Meta Purification

-

2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head

2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head This unit carries a 2-day lead time The 2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head is a great setup for smaller scale processors that want a budget friendly system without sacrificing quality on the main components that make a short path great. We understand that as an operator our customers want to be able to start their system and operate in ideal conditions run after run. That is why we paired a full-bore setup with a 14.1CFM pump that will assure the lowest vacuum depth will be pulled every time. Main components such as the distillation head, vacuum valve adapter, and cold trap are all American blown glass. These components allow us to present this system that will repeat in performance time after time. For a in depth analysis of this system please view the following videos. Here you will see the system setup, component explanation, and even see it perform in a first and second distillation pass. These runs were all performed in our lab and the data was used to help fine tune the system. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Video 1 - Setup and Component Explanation Video 2 - Setup Addendum Video 3 - Fist pass Distillation Video 4 - Second Pass Distillation The 2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head Includes: 1 First Pass Distillation Operating Procedure 1 P2 Distillation Kit 1 2L Double Neck Boiling Flask 1 Full Bore Vacuum Valve Adapter 1 BVV MP7H Heater 1 2L Heating Mantle 1 Ribbed Glass Cold Trap 1 Bullseye Precision Vacuum Gauge 1 BVV Pro Series 14.1CFM Rotary Vane Pump (Comes filled with oil. Recommend purchasing additional Ultra 19 Vacuum Pump Oil. SKU: INLAND19-ULTRS-1G) 1 Oil Mist Filter Trap for Rotary Vane Pump 1 24/40 250ml Single Neck Round Bottom Flask 3 24/40 500ml Single Neck Round Bottom Flask 1 24/40 Glass Funnel 1 Vacuum Manifold for Rotary Vane Pump 1 1 Meter Bellow Hose 1 PTFE Magnetic Stirring Bar Retriever 1 24/40 Metal Keck Clip 6 24/40 Plastic Keck Clips 3 250-500ml Cork Stands 2 Chain Clamps 1 Boss Head with 3 Finger Clamp 1 BVV Lab Stand 10 Fiber Glass Insulation Rope 1 Dow Corning High Vacuum Grease 1 10/30 Non-Mercury Glass Thermometers 1 24/40 – 10/30 Glass Adapter Bushing 1 24/40 – 1/8” Thermometer Adapter 1 24/40 Straight Adapter 2 6”x6” Scissor Jack 3 36” Threaded Lab Stand Rod 2 Gl14 – 8mm Barb 6 ¼” Silicone Tubing 2 PTFE Magnetic Stirring Bar 4 Hose Clamp with Butterfly Key ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,919.03

-

Large 1-Micron Refinement Filter

Large 1-Micron Refinement Filter Filter large volumes of solutions with ease with our Large 1-micron Refinement filter. complete with our 1-micron Dutch Weave sintered disk these refinement filters provide complete retention of the filter paper making it impossible for suspended particles to bypass the filter paper. Made from the highest quality 304 stainless steel parts this large refinement filter is built to last making it a great alternative to polypropylene filter trolleys. Our Large 1-Micron Refinement filter is available as a complete kit with and without the a Welch BTpro100 Diaphragm Pump. Processing Power Funnel Capacity: 22.24 Liters/5.88 Gallons Collection Capacity: 50 Liters/13.2 Gallons Specifications 12"x12" Funnel Body 12" 1um Dutch Weave Sintered Disk 12" Hemispherical Ring stand 1/2" JIC Drain Valve 50L Stainless Steel Carboy Collection base -30Hg Vacuum Gauge 1/2" JIC Vacuum Port 3/8" JIC Diptube Valve 1/4" JIC Butterfly Accessory Valve 350MM Ashless Filter Paper Silicone Gaskets

$4,008.25 - $9,398.66

-

ChemTek ChemTek Wide Mouth Basket Support - Large

ChemTek Wide Mouth Basket Support Support for the stainless micron mesh baskets.

$138.22 - $483.75

-

ChemTek ChemTek Regular Mouth Stainless Jar

ChemTek Regular Mouth Stainless Jar Our stainless jar is designed to be used in ChemTek centrifuges to hold the basket and support it during centrifugation. The cup catches all the liquids from the spinning process. It is vacuum insulated and triple-walled for reinforcement. Specifications: Material: 304 Stainless Steel 12oz

$37.32

-

ChemTek ChemTek - Planetary Centrifuge Vacuum Mixer

ChemTek - Planetary Centrifuge Vacuum Mixer The combination of centrifugal force and vacuum in a planetary vacuum centrifuge mixer allows for the rapid and thorough removal of residual solvents from extracts. The vacuum environment lowers the boiling point of solvents, enabling their efficient evaporation without excessive heat. This is crucial for preserving the integrity and potency of heat-sensitive compounds, such as terpenes, ensuring a purer final product. T-500 Power Supply: 220V Max Speed: 1500 RPM Max Capacity: 2 x 500ml Program: Adjustable program settings for different viscosities Dimensions: L: 29” W: 24” H: 39” Net Weight: 65kg Safety Function: Emergency Stop Button T-1000 Power Supply: 220V upon request Max Speed: 1500 RPM Max Capacity: 2 x 1000ml Program: Adjustable program settings for different viscosities Dimensions: L: 32” W: 29” H: 43” Net Weight: 75kg Safety Function: Emergency Stop Button

$24,878.81 - $34,553.90

-

ChemTek ChemTek L550 Centrifuge

ChemTek L550 Centrifuge L550 centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Specifications: Power Supply:110V 50/60Hz Max Speed:4000 RPM Max RCF:3040xg Max Capacity:4x500ml Time Setting Range:1min - 99min Speed Accuracy:± 10r/min Noise: ≤65dB Power Consumption:750W Net Weight:115lbs Comes with: (16) 50ml Tube (4) Regular Mouth Basket (4) Regular Mouth Stainless Jar Lid/Band (4) Four 50ml Tube Holder Insert (4) Regular Mouth Jar Spacer Insert (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves ChemTek L550 Centrifuge User Manual ChemTek L550 Centrifuge SDS

$6,496.13

-

ChemTek ChemTek L500 Centrifuge

ChemTek L500 Centrifuge The L500 Benchtop Centrifuge is our introductory model designed to have a very compact footprint to fit on every lab bench. Specifications: Power Supply:110V 50/60Hz Max Speed:4200 RPM Max Capacity:4x50ml Time Setting Range:1min - 99min Speed Accuracy:± 30r/min Noise:≤65dB Power Consumption:250W Net Weight:42lbs Comes with: (16) 50ml Tube (1) 100pack 25 Micron Centrifuge Bags (2.5”x4”) (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves ChemTeck L500 Centrifuge User Manual ChemTeck L500 Centrifuge SDS

$2,487.88

-

Neocision 5L Neocision Short Path Distillation Kit

5L Neocision Short Path Distillation Kit This unit carries a 2 day lead time. The 5L Neocision Short Path Distillation Kit features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. The Premium Turnkey Kit Includes: 5L Neocision Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$9,605.98

-

2L Standard Short Path Parts Kit

Short Path Distillation Setup Short path distillation is used for compounds that are not stable at high temperatures. It can also be used to purify small amounts of a compound. The 2L Distillation Kit gives users an easy to use system that will get them up and running at an affordable price. It includes all stands, clamps, clips, This Kit Does NOT include a vacuum pump, circulator, or heating source. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Standard Distillation Turnkey Setup which includes vacuum pump, circulator, and mantle. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Heating Mantle: BVV 2L Heating Mantle Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Short Path Distillation Kit Specifications: Boiling Flask Size: 2L Recieving Flask Size: 250ml Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Comes Standard With The Following: Glass Components: 2L 2-Neck Boiling Flask Short Path Head Triple Neck Cow 3x 250mL Single Neck Receiving Flask 1/8" 14/20 PTFE Thermometer Adapter 1/4" 24/40 PTFE Thermometer Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever Keck Clips 3 Finger Clamp Adjustable 0-70mm Boss head 6" x 6" Scissor Jack 250-500ml Cork Stand Traceable Kangaroo Thermometer - Digital Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. Learn more about short path distillation components and FAQs with this distillation guide. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$898.40

-

Glas-Col Glas-Col Vapor Monitor

Glas-Col Vapor Monitor motor vapor temperature or other processes audible alarm - high, low, t/c break digital display Specifications TC Type "J" MUST BE ORDERED SEPARATELY Range 0 - 999 C Dimensions 4" W x 4" D x 4" H Volts 120 Includes: 6' attached power cord and grid support bracket

$414.65 $207.32

-

36" Buchner Filtration Kit

Buchner Filtration Kit This filtration kit is operated by using a vacuum pump to pull the solution through the filter paper to remove particulate. The funnel has a 36" perforated plate to support the filter paper. The 150 liter collection vessel has multiple sight glass ports so that you can easily view inside the vessel as well as hold up a flashlight if needed. The standard lid includes a pressure gauge, KF-25 vacuum port, and a valve to release vacuum pressure or add positive pressure to the vessel. The vessel has a surrounding jacket that can be used to heat or cool the solution within the main vessel, it can even be outfitted with a mixer and recovery system if desired! To build your custom setup, talk to our experienced team of account representatives. This kit includes: 36" Filtration Funnel 150L Jacketed Reactor 1.5" Butyl hose Diaphragm vacuum pump (optional)

$13,130.48

-

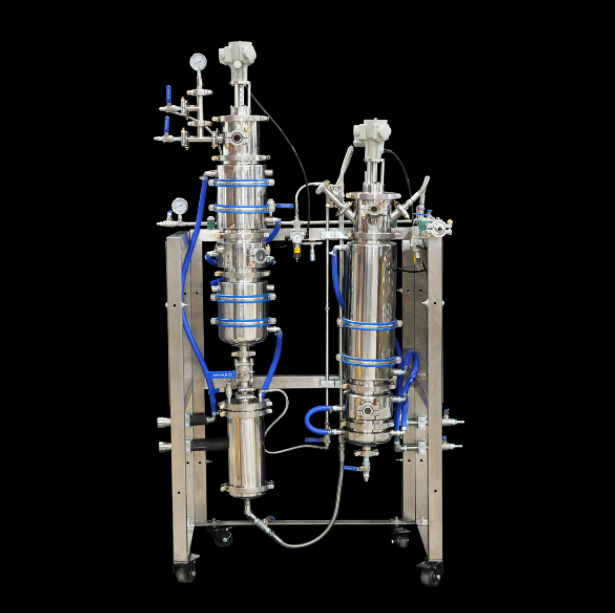

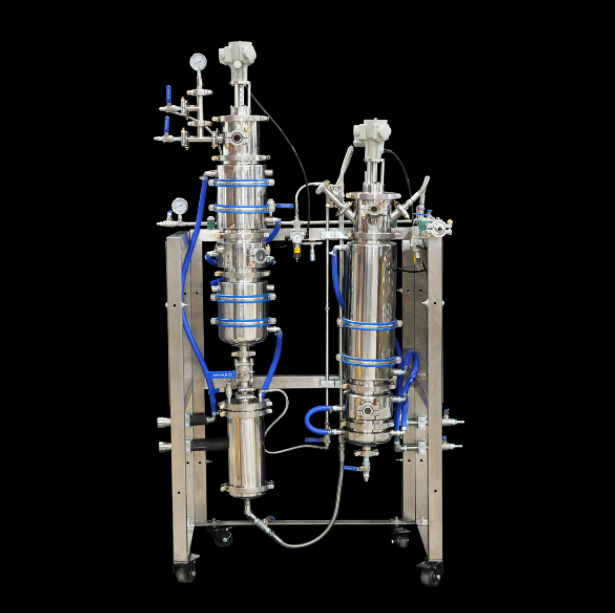

BVV 2540 Nanofiltration Skid

BVV 2540 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 2540 nanofiltration skid. Replace up to 7X 50L Rotary evaporators with a single Skid. BVV's 2540 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 30 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 2540 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 15 GPH or 30 GPH of solvent recovery. Solvents: Ethanol, Methanol Specifications 4X 2540 nanofiltration housings Stainless steel 6GPM pump with PTFE seals 7.5HP C1D1 1750 RPM Motor 7.5HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 2"x18" Heat Exchanger Polyscience 1.5HP Chiller 230/60/1/23.1 700PSI Pressure Relief Valve C1D1 Flowmeter 2X 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 30"x39"x79" Weight: 400 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$56,668.39 - $62,197.02

-

J-KEM Scientific J-KEM Model 150

J-KEM Model 150 An ideal controller for applications that don’t require the precise regulation of J-KEM’s 200-Series controllers. This compact unit packs 1200 watts of power, sufficient for 5 L heating mantles, many ovens, and other devices. Built with J-KEM’s state-of-the-art PID process controller, but does not contain J-KEM’s power control computer. Specifications: 120vac, 10 amps, 1200 wattsWarranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C) K [yellow] (-50 – 1200° C) T [blue] (-200 – 250° C) Weight: 4 Dimensions: 5.4 x 3.75 x 2.5 in PURCHASE WITH OR WITHOUT SYSTEM ACCESSORIES Complete system includes: one controller, one Teflon thermocouple (12″ long, 1/8″ diameter), one connecting cord, and one 14/20 joint adapter.

$1,042.15 - $1,199.71

-

J-KEM Scientific J-Kem Gemini-2 Dual Temperature Controller

J-Kem Gemini-2 Dual Temperature Controller Gemini-2 Dual Temperature Controller displays two temperature controllers in a single cabinet to regulate two independent reactions. Each channel is 1200 Watts MAX (1800 Watts total), 15 Amps @ 120VAC, The Gemini is one of J-KEM’s most versatile controllers featuring high power outlets and a 100 hour digital timer (on channel 1) to turn heating OFF (or ON) at a user entered time. Features Included: Over-temperature protection circuits with audible alarms, dual temperature displays, selectable operating modes, double fused, and 100% solid state design. The USB port on the back panel of the controller is an interface to J-KEM’s KEM-Net software. Safety features include: 100% solid state, double fused, audible error alarm, and over temperature circuitry that disconnects power if an over temperature condition occurs. Specifications: Dimensions: 3.5" H x 7.75" W x 8.75" D Power: 15 Amps @ 120VAC, 1200 Watts MAX/Channel, 1800 Watts (Total) Weight: 7 lbs Complete System Includes: One controller Two Teflon thermocouples (12″ long, 1/8″ diameter) Two connecting cords Two 14/20 joint adapters

$2,168.60 - $2,655.12

-

Across International Ai DigiM 10L 300C 1200 RPM Digital Heating & Stirring Mantle

Ai DigiM 10L 300C 1200 RPM Digital Heating & Stirring Mantle Across International heating and stirring mantles come standard with a digital display for the most accurate control. The large display interface makes it easy to quickly and precisely adjust temperature and rotation speeds.The DigiM mantle has two sets of thermocouples for proper temperature and speed detection. The heating jacket is pre-treated before shipment, which ensures that no smoke or odors (caused by heat) are released into your work environment. Model DigiM10 Electrical requirements 110V 60Hz 1-Phase, 2050 watts, 24A or 220V 50/60Hz 1-Phase, 2050 watts, 12A Heating Ambient to 300°C Stirring Min. speed: 110 rpm, max. speed: 1200 rpm Motor power: 40 watts Motor type: brushless DC motor Controller PID control with digital temperature and rotation speed display External thermocouple Type: PT100 Cable length: 43 inches Stainless steel probe length: 15 inches Stainless steel probe diameter: 5 mm Flask holder Maximum flask capacity: 10 liters Top opening diameter: 11.75 inches Depth: 6.5 inches Dimensions (WxDxH) Unit: 18 x 17.5 x 13 inches, shipping: 22 x 21 x 18 inches Weight Unit: 30 lbs, shipping: 40 lbs Safety Thermocouple failure protection Certification ETL tested to UL and CSA standards (optional), CE (standard) Warranty One year Standard package Part description Quantity Part image Ai DigiM 10L digital heating & stirring mantle 1 pc External temperature probeDigiM05, DigiM2, DigiM5: Cable Length: 40”, Probe Length: 9” DigiM10, DigiM20: Cable Length: 43”, Probe Length: 15” 1 pc Internal temperature plug 1 pc Boss head DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs Stainless steel support rod DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs PTFE-coated stir bar 2 pcs PTFE-coated magnetic stir bar remover 1 pc 4 prong stainless steel clamp opens to 3 1/2" DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs User's manual 1 pc

$1,644.77 - $2,750.49

-

DigiVac Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25

Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25 The DigiVac Bullseye Precision Gauge with Bluetooth is the world’s first wireless vacuum gauge featuring one-of-a-kind patented vacuum graphing and DigiVac’s ‘Vacuum Gauge’ app Versatile wireless vacuum gauge that you can monitor right from your phone or tablet (Apple ios and android) Enables remote monitoring and troubleshooting Set low and high alarm from your phone Email vacuum data to document leaks, baseline pressure or pump-downs Use battery power or standard microB-USB power Choose standard Thermocouple Plus sensor or the Upgraded Agilent 531 NPT sensor (this sensor configuration is CE and RoHs compliant), or the Agilent 536 NPT sensor which includes an integrated baffle to extend the life of the sensor by helping to protect it from contamination Portable and Precise Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs, Out-gassing or Stable Systems Includes a powerful magnet and kickstand to enable hands-free operation Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O) Calibrated under actual vacuum against a NIST standard. Graphing and Analysis Patented vacuum graphing displays vacuum and time data Visual graphing right on the display that identifies current system status Vacuum Analytics to quickly identify vacuum pressure trends Graphical display for quick determination of vacuum level Bluetooth Bullseye Gauge Applications Vacuum pump testing Baseline vacuum pump performance Transformer dry-out Schlenk line monitoring Botanical oil processing Distillations Vacuum Process Monitoring Technical Specifications Units Torr, mbar, bar, kPa, inHg, mm Hg, millitorr, microns, inches of water, PSI, Pa Control Range 1E-4 – 1000 Torr Range with Accuracy .001-5 Torr Sensor Type Agilent 531 (NPT), Agilent 536 (NPT, KF15, or KF16), VGT500 Dimensions 6.2”H x 3.7”W x 1.3”D Certifications ROHS and CE

$1,067.31 - $1,557.98

-

Beaker & Wrench Beaker & Wrench 40L Complete Dosing System

Beaker & Wrench 40L Complete Dosing System Please note: This Product has 1 week lead time For Wiped Film Evaporators The 40L Complete Dosing System by Beaker & Wrench® is a continuous feed system that connects to any Wiped Film Evaporator effortlessly. Optimize your time and end results by dialing into your feed system. The Feed Gear Pump by Beaker & Wrench® gives the operator control over flow rate and freedom to load material into the flask without breaking deep vacuum. Once attuned with the flow rate, calculations become less of a guessing game and more of a formula. Distill as slow or as fast as needed! The contents of this system include: Heated 40L feed flask Crude Cozy™ Digitally operated, heated Feed Gear Pump 4″ tri-clamp port on feed lid Inlet adapter (for your still) 6′ Heated Transfer Line (not pictured) Wattage: 90/ft, 120 Volts Maximum Temp: 150°C UL Listed 3 Channel PID Temperature Controller UL: E510826 How does it work?Crude is loaded into a heated feed flask, which then flows through the heated Gear Pump. The Gear Pump moves fluid through the gears while maintaining vacuum. Oil is then pulled towards the still body, ready for distillation! Cleaning:Every Operator has their own preference in how they clean their Wiped Film Evaporator. Ethanol, Isopropyl alcohol or vegetable oil are viable options when looking to clean your Wiped Film. Step-by-step instructions are included in the manual! Installation: Are you interested in having a Beaker & Wrench® technician install your Complete Dosing System? Click here for a quote! The advantage with having a technician perform installation is you can ask any and all questions necessary on how to process with your Wiped Film Evaporator! What is the warranty?1 year manufacturer’s warranty on parts for exchange. Customer has 5 days from day of delivery to inspect equipment for breakages or damage. ** Please indicate the inlet size of your still in the Notes section of your purchase. This will help us adapt to your set-up.

$18,659.11

-

Synder NFG Membrane (600-800Da MWCO)

Synder NFG Membrane With a pore size ranging between 0.1-10nm,Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 600-800 DA Typical Operating Flux 55-60 GFD Average Lactose Rejection: 60% Average MgSO4 Rejection: 50% Average NaCl Rejection: 10% Maximum Operating Pessure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 4-9 Ambient Temperature Operating pH Range: 4-10 Maximum Temperature Cleaning pH Range: 3-10 Ambient Temperature Cleaning pH Range: 3-10.5

$798.20 - $1,765.70

-

XL 1-Micron Refinement Filter

XL 1-Micron Refinement Filter Filter large volumes of solutions with ease with our XL 1-micron Refinement filter. complete with our 1-micron Dutch Weave sintered disk these refinement filters provide complete retentionof the filter paper making it impossible for suspended particles to bypass the filter paper. Made from the highest quality 304 stainless steel parts this XL Refinement Filter is built to last making it a great alternative to polypropylene filter trolleys. Processing Power Funnel Capacity: 44.48 Liters/11.75 Gallons Collection Capacity: 100 Liters/26.41 Gallons Specifications 12"x24" Funnel Body 12" 1um Dutch Weave Sintered Disk 12" Hemispherical Ring stand 1/2" " JIC Drain Valve 100 Liter Stainless Steel Carboy Collection Base -30Hg Vacuum Gauge 1/2" JIC Vacuum Valve 3/8" JIC Diptube Valve 1/4" JIC Butterfly Accessory Valve 350MM Ashless Filter Paper Silicone Gaskets

$4,837.55

-

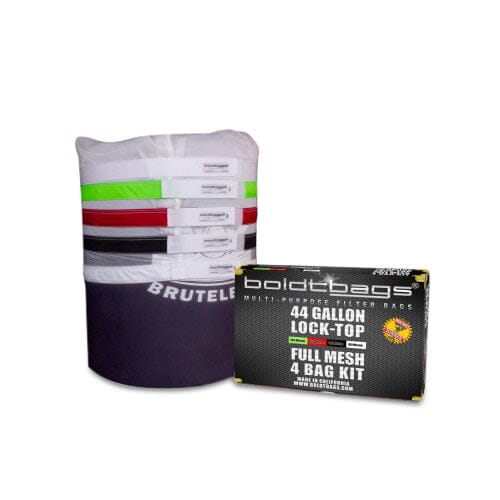

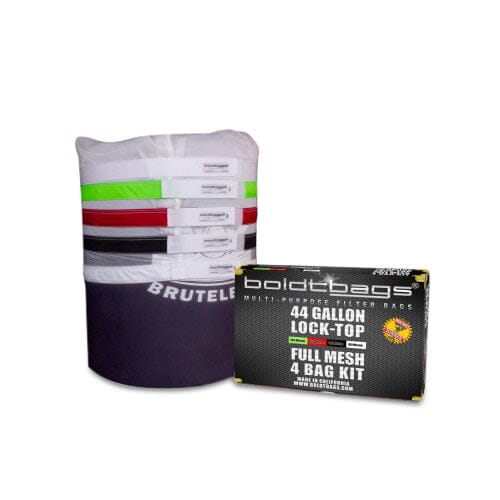

Boldtbags 44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock

44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock Lock top bags are the new product made with you in mind. Adjust your bag to the height you need and lock it in for easier product washing and collection. Custom designed with Full Mesh, these bags provide exceptional ice water sieving properties and award winning purity thanks to the large functional surface area and lightweight construction that allows for easy use and award winning results. Ideal purchase for Laboratories. Have a variety of bags to choose from and mix and match for perfect trichlome extraction. Diameter 23.5″ Depth 28.25″ 4 bag kit includes: 190 micron bag (green) 160 micron bag (red) 90 micron bag (black) 45 micron bag (white) Additional belt lock Scraping card 8 bag kit includes: 220 micron bag (blue) 190 micron bag (green) 160 micron bag (red) 120 micron bag (orange) 90 micron bag (black) 73 micron bag (yellow) 45 micron bag (white) 25 micron bag (purple) Additional belt lock Scraping card

$552.86 $345.54

-

ChemTek ChemTek CHT210R Centrifuge

ChemTek CHT210R Centrifuge CHT210R centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Each unit comes with 2 rotors for high speed(20x15ml) or large capacity94x750ml) options for refrigerated centrifuging. Specifications: Power Supply: 110V 50/60Hz Max Speed: 21,000 RPM Max RCF: 32, 752 x G Max Capacity:4x750ml Cooling Capacity: -20C to -40C Time Setting Range: 1 - 99min Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 6Kw Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves (1) Power converter

$18,244.46

-

ChemTek ChemTek CL5 Centrifuge

ChemTek CL5 Centrifuge CL5 centrifuges provide excellent performance and greater capacity. Each unit comes with 2 rotors for (6)500ml or (4)1000ml bucket options. Specifications: Power Supply: 110V 50/60Hz Max Speed: 5000 RPM Max RCF: 6100xg Max Capacity: 4x1000ml Time Setting Range: Speed Accuracy: ± 10r/min Noise: 65dB Power Consumption: 3 kW Dimensions: Net Weight: 600lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves

$24,878.81

-

Beaker & Wrench Beaker & Wrench Turn-key System 6"

Beaker & Wrench Turn-key System Please Note: Lead time 0-4 weeks Get greater consistency, purity, and confidence in every Flower oil distillation when you use our system to monitor and optimize flow rate, temperature, pressure, and wiper speed (RPM) in real time. Fully continuous flow leaves behind less advanced methods with a dependable output of 3-5 liters per hour; maximizing efficiency and minimizing complications. Be assured of the quality of your system. Each system is 6 inch and constructed with fully compliant USA NRTL-certified components, including a display unit and two sensors to track the contents of both streams of fluid as it continuously travels through the glassware. Your system arrives ready to use immediately with all components primed for use. Just roll it off the lift gate and let it get to work. Meet demand and feel confident in the quality of your output with this turn-key system. 6” Stainless Steel Wiped-Film Evaporator Delivers greater consistency, purity, and confidence in every Flower oil distillation. Continuous flow leaves behind less advanced and efficient methods with a dependable input up to 7 liters per hour. Throughput capability Up to 7.0 L/hr Average 3.0-5.0 L/hr True Continuous Feed Peristaltic Inlet pump allows addition of oil while machine is still under vacuum Outlet pumps allow dispensing of products directly into vessel of choice Feed rates adjustable from 10mL to 10L/hr Jacketed body Thermal fluid circulating through jacketed body for consistent temperature Precise temperature control PID temperature controllers on body and all heated lines for creation of precise SOPs Expert On-Site Training and Installation Validation with YOUR oil on the day of install Consultation on how to generate the best SOP for your lab Sample SOP provided for internal use Potency up to 99.8% total Flower content Feed 20L stainless steel feed flask with vacuum inlet line Peristaltic dosing pump for precise, vacuum-held dosing Feed line to evaporator is jacketed and PID controlled Short-Path Evaporator Max evaporator temperature: 200 °C 316 Stainless Steel 316 Stainless Steel Internal condenser (cold finger) 6 rollers Easy to adjust drive system speed Distillate & Residue Discharge Pumps (2 pumps) Gear pump in PID controlled heated design (design temperature 100°C), digitally displayed pump speed. Calibration and secret menu options for optimal SOP development Check valves used as a pressure lock against the atmosphere Vacuum System 21 to 36 CFM Rotary Vane Vacuum pump equipped with vacuum pump oil Diffusion vacuum pump for achieving stable vacuum conditions at low pressures (oil included) Flanged cold trap & collection vessel for cold trap Heating & Cooling by Beaker & Wrench/ Polyscience 1 independent heating unit for the evaporator (oil circulator) 1 independent heating unit (silicone pad) for the residue & distillate line 1 independent heating unit for the feed tank (silicone pad) 1 independent cooling unit for the cold trap (immersion probe) 1 independent chilling unit for the internal condenser (water circulator) Rack/Frame Frame constructed of 80/20 aluminium extrusion and equipped with 4 wheels Power supply & power distribution system 1. Voltage: 120V or 220V Frequency: 60 Hz 3. Number of Phases: 1 (two hot wires) • Power distribution panel Control panel for pumps. Included spare parts. 1 set of rollers 1 set of static gaskets 1 set of shaft sealing for rotary transmission • 1 set of bearings for rotary transmission 1 set of O-rings Documentation Operating instructions Component Certifications See Below Heaters & Chillers CE/ISO9001 Vacuum Pumps Gear Pumps Wiper Drive Power Box Frequency Box Pressure Gauge

$269,520.41

-

P10 Distillation Head - USA Made

P10 BVV™ Distillation Head P10 Distillation Head has 2 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 2 vigreux to allow for more packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$1,105.72 $829.29

-

Across International Ai DigiM 20L 300C 1200 RPM Heating & Stirring Mantle - 220V

Ai DigiM 20L 300C 1200 RPM Heating & Stirring Mantle - 220V Across International heating and stirring mantles come standard with digital display for the most accurate control. The large display interface makes it easy to quickly and precisely adjust temperature and rotation speeds.The DigiM mantle is equipped with two sets of thermocouples for proper temperature and speed detection. The heating jacket is pre-treated before shipment, which ensures that no smoke or odors (caused by heat) are released into your work environment. Model DigiM20 Electrical requirements 220V 50/60Hz 1-Phase, 2900 watts, 13.2 A Heating Ambient to 300°C Stirring Min. speed: 110 rpm, max. speed: 1200 rpm Motor power: 40 watts Motor type: brushless DC motor Controller PID control with digital temperature and rotation speed display External thermocouple Type: PT100 Cable length: 43 inches Stainless steel probe length: 15 inches Stainless steel probe diameter: 5 mm Flask holder Maximum flask capacity: 20 liters Top opening diameter: 14.5 inches Depth: 7.5 inches Dimensions (WxDxH) Unit: 20.5 x 20.5 x 13 inches, shipping: 24 x 24 x 18 inches Weight Unit: 40 lbs, shipping: 50 lbs Safety Thermocouple failure protection Certification ETL tested to UL and CSA standards (optional), CE (standard) Warranty One year Standard package Part description Quantity Part image Ai DigiM 20L digital heating & stirring mantle 1 pc DigiM20: Cable Length: 43”, Probe Length: 15” 1 pc Internal temperature plug 1 pc Boss head DigiM20: 2 pcs 2 pcs Stainless steel support rod DigiM20: 2 pcs 2 pcs PTFE coated stir bar 2 pcs PTFE coated magnetic stir bar remover 1 pc 4 prong stainless steel clamp opens to 3 1/2" DigiM20: 2 pcs 2 pcs User's manual 1 pc

$2,197.63 - $2,957.81

-

Beaker & Wrench 12" Wiped-Film

Beaker & Wrench 12" Wiped-Film Beaker & Wrench continues to be an industry leader, bringing together scientific expertise and real-world industry experience. Take the guess-work out of large scale distillation with their Wiped-Film Evaporation Turn-Key System. It arrives fully functional, meaning you can take advantage of the latest technology immediately and without additional installation or training costs. Other control processes can be subjective and vulnerable to user error, but their automated Wiped-Film Evaporation Turn-Key System will help maximize your product outcomes with greater productivity and maximum purity. 12” Wiped Film Measurements:76”[1.9m] x 30”[0.762m] x 85”[2.16m] Integrated 23″ Touch-Screen Control 200LFeed Tank ACS 100 60 CFMDry Screw Vacuum Pump Dual Stage Cold Trap-50/-100C Inlet and Outlet Gear Pumps(continuous flow) Single-Plug 240V Three-Phase to power the entire machine Six Zone Evaporator Body(1.1m² evaporative area) Consistency is Key Get greater consistency, purity, and confidence in every cannabis oil distillation when you use our system to monitor and optimize flow rate, temperature, pressure, and wiper speed (RPM) in real time. Then… NRTL Certified Each system is 6“ or 12” and constructed with fully compliant USA NRTL-certified components, including a display unit and two sensors to track the contents of both streams of fluid as it continuously travels through the glassware. Get started rapidly with… Set it and Forget it Fully continuous flow leaves behind less advanced methods with a dependable output of 15-30 liters per hour; maximizing efficiency and minimizing complications. Be assured of the quality of your system because we’re… Easy Installation Your system arrives ready to use immediately with all components primed for use. Just roll it off the lift gate and let it get to work. Meet demand and feel confident in the quality of your output with this turn-key system. Don’t make it complicated. Get it right. Lead time: 8-12 weeks from date of payment of 50% deposit, 50% due prior to shipping Specifications Skid Frame: + Dimensions (LxWxH): 76”[1.9m] x 30”[0.762m] x 85”[2.16m] + Weight:1,000 lbs [450Kg] + Material: Extruded Aluminum + 6” castors w/ brakes Shipping Information: + Dimensions (LxWxH): 82.5”[2.01m] x 36.5”[0.93m] x 87.5”[2.22m] + Total Weight: 1200 lbs [545Kg] Electrical Power Distribution Box: + Plug: SCAME SCM563P6W + Input Voltage: 240VAC 3 Phase with Neutral 60 Hz + External Circuit breaker: 60 amp + Nominal current: 24 amps Control Interface + Custom 27” high definition touch screen interface + automated controls + recipe folder +automated sensors and safeties +Error reporting +Software controlled Emergency shutdown Feed Tank: + Volume: 200 Liter + Material: 316 Stainless Steel + double jacketed + Max Temp: [95°C] + Heater: water jacket with 2500kW heater Feed Hose: + Length: 7’-0” [2.13m] + Voltage: 120VAC + Amps: 4.5 Amps + Max Temp: 450°F[220°C] + K-type sensor Rotor: + Wipers: PTFE (Polytetrafluoroethylene) + Mesh Baffles: 316 Stainless Steel + Motor Voltage: 240VAC + Motor Amps: 4(Max) + Motor Watts: 1kw (Continuous) + Speed: 0-400RPM + Dust and Splash Resistant Still Body / Wiped Film Evaporator: + Evaporation Surface Area: 1.1m² + Materials: 316 Stainless Steel + Heat Source: multi-zone Heat Band with independent thermocouples and control + Maximum Power: 12kWatts + Feed Inlet: KF25 + Top and Bottom Connections: 12” sanitary flange + Insulation jacket included Internal condenser: + multi-finger hairpin condenser + Materials: 316 Stainless Steel + Vacuum port: NW80 + Distillate port: KF25 + Residue port: 1.50” Tri-clamp + 2,500w heater + Cooling capacity 8,000w @80c Residue heater: 120VAC, 0.78 amp, 150°C Max Temp, K-type sensor 90W, UR Recognized Heat Pad Residue Outlet Conical shaped Mesh cleanable filter Dual heat pads Clog SensorLiquid level sensor Led lights Condenser Circulator: + Model: BWC-A120 + Bath Volume: ~12L + Bath Fluid: Beaker Kool + multi-fan & Radiator cooling system + Temperature range: 25 to 90°C + Temperature stability: ±1 °C + Heating capacity: 2.5 kW +Cooling capacity: 8kw @80c Gear Pumps: + Voltage: 48VDC + Amperage: 5A + Max Rate: 50.0 L/Hr + Heater: 120v, 0.5amp, 120°C Max Temp, K-type sensor + 45w, UL Recognized Heat Pad + Check Valve Included Dual Stage Cold Trap: + 2 stage cold trap optimized for maximum vacuum protection + Model: Huber TC100 & -100C + CC 508 -50C (1.5kw cooling @ 0c) + Temperature Range: -100 to 100°C Vacuum Gauge: + Model: KJ Lesker

$656,524.08

-

ChemTek ChemTek - Snow Queen Oil Filtration

ChemTek - Snow Queen Oil Filtration Create isolate in minutes Redissolve and reformulate Dual Mixer

$34,553.90

You have seen 75 out of 75 products