class 1, Division 1 compliant Designed to ASME standards NFPA 58 LPG compliant 3P Certified

$31,789.59

-

24" & 36" Filter Paper (Qualitative, Large Diameter)

Ashless Filter Papers - Qualitative Ashless quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Low ashless content: <0.1% Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Qualitative Sizes Available: BIO-1 11um - Medium BIO-4 20um - Fast BIO-5 2.5um - Slow BIO-6 3um - Slow Ash Content <0.1% Quantity per Pack 100 Diameter 24 - 36" Technical Data: Grade Particle Retention Appearance Speed Ash Content (%) Basis Weight (g/m2) Wet burst (mm H2O) BIO-1 11um Smooth Medium <0.1 80.0±4.0 >140 BIO-2 8um Smooth Medium <0.1 80.0±4.0 >140 BIO-4 20um Smooth Fast <0.1 80.0±4.0 >120 BIO-5 2.5um Smooth Slow <0.1 80.0±4.0 >180 BIO-6 3um Smooth Slow <0.1 80.0±4.0 >180 BIO-40 8um Smooth Medium <0.007 80.0±4.0 >140 BIO-41 20-25um Smooth Fast <0.007 80.0±4.0 >120 BIO-42 2.5um Smooth Slow <0.007 80.0±4.0 >180 BIO-43 16um Smooth Medium to Fast <0.007 80.0±4.0 >120 BIO-44 3um Smooth Slow <0.007 80.0±4.0 >180

$276.43 - $967.51

-

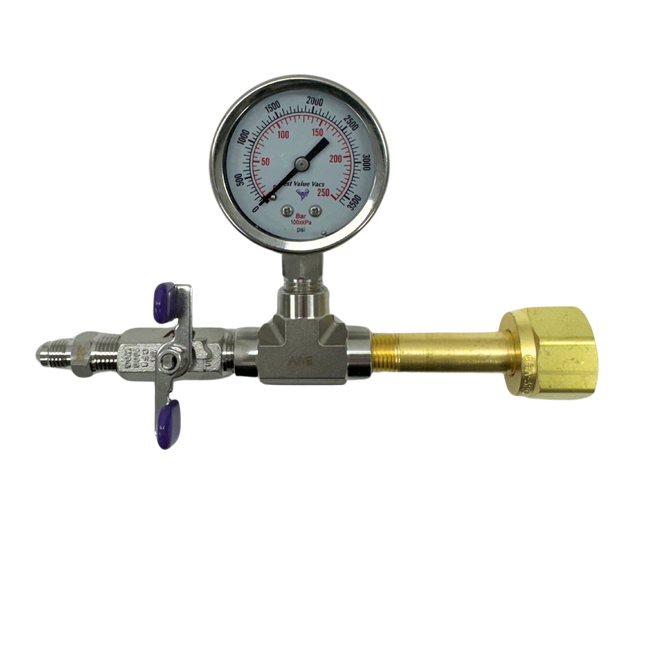

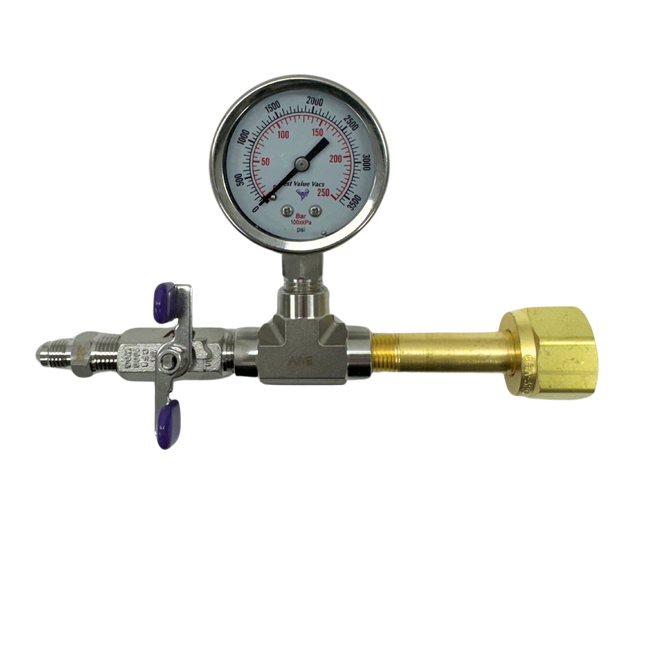

CGA 320 CO2 Tank Regulator

This tank regulator will control the rate of fluid or gas flow using a butterfly valve. Our BVV butterfly valve is rated to 1000 psi, and is made of 304 stainless steel and features a PTFE valve seat making it compatible with CO2. The output will connect to a 1/2" JIC flare hose (seen here BVV JIC 1/4" Hose).

$172.77

-

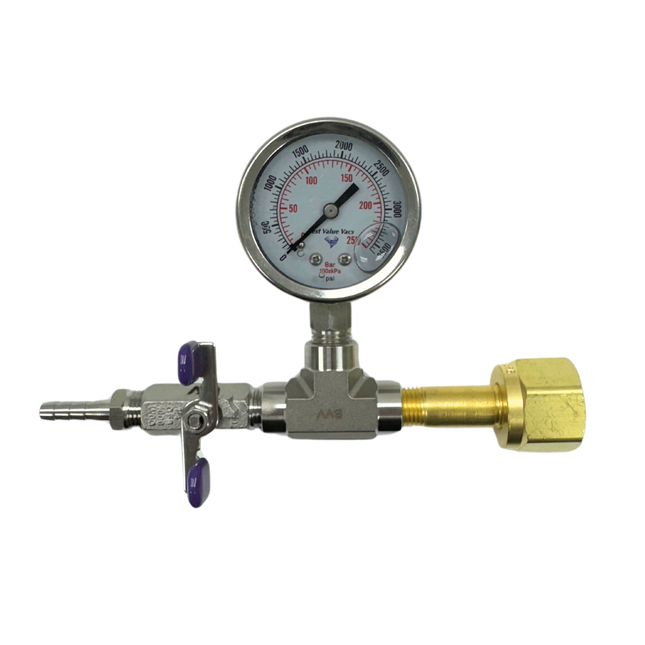

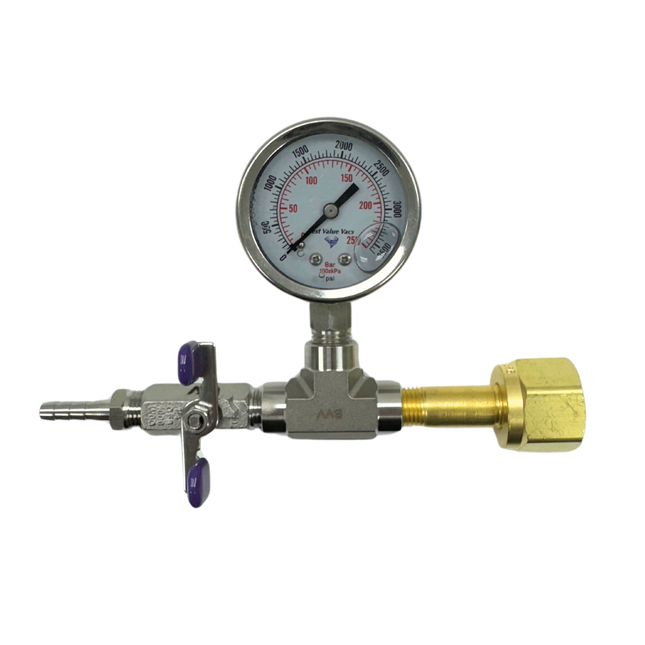

CGA 326 Nitrous Oxide Tank Regulator

This tank regulator will control the rate of fluid or gas flow using a butterfly valve. Our BVV butterfly valve is rated to 1000 psi, and is made of 304 stainless steel and features a PTFE valve seat making it compatible with N2O. The output will connect to a 1/4" barb for tubing. (seen here BVV 1/4" Tubing).

$193.50

-

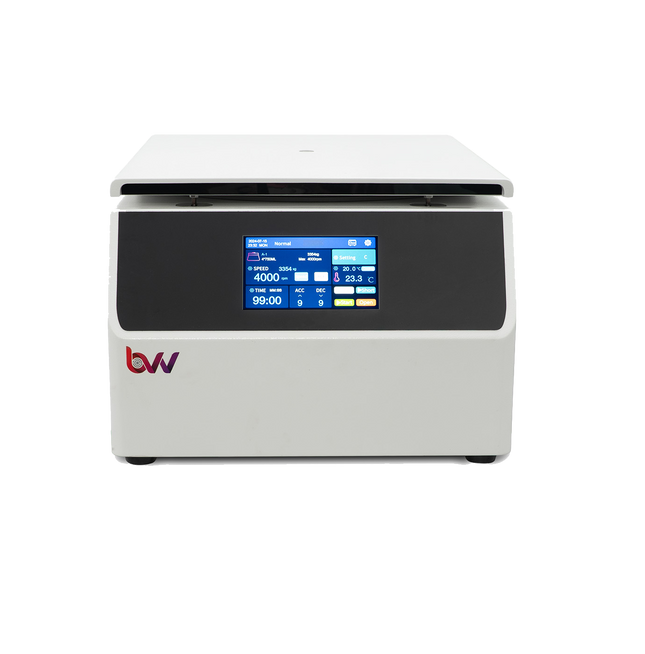

Centrifuge C250

BVV C250 Centrifuge The BVV C250 Centrifuge is a large-capacity desktop centrifuge with broad functionality suitable for various applications. The BVV C250 Centrifuge can be used to separate or concentrate samples by density or utilized to separate solid constituents from liquid constituents. The BVV C250 Centrifuge has a maximum speed of 5000rpm with a maximum centrifugal force is 3899xg which allows for fast separation times. It's user friendly simple to use touch screen interface allows for easy operation even when wearing gloves. With built-in cooling fans, the BVV C250 ensures sample preservation while allowing for heat-assisted separations. While the BVV C250 is not actively heated or refrigerated it typically operates at 130F/54C allowing for quick and efficient separations. For Solid & liquid separations we recommend utilizing our 45 Micron Large Rosin Bags, The BVV C250 comes with 3 sets of centrifuge baskets including: 4X 250ML Stainless Steel Separators 4X 2X 50ML Centrifuge Tube Plastic Inserts (8X 50ML Centrifuge Tube Capacity) *Centrifuge tubes not included* 10X Small Rosin Bags 45 Micron Features •Digital LCD display with a user-friendly interface for easy operation. •Microprocessor control, DC brushless motor with low noise and high accuracy. •Dual locking design with lock alarm on the interface. •Centrifuge chamber is made of 304 stainless steel to avoid corrosion. •Can switch RPM/RCF during operation. •Store up to 10 preset programs •Sound and indicator alarm for defaults. •Protection including door closing, malfunction, over-speed, over-heating, imbalance,etc. •Speed is adjustable to avoid sample suspension to ensure the performance. Technical Specifications Model BVVC250 Max Capacity 4*250mL Max Speed 5000rpm Max RCF 3899Xg Speed Accuracy ±10r/min Time Setting 0-99min59s Soft Brake 9 Ramps Noise ≤65dB(A) Power Supply 110V 60HZ Power Consumption 500W Net Weight 66lb/30kg Packing Size 20"x14"x*11"

$4,561.11

-

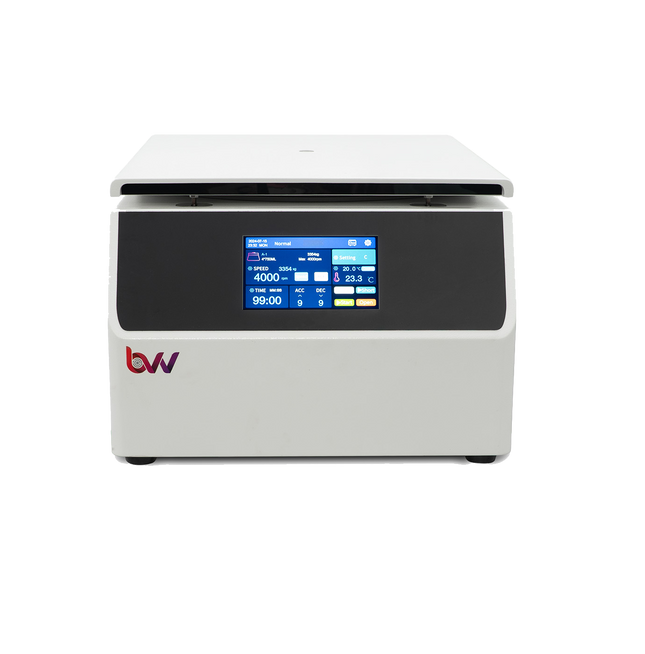

Centrifuge C750

BVV C750 Centrifuge The BVV C750 Centrifuge is a large-capacity desktop centrifuge with broad functionality suitable for various applications. The BVV C750 Centrifuge can be used to separate or concentrate samples by density or utilized to separate solid constituents from liquid constituents. The BVV C750 Centrifuge has a maximum speed of 4000rpm with a maximum centrifugal force is 3354xg which allows for fast separation times. It's user friendly simple to use touch screen interface allows for easy operation even when wearing gloves. With built-in cooling fans, the BVV C750 ensures sample preservation while allowing for heat-assisted separations. While the BVV C750 is not actively heated or refrigerated it typically operates at 130F/54C allowing for quick and efficient separations. For Solid & liquid separations we recommend utilizing our 25 Micron Large Rosin Bags, The BVV C750 comes with 3 sets of centrifuge baskets including: 4X 750ML Stainless Steel Separators (300 Gram Capacity 1,200 Grams Total) 4X 5X 50ML Centrifuge Tube Plastic Inserts (20X 50ML Centrifuge Tube Capacity) *Centrifuge tubes not included* 4X 750ML Polypropylene Bottles 10X Large Rosin Bags 25 Micron Features •Digital LCD display with a user-friendly interface for easy operation. •Microprocessor control, DC brushless motor with low noise and high accuracy. •Dual locking design with lock alarm on the interface. •Centrifuge chamber is made of 304 stainless steel to avoid corrosion. •Can switch RPM/RCF during operation. •Store up to 10 preset programs •Sound and indicator alarm for defaults. •Protection including door closing, malfunction, over-speed, over-heating, imbalance, etc. •Speed is adjustable to avoid sample suspension to ensure the performance. Technical Specifications Model BVVC750 Max Capacity 4*750mL Max Speed 4000rpm Max RCF 3354Xg Speed Accuracy ±10r/min Time Setting 0-99min59s Soft Brake 9 Ramps Noise ≤65dB(A) Power Supply 110V 60HZ Power Consumption 1000W Net Weight 114lb/52kg Dimensions 24"x19"x14"

$7,325.43

-

KF-40 Stainless Steel Ball Valve (Nitrogen Tested)

KF-40 (NW40) Stainless Steel Ball Valve This ball valve has a KF40 (NW40) High Vacuum Flange to adapt to any other KF40 pump or manifold if needed and is made out of 304 stainless steel with a PTFE seat and seals. BVV™ Tri Clamp Ball Valve - Data Sheet

$207.32

-

Synder NFG Membrane (600-800Da MWCO)

Synder NFG Membrane With a pore size ranging between 0.1-10nm,Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 600-800 DA Typical Operating Flux 55-60 GFD Average Lactose Rejection: 60% Average MgSO4 Rejection: 50% Average NaCl Rejection: 10% Maximum Operating Pessure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 4-9 Ambient Temperature Operating pH Range: 4-10 Maximum Temperature Cleaning pH Range: 3-10 Ambient Temperature Cleaning pH Range: 3-10.5

$798.20 - $1,765.70

-

50% Hydrogen Peroxide Tech Grade NSF, H2O2

50% Technical Grade Hydrogen Peroxide Our Technical-grade 50% peroxide tests at ~50.4%. Is the strongest proxied we offer, next to our 35% Technical Peroxide, Our Technical Grade 50% hydrogen peroxide is formulated with a special stabilizer (organophosphonate) package that replaces transition metals stabilizers typically found in hydrogen peroxide solutions. Our Peroxide is NSF® Certified. NSF-certified means a product was independently verified for safety, sanitation, and quality by NSF. NSF certification is recognized by health departments, government agencies, and industry associations. *Certified under ANSI/NSF Standard 60 Drinking Water Additives-Health Effects. Dosage levels shall be in accordance with NSF requirements. 55 Gallon Drum weights 548lbs, 270 Gallon Tote weighs 2500lbs. hydrogen peroxide usually loses less than 1% of its initial concentration in one year (0.5% for a 50% solution). 50% Hydrogen Peroxide NSF Technical Grade Certificate of Analysis 50% Hydrogen Peroxide NSF Technical Grade Safety Data Sheet Chemical Formula: H2O2 Molecular Weight: 34.015 g/mol CAS Registry Number: 7722-84-1 Appearance Colorless Liquid Odor: None Density 1.196 g/cm3 @ 20 °C (68 °F) Boiling Point: 114 °C (237 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H302 + H332, H314, H335 GHS Precautionary Statements P210, P220, P260, P261, P264, P270, P271, P280, P283, P301+P317, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P306+P360, P316, P317, P321, P330, P363, P370+P378, P371+P380+P375, P405, P420, and P501 UN Identification Number: 2014 Proper Shipping Name: 50% Hydrogen Peroxide, Aqueous Solution Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard:

$359.36 - $829.29

-

12" Hemispherical Extractor Lid with 6" Triclamp Center

12" Hemispherical Extractor Lid with 6" Triclamp Center This End Cap comes with Four FNPT Threaded connections, two 2" Tri-Clamp ferrules welded to the end cap, and a 6" Tri-Clamp center port. They allow the user to adapt and connect threaded connections to the NPT ports and Tri-Clamp lid connections to the others. These 7 connections are welded on a 12" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 2" Tri-Clamp (2x) 6" Center Tri-Clamp Port 12" Tri-Clamp 1/4" - 18 FNPT (x2) 1/2" - 14 FNPT (x2) Standard: 3A

$483.75

-

1/2" Fractional Tube Fitting Hose

1/2" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/2" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 5 1/2"

$103.66 - $179.68

-

3/8" Fractional Tube Fitting Hose

3/8" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 3/8" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 4"

$81.55 - $165.86

-

Dipropylene Glycol (DPG) Low Odor

Dipropylene Glycol (DPG) - Low Odor - Technical Grade Dow® Chemical Product Dipropylene glycol (DPG) is a clear, colorless, and odorless liquid that is commonly used as a solvent, humectant, and emulsifier in a wide range of industries. It is a derivative of propylene glycol and consists of two propylene glycol molecules connected by an ether bond. Dipropylene glycol is less hygroscopic than propylene glycol and has a higher molecular weight, which makes it more viscous and less likely to evaporate quickly. In the fragrance and cosmetic industries, DPG is often used as a carrier for essential oils, perfumes, and other aromatic compounds, helping to dissolve and evenly distribute them in formulations. It helps improve the texture of creams, lotions, and other personal care products, while also enhancing their stability and shelf life. Due to its low toxicity, DPG is considered safe for use in food and cosmetic products in regulated amounts. However, as with many chemicals, prolonged or excessive exposure may lead to skin irritation or sensitivity in some individuals. As defined by OSHA Hazard Communication Standard, this product is not known to be a hazardous chemical. Applications and Uses for DPG: Fragrance and Perfume Industry: DPG is commonly used as a carrier or solvent for essential oils and fragrance compounds. It helps to dilute and stabilize fragrances, making them easier to apply and ensuring that the scent lasts longer. Cosmetics and Personal Care Products: DPG is a key ingredient in many personal care products such as lotions, creams, shampoos, deodorants, and soaps. It acts as a humectant (moisture-retaining agent), solvent, and emulsifier, helping to improve the texture, stability, and overall effectiveness of the product. Fog Solution: dipropylene glycol is frequently found in fog juice / liquid, where it works as a base to create heavy low hanging fog vapor. Where as propylene glycol produces a lifting lighter fog vapor that tends to go towards the ceiling. Our low odor formula make it perfect for indoor fog applications. Pharmaceuticals: In the pharmaceutical industry, dipropylene glycol is used as a solvent in medications, especially in liquid formulations like oral solutions, syrups, and injectable drugs. It helps dissolve active ingredients and stabilize the formula. Industrial Applications: DPG is used in the manufacture of paints, coatings, cleaning agents, and lubricants. It functions as a solvent and helps improve the consistency and spreadability of these products. Antifreeze and De-icing Products: While less common than propylene glycol, dipropylene glycol can also be used in some antifreeze and de-icing formulations due to its low freezing point and excellent solvency properties. Food and Beverages: Though not as widely used as propylene glycol, DPG can be found in certain food and beverage products, where it serves as a solvent or stabilizer for flavorings, colorants, and other additives. Textile and Leather Industry: DPG is used as a softener and finishing agent for textiles and leather products, contributing to a smooth texture and enhancing the durability and quality of the materials. What are some of the fragrance products you can make with diproplene glycol (DPG)? Perfumes and colognes Skin care products (creams, lotions, body oils, sun-care products) Deodorants and antiperspirants (roll-on, stick deodorants) Hair care products (shampoos, conditioners, styling, coloring products) Shaving products (creams, foams, gels, after-shave lotions) Bath and shower products Dipropylene Glycol Certificate of Analysis COA Dipropylene Glycol Safety Data Sheet SDS

$24.88 - $1,923.96

-

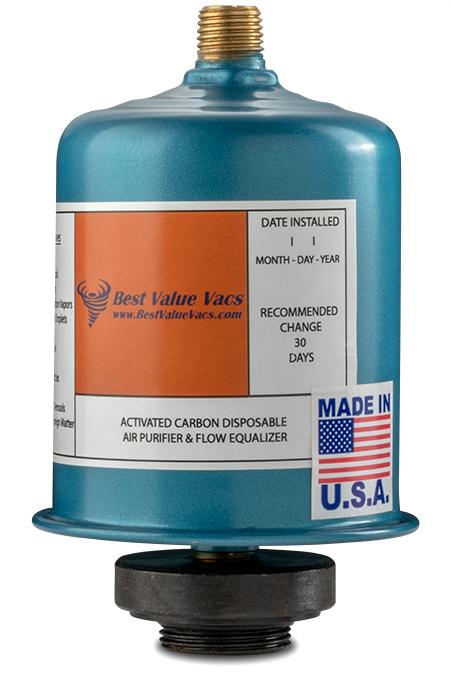

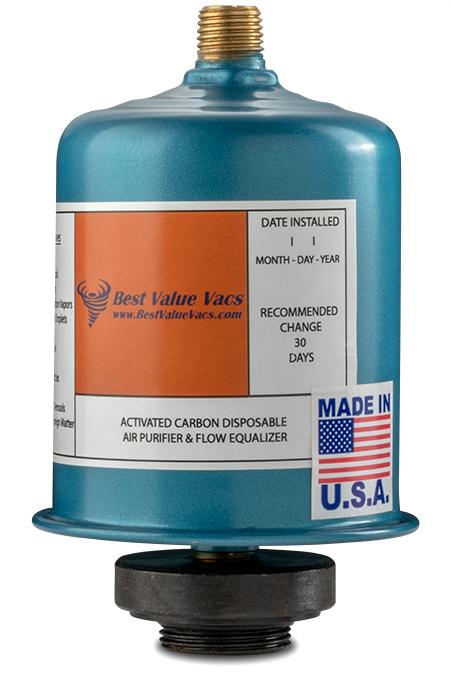

Purple BVV Vacuum Pump Activated Carbon Exhaust Filter

Carbon Exhaust Filter for BVV Vacuum Pumps Replaces Koby Junior (US Patent# 3169112A) BVV Vacuum Pump Activated Carbon Filter for use with Purple BVV vacuum pumps. Pump Models Include: BVV4D, BVVSF6S, BVVSF6D, BVV7S, BVV9D, BVVSF12D This filter will adsorb contaminants such as oil aerosols, oil vapors, certain other hydrocarbon vapors, and trace moisture. They also trap all foreign solid particles and bacteria down to 0.5 microns in size. Key Features: Purifies Exhaust Gases from Vacuum Pumps Up to 19 CFM 0.5 Micron Filtration levels. Helps Maintain Safe Working Environment Adsorbs Organic Vapors and Small Particles High-Efficiency Filtration Minimal Pressure Drop Maintenance Free - Completely Disposable Pressure Safe to 90 PSI M30 x 1.0 - Brass Pump Connection Filter connections 1/4" NPT Pipe Fitting Connections Removes the following contaminants: Oil Mist Oil Aerosols Oil Vapors Hydrocarbon Vapors Moisture Droplets Dust Pipe Scale Rust Fine Particles Odors Organic Aerosols Other Foreign Matter Lifespan:720 hrs. of continuous operation. (Then replacement is recommended) **NOTE PUMP NOT INCLUDED

$145.13

-

Scratch and Dent 20LB 99.5% High Purity Gas Tanks

Disclaimer: Tanks are discolored, scratched or dented on some portions of the tank, but is still operable and safe to use. The 99.5% high purity gas inside is unaffected by the exterior blemishes. (Note: Website pictures of tanks are not the actual representation/condition of the tank you may be sent.) DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. BVV™ always recommends distillation of every solvent before use. Tank contains no dip tube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale ***Shipping Notes: Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer wants to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers.

$366.27 $310.99

-

1/2" Compression End Cap 1.5" Triclamp

1/2" BVV Compression End Caps These End Caps come with a 1/2" Female Compression connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a 1/2" male tube stub connection to the lid. Specifications Material 304 Stainless Steel Connection Type: Tri-Clamp 1/2" Female Compression Connection Standard: 3A

$85.69

-

Ethanol 200 Proof, SDA 40B (100% ABV) Lab Grade

Ethanol 200 Proof, SDA 40B 100% AVB (alcohol by volume) HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL Specially denatured alcohol formula 40B, contains trace amounts (less than 0.125% combined) of the denaturants tert-butyl alcohol and denatonium benzoate, compliant with United States Title 27 of the Code of Federal Regulations, Section 21.151. SDA-40B denatured ethanol is a popular choice for cosmetic applications because studies have shown low toxicity in topical applications. It is very popular in perfumes and colognes, earning the nickname of perfumer's alcohol. It is also often used as the alcohol component to hand sanitizers. The high solvency power of SDA 40B 200 proof lends to ideal use in the production of inks, adhesives and coatings. The term "200 proof" refers to the alcohol's strength, which is equivalent to 100% alcohol by volume (ABV). This means that there is no water, or other substances present in the alcohol, making it very pure and highly concentrated. Chemical Formula: CH3CH2OH Molecular Weight: 46.07 CAS Registry Number: 64-17-5 Appearance Colorless Liquid Odor: Sweet, alcohol-like Density 0.789 g/cm3@ 20 °C (68 °F) Boiling Point: 78.5 °C (173.3 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319, H335, H336 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P370+P378, P403+P235, and P501 UN Identification Number: 1170 Proper Shipping Name: Ethanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Ethanol 200 Proof, SDA 40B Certificate of Analysis (COA) Ethanol 200 Proof, SDA 40B Safety Data Sheet (SDS)

$34.55 - $4,353.79

-

Vegetable Glycerin VG 99% Food Grade

Vegetable Glycerin BVV vegetable glycerin is plant-based for use in foods, cosmetics, and skin use. Its USP / NF which means it meets the highest quality standards and makes it suitable for any use. Our propylene glycol is primarily derived from soybeans and canola. Soybean or canola seeds are processed through a crushing, dehulling, conditioning, flaking and extraction operation into a crude vegetable oil. This vegetable oil is further processed into refined oil. The refined oil is then transformed through a transesterification process into crude biodiesel and crude glycerin. The crude glycerin is further processed through several evaporation and distillation steps into a refined, kosher USP-specification-grade Glycerin. What is glycerin? Also known as glycerol, vegetable glycerin, common sources include triglyceride-rich vegetable fats, such as soy, coconut, and palm oils. Most vegetable glycerin comes as a byproduct of industrial chemical reactions. For example, vegetable oils can either undergo a process known as saponification. or transesterification to produce vegetable glycerin. These are common steps in the soap and biodiesel manufacturing processes. They involve heating the oils under pressure or together with either an alkaline or alcohol solution. This process causes glycerin to split away from the fatty acids. Manufacturers can then extract the odorless, sweet tasting, syrup-like liquid known as glycerin. Vegetable Glycerin VG 99.7% Pure Food Grade USP Certificate of Analysis COA

$24.88 - $4,008.25

-

Ethylene Glycol 99.9% Lab Grade

Ethylene Glycol 99.9%, also know as the trade name Mono-ethylene Glycol (MEG). Ethylene glycol (EG) is by far the most produced glycol product. This glycol is polyester grade which means its the highest purity 99.9% and is therefore the highest grade available. There are 3 grades available: : fibre, industrial and antifreeze. The markets for EG products are polyester fibres, polyethylene terephthalate (PET) plastics, coolants in automobile antifreeze, and resins. The excellent humectant (hygroscopicity) properties of EG products also make them ideal for use in fibres treatment, paper, adhesives, printing inks, leather and cellophane. Ethylene glycol is also a commonly used with fog generators or artificial smoke production. Ethylene Glycol Certificate of Analysis COA Ethylene Glycol Safety Data Sheet SDS

$24.88 - $3,870.04

-

CDA 12A w/ Toluene High Purity Extraction Solvent